+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In the world of industrial machinery, the Hydraulic Cylinder Shaft plays a crucial role. It transfers force efficiently within hydraulic systems. Understanding different types of hydraulic cylinder shafts can greatly impact performance.

Various materials and designs exist, tailored for specific applications. Some are suited for high pressure, while others excel in durability. Yet, the choice can be daunting. Missteps may lead to inefficient performance. Observing the needs of your machinery is essential for success.

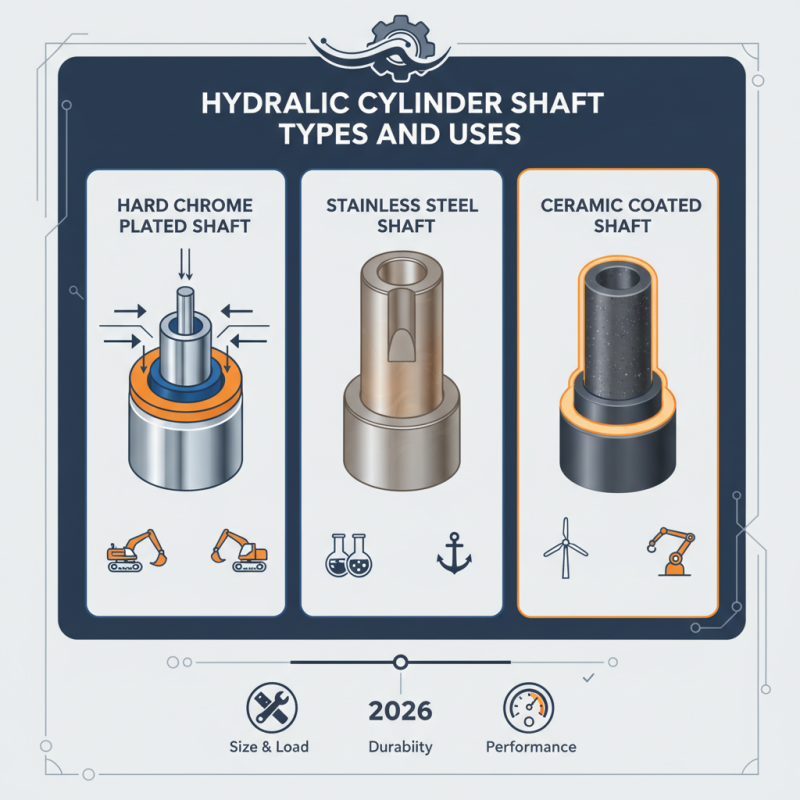

Consider the significance of size and load capacity. A poorly selected hydraulic cylinder shaft can cause failures. Ultimately, knowing your options and their uses enhances operations. This guide explores the best hydraulic cylinder shaft types in 2026.

Hydraulic cylinder shafts come in various designs and materials, each suited for specific applications. Common materials include steel, aluminum, and composite materials.

Steel shafts offer strength and durability, making them ideal for heavy-duty applications. Aluminum shafts, on the other hand, are lightweight and provide excellent corrosion resistance. According to industry reports, approximately 40% of hydraulic systems use steel shafts due to their resilience under high pressure.

One design aspect to consider is the shaft’s finish. Chrome-plated shafts are popular for their smooth surface, reducing friction and wear. However, this finish may not always be the best choice in certain environments. For example, in chemical industries, shafts made from specialized alloys might perform better. Mechanical engineers often face a dilemma here, weighing cost against performance.

Additionally, the size and diameter of the shaft are crucial. A standard size might fit most applications, but customization is increasingly common. Reportedly, about 30% of hydraulic systems now use custom-sized shafts. This reflects a growing awareness of efficiency and optimization. However, not all companies have the resources for such customization. Balancing precision engineering with budget constraints remains a challenge for many.

