+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

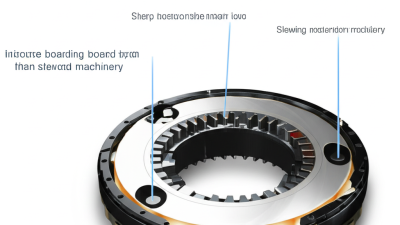

In the rapidly evolving landscape of modern machinery, the significance of Slewing Rings has come to the forefront, enhancing operational efficiency and precision. According to a report by Research and Markets, the global slewing bearing market is projected to reach $14.3 billion by 2026, growing at a CAGR of 5.2%. This growth is largely driven by the increasing demand for heavy equipment in sectors such as construction, mining, and renewable energy.

Slewing Rings enable smooth and controlled rotational movements in machines, which is crucial for applications such as cranes, wind turbines, and excavators. Their ability to withstand heavy loads while providing reliability in movement makes them an integral component in ensuring the overall productivity of modern machinery. Understanding how to leverage the benefits of Slewing Rings can not only enhance operational efficiency but also facilitate innovations in design and functionality across various industries.

Slewing rings are crucial components in modern heavy machinery, providing a reliable means of rotation and support for various applications. Their design allows for high load capacities and exceptional precision, which are essential qualities in machinery operating under demanding conditions. By integrating slewing rings, manufacturers can enhance the overall efficiency and effectiveness of their equipment, leading to more precise operations in industries such as construction, mining, and manufacturing.

When utilizing slewing rings, consider these tips to maximize their benefits: First, ensure proper alignment during installation to prevent uneven wear and potential failure. Regular maintenance checks are essential to identify any signs of damage or wear, extending the lifespan of the component. Additionally, selecting the right size and load rating for your specific application will optimize performance and improve precision.

As the global bearings market continues to expand, the importance of innovative technologies like slewing rings cannot be overstated. Their ability to enhance precision and reliability makes them a valuable investment in the ongoing evolution of heavy machinery operations. With projected market growth, it’s clear that slewing rings will play a vital role in shaping the future of industrial applications.

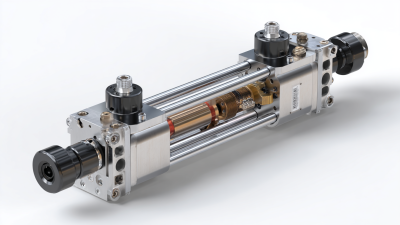

Slewing rings, also known as turntable bearings, are pivotal in modern machinery, particularly due to their ability to support large loads and enhance rotational movement. Key performance metrics for these components include load capacity and lifespan, which are critical for determining their suitability for various applications. The load capacity of slewing rings is influenced by factors such as design, materials used, and the specific application they’re intended for. A higher load capacity allows for the support of heavier equipment, making slewing rings indispensable in industries ranging from construction to aerospace.

Tip: When selecting a slewing ring, always consider the maximum load it will bear in its specific application to ensure durability and efficiency.

Lifespan is another crucial aspect, as it directly affects maintenance costs and equipment reliability. A well-manufactured slewing ring can withstand years of operation if properly maintained. Factors affecting lifespan include the operating conditions, frequency of use, and lubrication practices. Regular inspections and timely lubrication are essential in extending the longevity of these components.

Tip: To maximize the lifespan of slewing rings, implement a routine maintenance schedule that includes checks on lubrication levels and any signs of wear.

Slewing rings, integral components in modern machinery, offer significant cost efficiency by minimizing maintenance expenses. These robust bearings allow for smooth rotation and support heavy loads, making them ideal for various applications, from construction equipment to wind turbines. By choosing slewing ring technology, businesses can reduce the frequency and cost of machine downtimes associated with traditional bearing systems. This translates to lower maintenance budgets and longer equipment lifespan.

Tip: Regularly inspect and lubricate your slewing rings to prevent wear and tear. Simple maintenance checks can catch potential issues before they escalate, ensuring optimal performance and longevity.

Another advantage of slewing rings is their compatibility with automation systems, which can further enhance efficiency. Automation reduces human error and improves precision, ultimately leading to lower costs in both labor and operational efficiency. By integrating slewing rings into these advanced systems, companies can achieve a streamlined workflow and minimize the need for extensive mechanical repairs.

Tip: Invest in operator training to ensure that the machinery, including slewing rings, is used effectively. Well-trained personnel can identify and address minor issues before they develop into major problems, saving time and resources.

Slewing rings play a critical role in enhancing safety within modern machinery, particularly in heavy equipment like cranes and excavators. Recent incidents, such as the cargo crane collapse at a Quebec port, highlight the importance of reliable componentry in ensuring operator protection. The failure of such equipment can lead to catastrophic accidents, emphasizing the need for robust design and continuous maintenance of machinery parts, including slewing rings. These components are engineered to provide better load distribution and stability, reducing the risk of equipment failure during operation.

Furthermore, advancements in slewing ring technology contribute to operator safety by integrating features that enhance situational awareness and mechanical reliability. Cutting-edge design improvements lead to increased performance and longevity, decreasing the likelihood of unexpected breakdowns. Machinery equipped with high-quality slewing rings can significantly mitigate risks during high-stakes tasks, thus creating a safer working environment for operators. As the construction and demolition industries continue to evolve, the role of these components becomes ever more vital, underscoring their importance in the ongoing pursuit of improved safety standards.

Slewing rings play a crucial role in the functionality of construction and mining equipment, serving as the pivotal component that allows for smooth rotational movement. In these industries, where precision and durability are paramount, slewing rings enable machinery like excavators, cranes, and drilling rigs to operate efficiently. Their design accommodates heavy loads while facilitating a wide range of motion, which is essential for tasks that require angular adjustments or positioning.

Additionally, the benefits of slewing rings extend beyond mere movement. They help improve the overall stability and safety of equipment by distributing loads evenly, reducing wear and tear on other machine parts. This reliability not only enhances operational efficiency but also prolongs the lifespan of the machinery.

As the global market for bearings is projected to grow significantly, the demand for robust slewing rings in construction and mining will likely increase, underscoring their vital role in advancing modern machinery solutions.