+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In an era where industrial efficiency and performance are paramount, advancements in technology play a crucial role in driving innovation. One such area that is capturing the attention of engineers and industry leaders alike is the hydro cylinder. Hydro cylinders are essential components in various applications, providing critical force and motion control in hydraulic systems. As industries strive to enhance productivity and minimize operational costs, the demand for more efficient and high-performing hydro cylinder solutions has never been greater.

This article aims to explore the top five innovative hydro cylinder technologies expected to revolutionize performance across diverse industrial sectors by 2025. From advanced materials that improve durability to smart technology that optimizes functionality, these innovations promise to reshape how hydraulic systems operate. By examining these cutting-edge developments, we will highlight the potential benefits they can bring to industries keen on harnessing the power of hydro cylinders for improved efficiency and effectiveness.

Join us as we delve into the future of hydro cylinder technology and discover how these breakthroughs can elevate industrial operations to new heights.

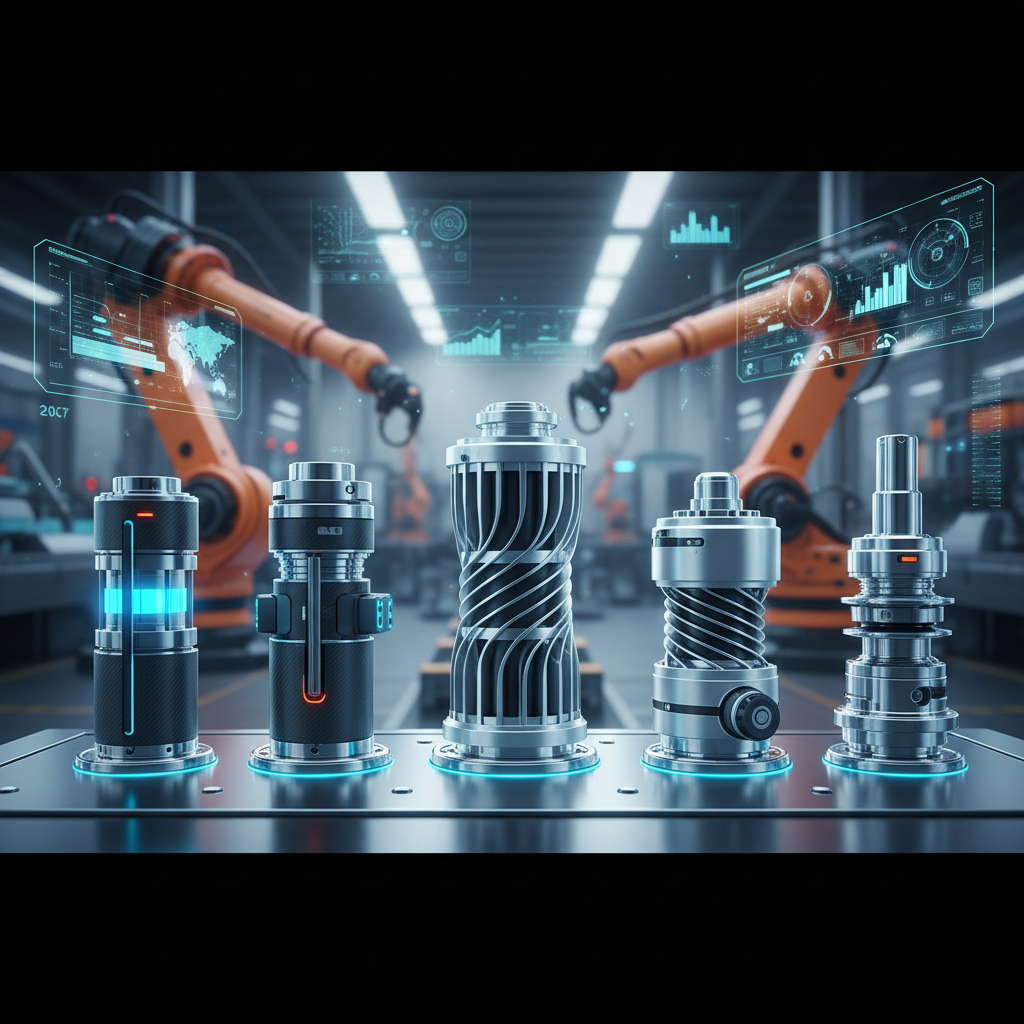

Emerging trends in hydro cylinder design are increasingly focused on enhancing efficiency and performance across various industries. Recent innovations in hydraulic components, particularly through metal additive manufacturing, have transformed traditional designs, leading to improved functionality and reduced material waste. According to industry analyses, the global hydraulics market is projected to grow significantly, reaching an estimated USD 49.23 billion by 2033, with a CAGR of 2.8%. This growth is driven by the adoption of advanced manufacturing techniques that allow for more intricate and optimized hydro cylinder designs.

