+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

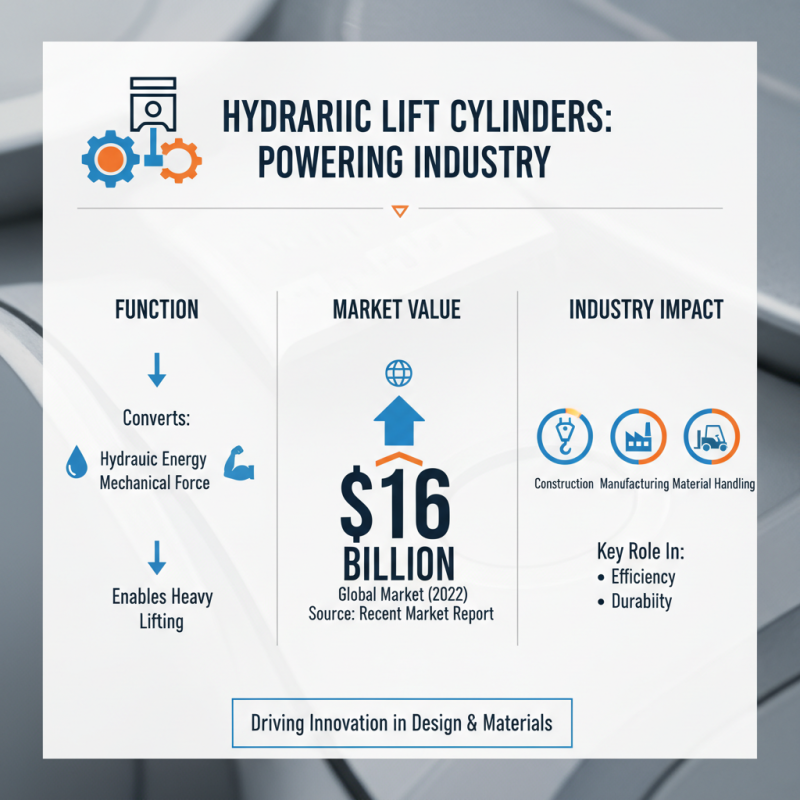

The efficiency and reliability of hydraulic lift cylinders are vital in various industries. According to a recent report by MarketWatch, the hydraulic cylinder market is expected to reach $16 billion by 2026. As industries evolve, the demand for high-quality hydraulic lift cylinders continues to rise. Expert John Miller, a leading analyst in hydraulic systems, emphasizes, "Choosing the right hydraulic lift cylinder is crucial for productivity and safety."

In a landscape filled with choices, selecting the best hydraulic lift cylinder model can be daunting. Each application has its unique requirements, from load capacity to stroke length. For instance, construction sites may need larger cylinders with robust lifting power, while manufacturing may require compact models for smaller spaces. This variety can lead to confusion, making it essential to research thoroughly and understand the specific needs of your operations.

Moreover, not all hydraulic lift cylinders are created equal. Quality can vary significantly among manufacturers. Poor choices can lead to equipment failure, risking both safety and financial loss. It’s important to reflect on past mistakes and learn from them. A well-informed decision on hydraulic lift cylinders can dramatically impact operational efficiency and overall success.

Hydraulic lift cylinders play a critical role in various industries, from construction to manufacturing. They convert hydraulic energy into mechanical force, making heavy lifting possible. According to a recent market report, the global hydraulic cylinder market was valued at approximately $16 billion in 2022. The demand for efficient and durable hydraulic lift cylinders is driving innovations in design and materials.

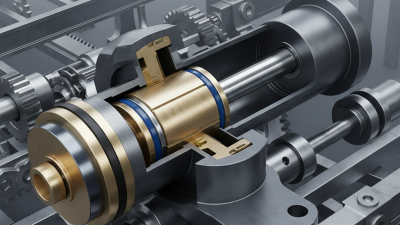

Understanding the mechanics behind hydraulic lift cylinders is essential for proper application. These cylinders utilize fluid pressure to create linear motion. They are typically constructed from high-strength materials to withstand significant stress. It’s crucial to consider the cylinder's size and force capacity to avoid mishaps. Inadequate pressure ratings can lead to cylinder failure and project delays.

However, choosing the right model poses challenges. Not all cylinders are suitable for every application. Some may not provide the required lift capacity. According to industry insights, around 30% of hydraulic failures stem from misapplication. Investing in quality and appropriately sized lift cylinders can prevent inefficiencies and high maintenance costs later. Understanding these elements can mitigate risks in high-stakes environments. It’s important to continually re-evaluate choices to align with evolving project needs.

