+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

The utilization of Rod End Cylinders in industrial applications has seen significant growth, with projections indicating an increasing demand driven by advancements in automation and manufacturing processes. According to the latest report by the Industrial Automation Institute, the market for Rod End Cylinders is expected to expand by approximately 12% annually through 2025, as industries strive for efficiency and precision. This highlights the vital role these components play in various sectors, including automotive, aerospace, and material handling, where motion control is paramount.

As industry experts have noted, the versatility and reliability of Rod End Cylinders make them indispensable. Dr. Emily Carter, a leading authority in hydraulic systems, states, "Rod End Cylinders are essential for enhancing mechanical performance and ensuring operational efficiency in modern industrial settings." Her insights underscore the importance of selecting the right cylinder for specific applications, given that they can significantly affect noise reduction, energy consumption, and overall system longevity.

In the following sections, we will explore the top applications of Rod End Cylinders in 2025, delving into their benefits and the innovative developments shaping their future in industrial landscapes. By examining real-world applications and expert testimonials, we aim to provide a comprehensive understanding of how Rod End Cylinders can transform operational capabilities for various industries.

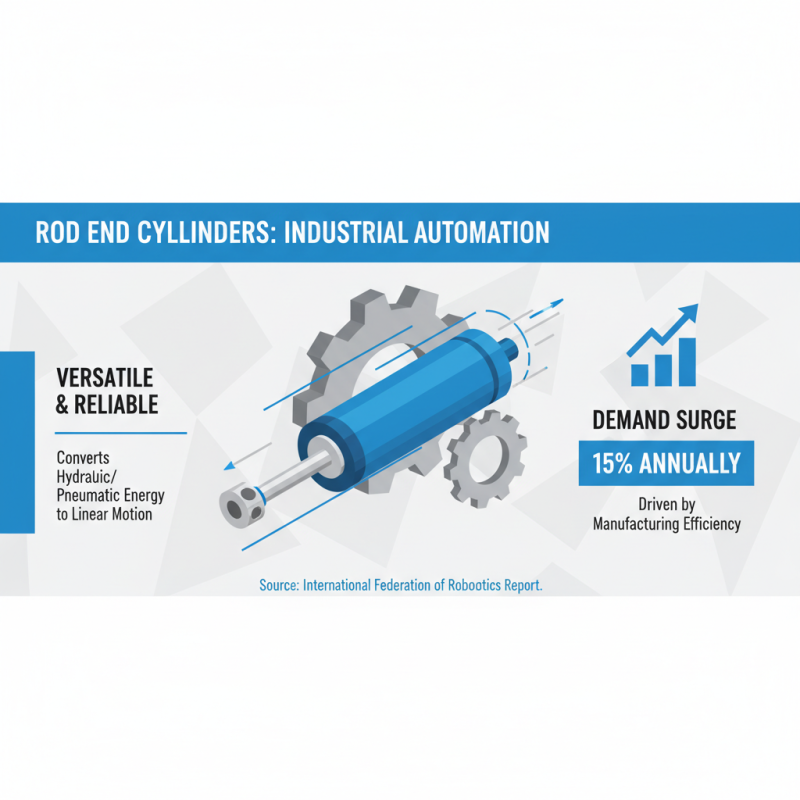

Rod end cylinders are increasingly becoming a vital component in various industrial applications due to their versatile functionality and reliability. These cylinders are crucial in facilitating motion through the conversion of hydraulic or pneumatic energy into linear movement. According to a report by the International Federation of Robotics, the demand for automation solutions, including rod end cylinders, has surged by 15% annually, driven mainly by the need for efficiency in manufacturing processes.

One of the top applications for rod end cylinders is in the automotive sector, where they are used in assembly lines for tasks such as lifting and positioning components. A 2022 market analysis indicates that nearly 30% of rod end cylinder usage is within this industry, highlighting their importance in automation and precise control. Additionally, in the material handling sector, these cylinders provide the necessary force to move heavy loads with accuracy, reducing manual labor and enhancing operational safety. The market for material handling equipment, which incorporates rod end cylinders, is projected to reach $200 billion by 2025, reflecting the growing need for effective solutions in logistics and warehousing.

In the realm of robotics and automation, rod end cylinders play a pivotal role in enhancing the functionality of robotic arms, particularly in industries such as pharmaceuticals and food processing. Research shows that the global industrial robotics market is expected to grow by over 12% CAGR through 2025, with rod end cylinders being integral to the performance of these advanced systems. The adaptability and precision of rod end cylinders significantly contribute to improved production rates and reduced downtimes, affirming their position as key components in contemporary industrial applications.

