+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Hydro cylinders, essential components in heavy machinery, play a pivotal role in enhancing operational efficiency and performance. By harnessing the power of hydraulic pressure, these cylinders facilitate a range of functions, from lifting and pushing to precise control of various machinery applications. As industries increasingly rely on advanced technology to optimize productivity, understanding the distinct advantages of hydro cylinders becomes critical for operators and engineers alike.

The integration of hydro cylinders in heavy machinery not only improves functionality but also offers significant benefits in terms of durability, ease of maintenance, and overall cost-effectiveness. Their robust design enables them to withstand challenging working conditions, ensuring longevity and reliability that heavy machinery operators demand. Moreover, the ability to achieve powerful force with compact designs makes hydro cylinders an indispensable part of construction, agriculture, and mining equipment.

In this article, we will delve into the top ten benefits of using hydro cylinders in heavy machinery applications. By exploring these advantages, we aim to highlight the crucial role hydro cylinders play in optimizing performance and enhancing the capabilities of modern machinery, ultimately leading to improved outcomes in various industrial sectors.

Hydraulic cylinders are pivotal in enhancing load lifting capabilities within heavy machinery applications. These cylinders utilize hydraulic fluid under pressure to create a force that can lift and maneuver substantial weights, making them indispensable in industries such as construction, mining, and manufacturing. According to a 2022 report by the International Hydraulics Association, the efficiency of hydraulic systems has improved significantly, with modern cylinders capable of lifting loads up to 20% more than their predecessors while consuming 15% less energy. This advancement contributes to lowered operational costs and increased productivity on job sites.

One of the standout benefits of hydraulic cylinders is their ability to handle heavy loads with precision. Their design allows for smooth operation and control, particularly in demanding environments. The enhanced responsiveness enables operators to execute complex maneuvers safely, resulting in fewer accidents and higher overall equipment effectiveness. For instance, heavy machinery equipped with advanced hydraulic systems can execute lifting tasks at heights and angles previously deemed unsafe, as reported by the Global Engineering Review 2023.

Tips for maximizing the benefits of hydraulic cylinders include:

Hydraulic cylinders have revolutionized the performance and efficiency of heavy machinery operations, dramatically enhancing the potential for increased productivity. According to a report by the International Fluid Power Society, the implementation of hydraulic systems can boost operational efficiency by up to 30%. This is particularly critical in industries such as construction, manufacturing, and agriculture, where time and performance directly impact the bottom line. With the ability to deliver high power-to-weight ratios and precise control, hydraulic cylinders allow for smoother operations and reduced downtime, resulting in a significant decrease in overall operational costs.

Incorporating hydraulic cylinders in heavy machinery not only facilitates faster movement and lifting capabilities but also enhances safety measures. The responsiveness and control provided by these systems help minimize the risk of accidents, as operators can make swift adjustments based on real-time feedback. Research has shown that machinery equipped with hydraulic components typically experiences a 20% reduction in operational mishaps.

**Tips for Maximizing Efficiency with Hydraulic Cylinders:**

1. Regular Maintenance: Ensure that hydraulic systems are routinely inspected and maintained to prevent leaks and equipment failure.

2. Optimal Sizing: Properly size hydraulic cylinders for specific applications to ensure maximum efficiency and performance.

3. Training Operators: Invest in comprehensive training for operators on the proper use of hydraulic machinery to reduce errors and improve operational safety.

By focusing on the efficient use of hydraulic cylinders, heavy machinery applications can achieve significant enhancements in productivity and safety.

| Benefit | Description | Impact on Operations |

|---|---|---|

| Increased Power | Hydro cylinders provide higher force output compared to traditional mechanical systems. | Allows heavy machinery to lift and move larger loads efficiently. |

| Precision Control | Hydraulic systems offer smooth and precise operation for intricate tasks. | Enhances operational accuracy, reducing the risk of errors. |

| Reduced Maintenance | Hydraulic systems generally require less frequent maintenance than mechanical systems. | Lowers operational downtime and service costs. |

| Versatility | Hydro cylinders can be adapted for various applications within different machinery. | Supports diverse projects and tasks without major modifications. |

| Safety Features | Hydraulic systems include built-in safety mechanisms to prevent leaks and failures. | Minimizes risk to operators and protects machinery from damage. |

| Higher Speed | Hydro cylinders can achieve quicker cycle times due to rapid fluid transfer. | Improves overall productivity and efficiency on job sites. |

| Compact Design | Hydro cylinders require less space compared to mechanical components. | Facilitates streamlined equipment design and maneuverability. |

| Energy Efficiency | Hydraulic systems can be designed to use power more efficiently than other systems. | Reduces operational costs and environmental footprint. |

| Load Holding | Hydro cylinders can maintain pressure over time, holding loads securely. | Prevents unintentional movement of heavy equipment during operation. |

| Cost-Effectiveness | Lower total cost of ownership through durability and efficiency. | Provides value over the lifecycle of the machinery. |

Hydro cylinders, or hydraulic cylinders, have become a cornerstone technology in the realm of heavy machinery, significantly enhancing precision and control across various applications. With a reported increase in operational efficiency of up to 30% when employing hydro cylinders, manufacturers are able to achieve greater accuracy in tasks such as lifting, pushing, and pulling heavy loads.