When selecting hydraulic lift cylinders, several key features emerge as crucial for optimal performance and reliability. First, the cylinder's load capacity is paramount. A reputable industry report highlights that nearly 40% of failures stem from overload conditions. Thus, understanding the weight requirements and safety factors is essential. A mismatch can lead to significant downtime and costly repairs.

Another important consideration is the cylinder's bore size and stroke length. Bore size influences the force generated, while stroke length impacts the lift height. Industry standards recommend a bore size that balances efficiency and power. However, many users overlook these specifications, leading to undersized or oversized cylinders that fail to meet operational demands.

Seal quality also matters considerably. Poor seals can cause leaks, which may reduce efficiency by up to 20%. Regular maintenance and quality assessments should be part of the equipment lifecycle to prevent potential issues. Ignoring these details can diminish the overall effectiveness of the hydraulic system and lead to unexpected operational costs. Careful selection and attention to these features can enhance both lifespan and performance.

When choosing the best hydraulic lift cylinder models, understanding their specifications is crucial. The right model affects efficiency and safety. Industry reports indicate that over 70% of failures in hydraulic systems stem from improper cylinder selection. A detailed evaluation is essential.

Top-performing hydraulic lift cylinders often have a few key features. These include a robust build, precise tolerances, and reliable seals. Most operate efficiently under varying loads. A recent survey found that cylinders rated for 10,000 psi or higher offer the best durability and performance. However, quality does not always align with popularity. Some widely used models may lack innovative features, leaving room for improvement.

Many users report mixed experiences. Some cylinders function well initially but fail prematurely. A study noted that regular maintenance could extend their lifespan by up to 50%. Therefore, it’s vital to assess each hydraulic lift cylinder with a critical eye. Look for data that supports long-term performance. Reviews can sometimes exaggerate the effectiveness of specific models, leading to poor decisions.

Hydraulic lift cylinders are vital in multiple industries. They play crucial roles in construction, automotive, and manufacturing sectors. These cylinders can lift heavy loads with minimal effort. They create a linear motion that is efficient and reliable.

In construction, hydraulic cylinders are often used in excavators and cranes. They enable these machines to lift and move heavy materials. In the automotive industry, they assist in car lifts and jacks. The precision they offer is remarkable. However, there are rotating connections that may weaken over time. This can lead to unexpected failures. Regular inspections are key to maintain functionality.

Tips: Always check for leaks. Small leaks can lead to significant issues later. Be mindful of load limits. Exceeding them can damage the cylinder. In manufacturing, these cylinders facilitate operations like pressing and molding. Nonetheless, improper installation can cause operational hiccups. Careful installation is essential for long-term use.

| Model | Max Load Capacity (tons) | Stroke Length (inches) | Operating Pressure (psi) | Application |

|---|---|---|---|---|

| HLC-1000 | 10 | 12 | 3000 | Construction |

| HLC-1500 | 15 | 16 | 3500 | Manufacturing |

| HLC-2000 | 20 | 18 | 4000 | Agriculture |

| HLC-2500 | 25 | 20 | 4500 | Logistics |

| HLC-3000 | 30 | 24 | 5000 | Mining |

| HLC-3500 | 35 | 26 | 5500 | Heavy Industry |

| HLC-4000 | 40 | 30 | 6000 | Shipbuilding |

| HLC-4500 | 45 | 32 | 6500 | Renewable Energy |

| HLC-5000 | 50 | 35 | 7000 | Infrastructure |

Hydraulic lift cylinders are vital in various applications. Their durability directly impacts efficiency. Regular maintenance is crucial for longevity and reliability. According to industry reports, proper upkeep can extend cylinder life by up to 30%.

Check fluid levels frequently. Low hydraulic fluid often leads to overheating. This can cause significant damage and costly repairs. Moreover, always use the recommended fluid type. Incorrect fluids can degrade cylinder seals, leading to leaks and reduced performance.

Inspect seals and hoses for wear. Small cracks can escalate quickly. A minor leak can turn into a major issue if ignored. Replace any worn parts immediately. It’s a budget saver in the long run. Regular cleaning of the cylinder exterior also helps avoid damage from dirt and debris. It’s a simple yet effective practice.

Adopting these maintenance tips can significantly enhance the operation of hydraulic lift cylinders. While it requires effort, the return on investment in prolonged equipment life and reduced breakdowns is worth it.