Furthermore, the automotive hydraulic systems market is at the forefront of these advancements, critical for boosting overall vehicle performance. Reports indicate that the slave cylinders market, essential for optimizing hydraulic functions within vehicles, is expected to experience substantial growth from 2025 to 2032. As more industries adopt these innovative technologies, the demand for efficient hydraulic systems, capable of delivering high performance while minimizing environmental impact, will continue to rise, paving the way for a more sustainable future in hydraulic applications.

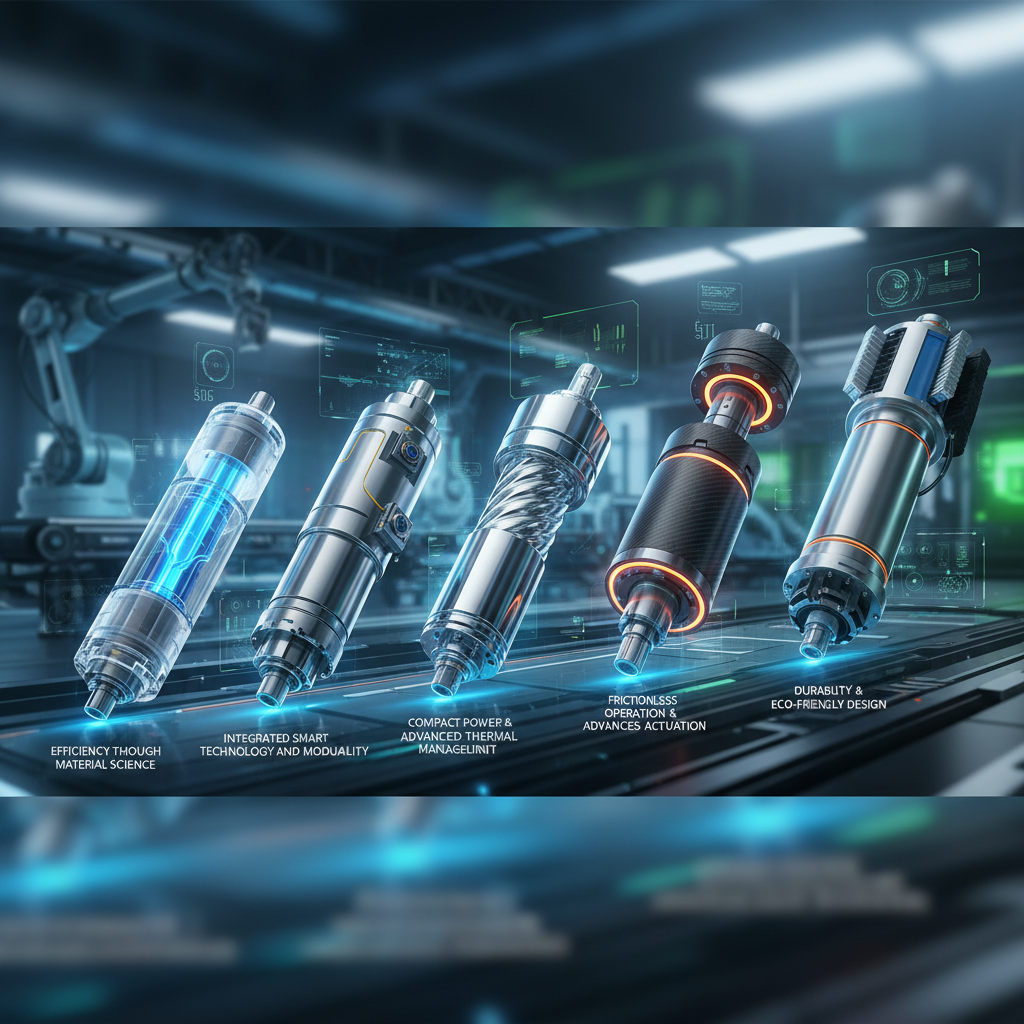

In the rapidly evolving landscape of industrial applications, the innovation of hydro cylinders is critical for enhancing efficiency and performance. Game-changing materials are at the forefront of this evolution, with advanced composites and high-strength alloys emerging as key drivers. According to a report by MarketsandMarkets, the global hydraulics industry is expected to reach USD 58.1 billion by 2025, fueled by the increasing demand for more durable and efficient hydraulic systems. The integration of lightweight materials not only reduces the overall weight of hydro cylinders but also improves energy efficiency, leading to significant operational cost savings.