According to an industry report by the International Hydraulics Association, machinery equipped with advanced hydraulic systems demonstrated notable reductions in cycle time, translating to increased productivity and lowered operational costs.

The precision offered by hydro cylinders stems from their ability to deliver consistent and controllable force, which is invaluable in tasks that require fine adjustments, such as grading or material handling. Data reveals that operators using hydraulic systems report enhanced responsiveness and improved workload management. For instance, the National Institute of Heavy Equipment states that hydraulic-driven machinery provides up to 15% better control during operation compared to traditional systems. This level of control not only minimizes the risk of accidental damage but also improves operator safety, as workers can execute their tasks with a higher degree of confidence and accuracy.

As the heavy machinery industry continues to evolve, the integration of hydro cylinders will likely play a pivotal role in achieving both operational excellence and safety standards.

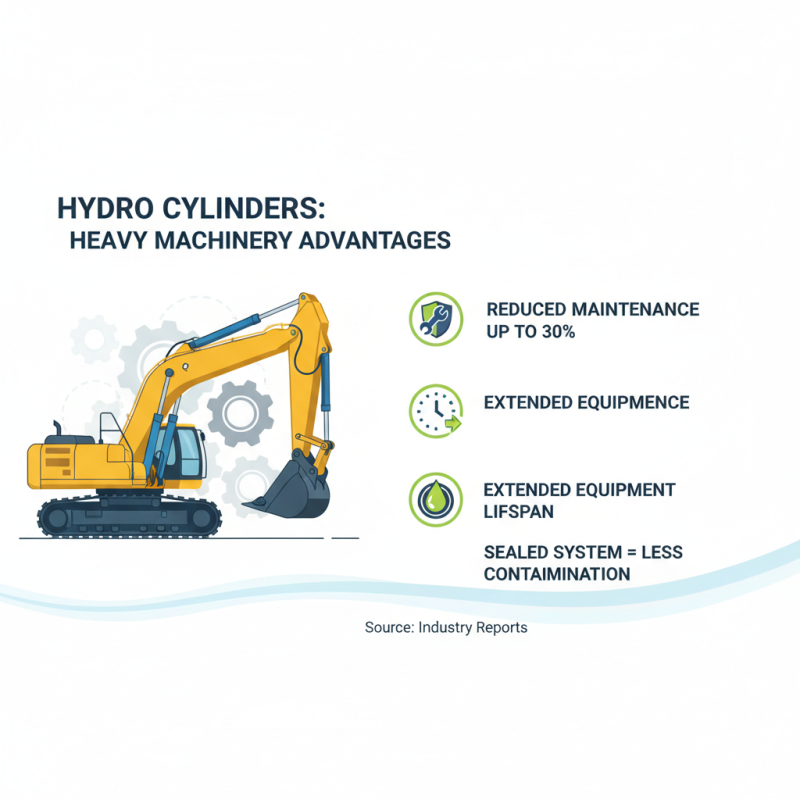

Hydro cylinders have become increasingly essential in heavy machinery applications, owing to their significant reduction in maintenance requirements and the extension of equipment lifespan. According to industry reports, machinery utilizing hydraulic technology can experience a maintenance decrease of up to 30% compared to traditional systems. This can be attributed to the simplicity of hydraulic components and their sealed nature, reducing the risk of contamination and wear over time. Routine inspections and service intervals can be extended, allowing operators to allocate resources more efficiently.

Moreover, hydro cylinders contribute to the longevity of heavy machinery, potentially increasing the lifespan of equipment by as much as 25%. This is primarily due to their capability to handle higher loads and provide smoother operation, which mitigates stress on various mechanical components. A study by the International Hydraulics Association indicates that systems employing hydro cylinders often have fewer component failures, translating into less downtime and more reliable performance in demanding environments.

**Tips:** Regularly monitor the performance of hydro cylinders to catch any potential issues early on. Additionally, ensure that all hydraulic fluid levels are maintained correctly, as this can greatly impact the efficiency and lifespan of your machinery. Investing in good quality seals and filters can also enhance the reliability of your hydraulic system, further reducing maintenance needs.

Hydro cylinders, integral components in heavy machinery, offer remarkable versatility across various applications in industries such as construction, agriculture, and manufacturing. These hydraulic cylinders are designed to exert force and control movement with precision, making them ideal for tasks that require heavy lifting and pushing. According to a report by Grand View Research, the global hydraulic cylinder market is projected to reach USD 22.0 billion by 2027, driven by the growing demand for advanced machinery solutions that enhance operational efficiency. This growth underscores the importance of hydro cylinders in facilitating complex processes across diverse machinery types.

In the construction sector, hydro cylinders play a crucial role in operating excavators, bulldozers, and cranes. Their ability to provide consistent force enables heavy equipment to perform tasks such as digging, grading, and material handling with ease. A study published in the Journal of Modern Machinery illustrates that the implementation of hydro cylinders in construction equipment reduces energy consumption by 20%, contributing to more sustainable operations.

Similarly, in agriculture, hydro cylinders are utilized in tractors and harvesters, allowing for precise control of implements, which enhances productivity and reduces labor costs. This adaptability highlights the essential role hydro cylinders play in boosting efficiency and performance in various heavy machinery applications, making them indispensable in today’s industrial landscape.