+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right Wheel Lift Cylinder can be a daunting task. In 2026, industry experts stress the importance of making informed choices. John Smith, a renowned hydraulic systems engineer, says, "The performance of your Wheel Lift Cylinder can make or break your towing operations." His insight highlights the critical role these components play.

When selecting a Wheel Lift Cylinder, consider load capacity and compatibility. Many products claim to meet high standards but may fall short. Inspecting quality is a must. Some cylinders may also struggle with durability in harsh conditions. Feedback from real-world users is invaluable here.

The market is flooded with options, yet not all are created equal. Brands may advertise their cylinders as the best, but outcomes can vary. Reflect on your specific needs. Don't overlook maintenance aspects either. A costly cylinder may require frequent repairs, consuming your resources. Finding the ideal balance takes time and careful evaluation.

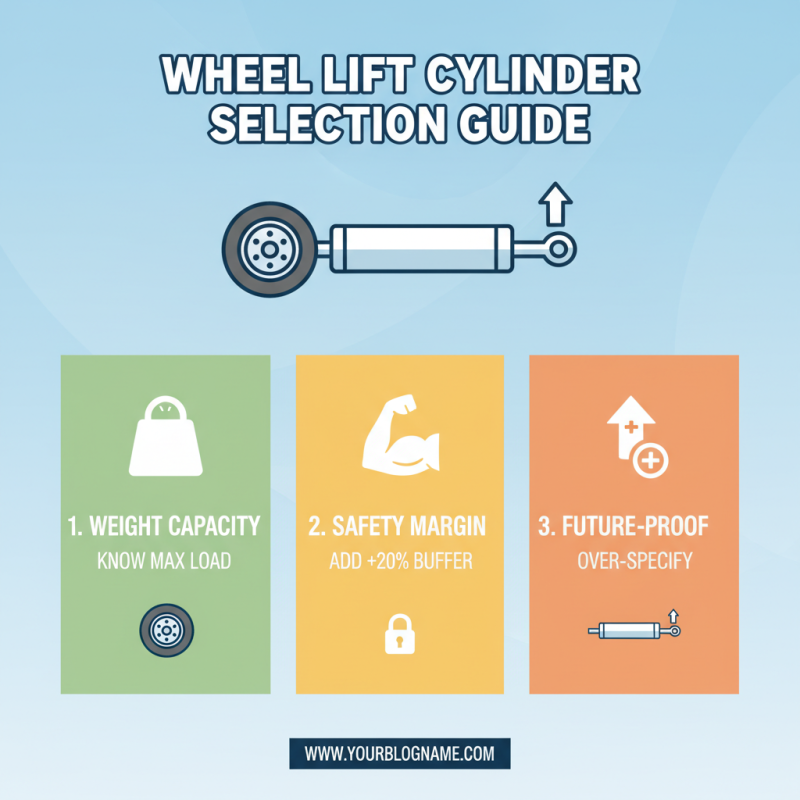

When choosing a wheel lift cylinder, consider several crucial factors. The cylinder's weight capacity is essential. You must know how much weight it can handle. Opt for a model that offers a bit more than you need. This ensures safety during operations.

Material plays a significant role. Steel is durable but may add weight. Aluminum is lighter but can be less robust. Assess the environment where you will use the cylinder. Will it face harsh conditions? If so, corrosion-resistant options are ideal.

Tips: Pay attention to dimensions. Too large or too small can be problematic. Always double-check compatibility with your wheel lift. Safety features are vital. Look for options with built-in safeguards.

Your budget is important but should not compromise safety. A cheaper cylinder may not perform well over time. Evaluate the reviews and seek feedback from users. This helps you understand real-world performance. Choose wisely to avoid facing regrets later.

When choosing between hydraulic and pneumatic wheel lift cylinders, consider various factors. Hydraulic systems are generally stronger. They provide a consistent lifting force. This makes them ideal for heavier vehicles. However, they can be more complex to maintain. Leaks in hydraulic fluid can occur. These leaks can lead to significant downtime.

On the other hand, pneumatic systems use compressed air. They are typically lighter and simpler. Installation can be quicker and easier. Yet, they may not lift as much weight as hydraulic types. Air pressure can fluctuate, impacting performance. A user might find this inconsistency frustrating. Each system has its own quirks that need addressing.

Reflecting on these points is essential. The choice isn't always clear-cut. One must weigh the benefits against potential drawbacks. Will the power of hydraulics outweigh the simplicity of pneumatics? Each application has unique needs. Understanding these details aids in making an informed decision. Ultimately, true evaluation comes from experience in the field.

| Type | Max Load Capacity (lbs) | Operating Pressure (psi) | Weight (lbs) | Price Range ($) |

|---|---|---|---|---|

| Hydraulic | 5000 | 2500 | 150 | 400-600 |

| Pneumatic | 3000 | 120 | 100 | 300-500 |

| Hydraulic | 7000 | 3000 | 160 | 500-700 |

| Pneumatic | 4000 | 100 | 90 | 250-400 |

When selecting a wheel lift cylinder, industry standards profoundly shape performance and safety. These standards establish the minimum requirements for operation under different conditions. Attention to these regulations is crucial, especially for users aiming for longevity and reliability in their equipment.