Rod end cylinders are increasingly popular in various industrial applications due to their exceptional efficiency and durability. One of the primary benefits of these cylinders is their ability to provide precise motion control in confined spaces. Their compact design allows for seamless integration into machinery, which reduces the need for extensive modifications and optimizes space usage. This feature not only improves the overall performance of industrial systems but also leads to significant time and cost savings during installation and maintenance.

Furthermore, the materials used in manufacturing rod end cylinders typically exhibit high resistance to wear and environmental stressors. This ensures a longer operational lifespan and reduces the frequency of replacements, contributing to lower maintenance costs over time. The reliability of these cylinders under heavy loads and dynamic conditions enhances productivity, as downtime for repairs or replacements is minimized. Overall, the use of rod end cylinders in industrial settings greatly contributes to enhanced operational efficiency and durability, establishing them as a vital component in modern automation and manufacturing processes.

Rod end cylinders have become integral components across various industries due to their versatility and efficiency. In the automotive sector, these cylinders are often designed to provide precise movement in steering and suspension systems. Their ability to handle dynamic loads and harsh environments makes them ideal for applications like power steering and suspension linkages, where both strength and responsiveness are crucial. The design choices in these applications typically emphasize lightweight materials without compromising durability, achieving an optimal balance between performance and safety.

In the manufacturing and packaging industries, rod end cylinders serve pivotal roles in automation and material handling systems. These designs are typically structured for high cycle rates and reliable operation, accommodating various payloads and ensuring precision in repetitive tasks. Adopting configurations that allow for compact installation and easy maintenance can significantly enhance productivity. The emphasis here is on the ability to withstand continuous use and to facilitate smooth, controlled movements which are foundational in assembly lines and robotic applications. By customizing rod end cylinder designs to meet the specific requirements of each industry, manufacturers can maximize operational efficiency and provide innovative solutions tailored to their unique challenges.

| Application | Industry | Benefits | Design Type |

|---|---|---|---|

| Material Handling | Logistics | Increased efficiency, reduced wear | Standard |

| Robotics | Manufacturing | Precision movement, enhanced control | Precision |

| Agricultural Machinery | Agriculture | Durability, weather resistance | Heavy Duty |

| Construction Equipment | Construction | High load capacity, reliability | Dual Bearing |

| Hydraulic Systems | Energy | Improved flow, efficient operation | Compact |

To ensure the optimal performance of rod end cylinders in industrial applications, regular maintenance is essential. These components are critical for effective motion control and load manipulation, so any downtime due to mechanical failure can lead to significant productivity losses. Implementing a proactive maintenance regime will not only extend the lifespan of the cylinders but also enhance their efficiency.

One key tip is to regularly inspect the rod end for signs of wear or damage. This includes checking for any scratches, pitting, or deformation that could affect the performance. Additionally, ensure that the cylinder is properly lubricated; using the right type and amount of lubricant can greatly reduce friction and wear on moving parts. It’s advisable to set a maintenance schedule based on the frequency of usage and the operating conditions, as frequent inspections can help catch potential issues before they escalate.

Another important aspect of maintenance involves the alignment of the rod end cylinder. Misalignment can lead to uneven load distribution and increased stress on the components. Ensuring proper installation and alignment can mitigate these risks. Lastly, consider conducting regular performance assessments to identify any drop in efficiency; this can help pinpoint areas that require attention or adjustment, thereby maintaining the cylinder's optimal functionality over time.

The future of rod end cylinder technology in manufacturing is poised for significant advancements driven by ongoing trends in automation, materials science, and smart manufacturing. Automation remains a dominant force, as industries increasingly adopt robotics and automated systems to enhance productivity and reduce labor costs. These systems necessitate highly reliable and efficient rod end cylinders that can withstand the demands of fast-paced operations. As the complexity and capabilities of these automated systems grow, so too will the need for rod end cylinders capable of providing precise motion control, adaptability, and durability.

Moreover, the integration of advanced materials and coatings is set to revolutionize the design and performance of rod end cylinders. Innovations in lightweight materials, such as composites and high-strength alloys, promise to reduce overall weight and improve efficiency without compromising structural integrity. Coupled with enhanced surface treatments that provide superior wear resistance and corrosion protection, these developments will enable rod end cylinders to operate effectively in harsher environments, extending their lifespan and reducing maintenance costs.

As these trends evolve, the manufacturing sector can expect rod end cylinders to become increasingly efficient and versatile, meeting the demands of a rapidly changing industrial landscape.