+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

When it comes to trucking needs, the right Dump Bed Cylinder can make all the difference. A reliable cylinder enhances the efficiency of your truck. It lifts heavy loads with ease. Choosing the best option for your tasks is crucial.

In 2026, several cylinders stand out in the market. Each one offers unique features that cater to different needs. Consider the weight capacity, durability, and price. Small details can significantly impact performance. For example, high-quality seals prevent leaks. Yet, some options may fall short in this regard.

Reflecting on experiences can guide your choice. Have you ever faced issues with your current cylinder? Identifying those problems can lead to better decisions. Upgrading might seem daunting due to costs. However, investing in the right Dump Bed Cylinder ensures long-term benefits.

Dump bed cylinders play a crucial role in the functionality of trucks used for hauling. They are responsible for lifting and tilting the bed, allowing for efficient unloading of materials. Without these cylinders, dumping heavy loads would be extremely challenging. Their importance cannot be overstated. They provide the necessary force to manage substantial weights, making them vital for construction and landscaping.

When selecting a dump bed cylinder, several factors come into play. The cylinder's size, stroke, and mounting style must match your truck's specifications. Perfect fitting is essential. An improper fit can lead to malfunction or damage. Additionally, the material of the cylinder impacts its durability and performance. Some users may overlook these details, leading to costly repairs.

Many truck operators often ignore maintenance until a problem arises. Regular checks and servicing can prevent issues. It's tempting to push limits, but this can backfire. The performance of your dump bed cylinder can directly impact productivity. A well-maintained cylinder enhances efficiency, while a neglected one creates delays. Ultimately, understanding these components and their upkeep is critical for optimal performance.

When selecting dump bed cylinders, understanding the types and their applications is crucial. Dump bed cylinders can be categorized into single-acting and double-acting designs. Single-acting cylinders utilize hydraulic pressure to lift the bed, relying on gravity for lowering. This makes them simpler and often more cost-effective. However, they may not provide the best control during dumping. On the other hand, double-acting cylinders allow for improved control. They provide power for both lifting and lowering, making them ideal for heavier loads.

Research indicates that the dump truck industry will grow at a CAGR of 4.2% from 2024 to 2029. This growth suggests increased demand for reliable dump bed cylinders. A good cylinder must handle the rigorous conditions in trucking. The material of construction significantly affects the durability and performance. Steel cylinders tend to be more robust, but they are heavier. Aluminum alternatives are lighter but may not support the same weight. It's a balancing act between weight and strength that requires careful consideration.

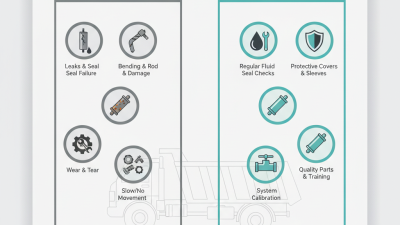

With the increasing need for efficiency, there are challenges. Not all cylinders are made equal. Some may wear out faster if they’re not suited for specific conditions. The installation process can also introduce flaws. If not properly calibrated, a cylinder may fail prematurely. Truck owners should reflect on their choices. It’s essential to weigh the benefits against potential long-term costs and maintenance requirements.

When selecting dump bed cylinders for trucking needs, several key features stand out. First, the material used in manufacturing can greatly impact performance. High-grade steel or aluminum alloys are commonly favored for their strength and durability. According to industry standards, cylinders made from these materials can withstand significant stress, enhancing their lifespan.

Additionally, the lifting capacity is critical. Most dump bed cylinders can handle loads ranging from 5,000 to 10,000 pounds. Properly matching the cylinder’s capacity with your hauling requirements can prevent potential failures. However, it's essential to consider that not all applications require the highest capacity. Over-specifying can lead to unnecessary costs and weight issues.

Maintenance requirements also vary. Some cylinders feature self-lubricating seals, which reduce upkeep. However, those that require regular lubrication may be more prone to wear over time. Data shows that maintenance issues account for up to 30% of cylinder failures. Evaluating features and understanding trade-offs is crucial for longevity and efficiency. It's a process that demands careful consideration and sometimes, a bit of trial and error.

When selecting the right dump bed cylinder for your trucking needs, understanding the options is crucial. Various types are available, including hydraulic and pneumatic cylinders. Each type serves different functions. Hydraulic cylinders are more common because they offer greater lifting power. They can support heavy loads and are efficient in dumping operations.

According to industry reports, over 60% of trucking companies faced issues related to cylinder performance. They noted that inadequate specifications led to operational inefficiencies. Many operators reported experiencing frequent maintenance problems, particularly with cheaper options. Understanding these pitfalls is essential. Inadequate cylinder size can lead to slower cycle times and, ultimately, lost revenue.

When choosing a dump bed cylinder, pay attention to the specifications. Look for materials that withstand harsh environments. Rust-resistant coatings are worth considering. It is also vital to match the cylinder with your truck’s capacity. For instance, a mismatch can drastically affect lifting performance and safety. The right choice not only enhances productivity but also prolongs the system's life. Always think critically about your needs and the potential drawbacks of your choices.

Maintaining dump bed cylinders is crucial for ensuring their longevity and optimal performance. Regular inspections can help identify wear and tear. Look for any signs of leaks or corrosion. A small issue can become a major problem if ignored. Keeping the cylinders clean is also essential. Dirt and debris buildup can hinder functionality.

Lubrication is another key aspect. Use the right type of grease to prevent rust and ensure smooth movement. However, over-greasing can lead to issues. Finding the right balance is important. It might take time to determine the ideal maintenance routine. Don't rush through these checks, as thoroughness is critical.

Sometimes, improper usage can cause damage. Consider the load weight and distribution before operating. Being mindful of how you use the dump bed can prevent costly repairs. Regular maintenance might take time, but the investment is worthwhile. Protecting your dump bed cylinders enhances performance and reliability.

| Cylinder Brand | Lift Capacity (lbs) | Cylinder Type | Material | Maintenance Tips |

|---|---|---|---|---|

| Hydraulic Plus | 8,000 | Double-acting | Steel | Regular oiling and checks for leaks |

| PowerLift | 10,000 | Single-acting | Aluminum | Inspect cylinder rods for wear |

| LiftMaster | 12,000 | Double-acting | Stainless Steel | Keep seals lubricated to prevent corrosion |

| DumpPro | 9,000 | Single-acting | High-Strength Steel | Check fluid levels regularly |

| CargoMax | 14,000 | Double-acting | Carbon Steel | Inspect and tighten connections periodically |