Specialized coatings and treatments have also transformed the performance capabilities of hydro cylinders. For instance, the adoption of nanotechnology in surface coatings has been shown to enhance resistance to wear and corrosion, crucial for sectors such as construction and automotive. A study from Research and Markets highlights that the advanced material market for hydro cylinders is projected to grow by over 15% annually, reflecting the industry's shift towards sustainability and increased operational lifespan. This trend underscores the importance of innovation in materials as a central theme in driving future advancements in hydro cylinder technology across diverse industrial applications.

The integration of automation and smart technology into hydro cylinder systems is revolutionizing efficiency and performance across various industries. By incorporating advanced sensors and IoT connectivity, these systems can now provide real-time data monitoring and feedback, allowing for timely adjustments and maintenance. This not only minimizes downtime but also enhances the operational efficiency of hydraulic mechanisms, leading to more reliable and versatile applications in sectors such as manufacturing, construction, and automotive.

Furthermore, the implementation of machine learning algorithms enables hydro cylinders to adapt their performance based on historical data and predictive analytics. This allows for proactive maintenance schedules that can prevent unexpected failures and optimize energy consumption. Moreover, intelligent control systems can facilitate seamless integration with other automated machinery, paving the way for a more cohesive and efficient workflow.

As manufacturers continue to embrace these innovations, the potential for enhanced productivity and reduced operational costs in industrial applications is substantial.

The increasing demand for sustainability in industrial operations has led to significant innovations in hydro cylinders, aiming to reduce their environmental impact. One of the major advancements is the development of biodegradable hydraulic fluids, which replace conventional oils that can be harmful to ecosystems. By using these eco-friendly alternatives, industries not only comply with stringent environmental regulations but also minimize the risk of contamination in case of leaks.

Another notable innovation is the integration of smart technology within hydro cylinders. These smart systems enable real-time monitoring of performance metrics, ensuring optimal operation while minimizing energy wastage. By analyzing data such as pressure, temperature, and fluid levels, industries can proactively address maintenance needs, extending the lifecycle of the equipment and reducing resource consumption. Furthermore, designs are moving towards recyclable materials, decreasing the overall carbon footprint associated with hydro cylinder production and disposal. These innovations collectively contribute to a more sustainable industrial framework, aligning operational efficiency with environmental responsibility.

The advancements in hydro cylinder technology are crucial for boosting efficiency and performance across various industries. Performance metrics are essential in gauging the effectiveness of these innovations. Key performance indicators (KPIs) such as cycle time reduction, energy consumption, and maintenance intervals serve as benchmarks for assessing the impact of new hydro cylinders. For instance, a recent industry report indicated that implementations of advanced hydro cylinder systems can lead to a 20% reduction in energy usage while increasing operational throughput by up to 30%. These statistics highlight the potential of innovative designs to transform industrial processes.

When considering the integration of these new technologies, it's vital to track performance metrics closely. Regular assessment can help identify potential areas for improvement and ensure that the technology is delivering as promised. **Tip:** Utilize real-time monitoring systems to analyze hydraulic efficiency and respond promptly to any deviations in performance. Moreover, conducting regular training for operators on the latest innovations maximizes the potential benefits of these systems, offering a more profound understanding of how to exploit these technologies effectively.

As industries continue to adopt these innovations, the importance of measuring their performance cannot be overstated. **Tip:** Establish a routine evaluation plan based on qualitative and quantitative metrics to consistently gauge the effects of new hydro cylinder technologies. Staying informed and proactive will empower industries to harness these advancements optimally, leading to substantial gains in productivity and cost savings.

| Innovation | Key Features | Efficiency Improvement (%) | Performance Metrics | Average Lifecycle (Years) |

|---|---|---|---|---|

| Smart Control Systems | Real-time monitoring, adaptive response | 20% | Response Time, Energy Consumption | 10 |

| Lightweight Materials | High-strength alloys, reduced weight | 15% | Durability, Load Capacity | 12 |

| Eco-friendly Fluids | Biodegradable and low toxicity | 25% | Environmental impact, Performance | 8 |

| Sealed Cylinder Technology | Increased durability, reduced leakage | 30% | Maintenance Frequency, Efficiency | 15 |

| Adaptive Pumping Technology | Variable speed control, optimized flow | 18% | Flow Rate, Energy Efficiency | 11 |