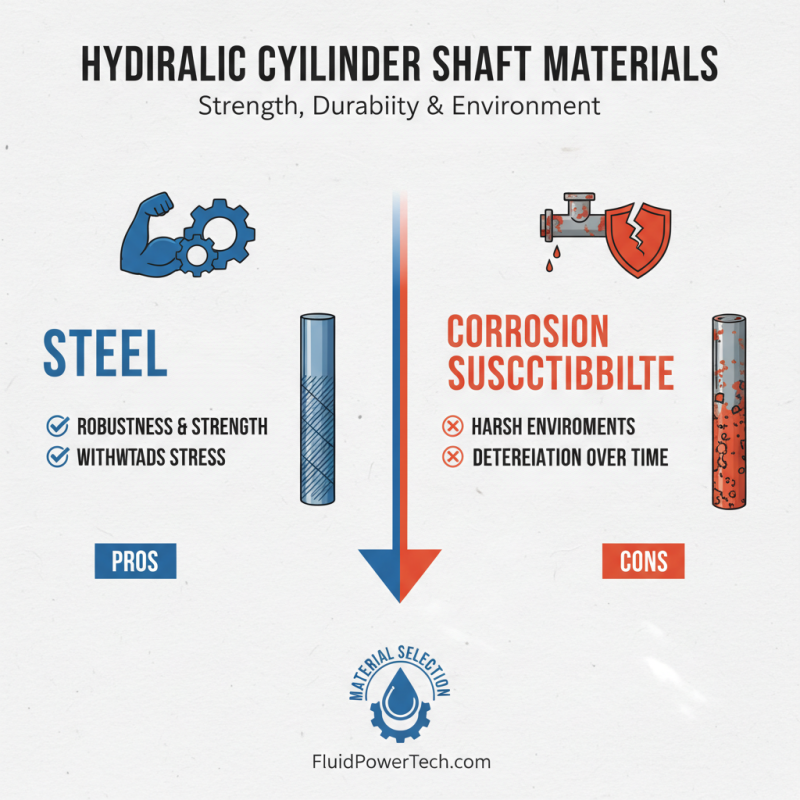

When selecting hydraulic cylinder shaft materials, it’s vital to consider strength and durability. Steel is commonly used due to its robustness. It can withstand significant stress under various conditions. However, it is also susceptible to corrosion. This can be a drawback in harsh environments.

Aluminum is another option. It is lighter than steel and offers good resistance to corrosion. This makes it ideal for mobile applications. However, aluminum might not endure high pressure as effectively as steel. Designers must weigh these factors carefully. Composite materials are gaining attention. They are lightweight and may offer enhanced corrosion resistance. Nonetheless, their long-term performance is still under scrutiny.

Often, performance varies based on the specific application. Improper selection can lead to premature wear or failure. Engineers need to assess load requirements and environmental factors. The choice of material directly influences the overall efficiency of the hydraulic system. Continuous testing and reevaluation are essential to ensure optimal performance.

Hydraulic cylinder shafts play a crucial role in many industries. They transfer force and motion, which is essential for various applications. In construction, these shafts support heavy machinery. They help lift and move massive loads, ensuring safety and efficiency on job sites. Without reliable hydraulic shafts, construction tasks would be slower and more dangerous.

In manufacturing, hydraulic cylinder shafts are used in assembly lines. They assist in operating presses and conveyors. These components enhance precision and speed in production processes. Quality hydraulic shafts lead to fewer breakdowns. Unfortunately, not all hydraulic shafts meet the necessary standards. This can result in costly downtimes and decreased productivity.

In agriculture, hydraulic cylinder shafts enable the operation of loaders and tillers. Farmers rely on them to plow fields and lift heavy equipment. Poor-quality shafts can hinder operations, requiring repairs or replacements. Damage can often go unnoticed until it's too late. Regular maintenance is essential to avoid these setbacks. Whether in construction, manufacturing, or agriculture, understanding the importance of hydraulic shafts is vital.

| Shaft Type | Material | Diameter Range (mm) | Typical Applications | Advantages |

|---|---|---|---|---|

| Hard Chrome Plated | Steel | 20 - 200 | Construction, Agricultural Equipment | Increased wear resistance, Low friction |

| Hollow Shaft | Aluminum | 25 - 150 | Robotics, Aerospace | Lightweight, Reduced material usage |

| Solid Shaft | Stainless Steel | 15 - 100 | Marine Applications, Food Processing | Corrosion resistant, High strength |

| Tapered Shaft | Carbon Steel | 30 - 120 | Automotive, Heavy Machinery | Ease of installation, Adjustable tension |

| Double Acting Shaft | Heat-Treated Steel | 40 - 250 | Industrial Equipment, Hydraulic Press | High strength, Versatile performance |

Hydraulic cylinder shafts are vital in various applications. Their performance is influenced by several factors. Material choice is crucial. Steel, aluminum, and composite materials provide different mechanical properties. Each material affects strength, weight, and resistance to corrosion.

Surface finish also plays a significant role. A smoother finish reduces friction and wear. A rough surface can cause premature failure. Proper coating can enhance durability, too. Regular maintenance helps identify wear early. This can prevent bigger issues down the line.

**Tips:** Always choose the right size for your application. A mismatch can lead to inefficiency or damage. Inspect the shaft regularly for signs of wear. Keep an eye out for any unusual sounds during operation. These simple checks can save time and money.

The future of hydraulic cylinder shaft technologies is promising. Innovations are emerging to improve efficiency and durability. For instance, advanced materials are being developed. These materials can withstand higher pressures and resist wear better than traditional options. This shift may lead to lighter designs that still offer robust performance.

Moreover, digital integration is becoming more common. Sensors embedded in shafts can monitor performance in real-time. This data can help in predictive maintenance. Detecting issues before they escalate could save time and resources. However, this technology is still in its infancy, and standardization is lacking.

While many advancements seem beneficial, challenges remain. The adoption of new materials often requires redesigning existing systems. Time and costs may hinder some companies from upgrading. Striking a balance between innovation and practicality is essential. As the industry evolves, these considerations will shape the future of hydraulic technology.