Manufacturers often reference safety ratings to ensure compliance. A cylinder’s load capacity is a key specification, indicating how much weight it can lift safely. It's essential to consider the type of hydraulic fluid used, too. The fluid might impact performance—some are better for cold weather, while others excel in hot conditions.

Users should be aware that not all wheel lift cylinders meet the same benchmarks. Variability in materials and design may lead to discrepancies in performance. Regular inspections can reveal underlying issues before they escalate. If inconsistencies arise, it may be time for a reassessment of safety practices and component choices. Staying informed about updates in industry standards helps in making better decisions.

When considering wheel lift cylinders, understanding the market landscape is essential. Many brands dominate this sector, each with unique strengths and weaknesses. Innovations in material and design have changed the game, but not all brands adapt equally. Some manufacturers focus on durability, offering products that can withstand tough environments. Others prioritize weight and ease of use, appealing to many users.

Market share among these brands shows a clear divide. A few companies hold significant portions, while others are gaining traction. Not every brand claims to be the best, and that humility is refreshing. It's crucial to evaluate customer feedback and performance metrics carefully. Some cylinders may excel in lifting capacity, but struggles with hydraulic efficiency can be a dealbreaker.

With new trends emerging, attention turns to how brands incorporate technology. Features such as automatic locking mechanisms and built-in safety systems enhance product functionality. However, these advancements must not compromise simpler designs that many users prefer. As the market evolves, it remains vital to weigh the pros and cons of each option before making a decision.

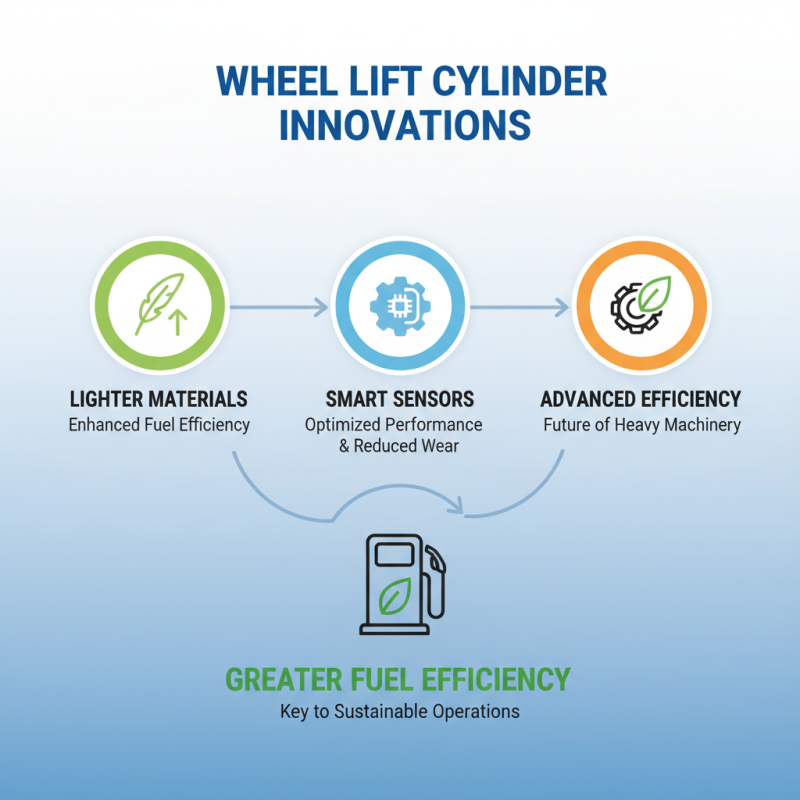

As wheel lift cylinder technology advances, efficiency is key. Future designs will focus on lighter materials. Integrating smart sensors can improve performance and reduce wear. These innovations may lead to greater fuel efficiency.

Tips: Consider materials that offer durability without adding weight. Look for cylinders with built-in monitoring systems. They can save maintenance costs in the long run.

Another trend is automation. Automated wheel lifts can enhance workflow. They are designed to reduce the physical strain on operators. This can lead to a safer working environment.

Tips: Research the control systems available. They should be intuitive and easy to operate. Safety features are critical; always prioritize them in your choice.

Design improvements are essential. Streamlined shapes can enhance aerodynamics. This aspect can lead to reduced energy consumption. Reflect on how design impacts overall efficiency. Each detail counts in maximizing performance.