+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In the evolving landscape of construction and heavy machinery, understanding the intricacies of bucket cylinders has become increasingly essential. Bucket cylinders, a critical component in various types of equipment, facilitate the smooth operation of excavators, loaders, and other machinery that rely on hydraulic systems. As we approach 2025, advancements in technology and engineering are set to enhance the performance and durability of these vital components, making it imperative for industry professionals to stay informed about their key features and benefits.

The significance of bucket cylinders extends beyond mere functionality; they contribute profoundly to the efficiency and safety of construction operations. With innovations such as improved hydraulic systems and enhanced materials, modern bucket cylinders are designed to withstand the rigors of demanding work environments while offering increased precision and control. This article aims to delve into the fundamental aspects of bucket cylinders, shedding light on how their evolution can translate to better productivity and reliability in the field.

As we explore the prominent characteristics and advantages of bucket cylinders, it is essential to consider their role in shaping the future of machinery and equipment used in construction. By focusing on these advancements, we can better understand their implications for operational efficiency, cost-effectiveness, and ultimately, the success of construction projects in the coming years.

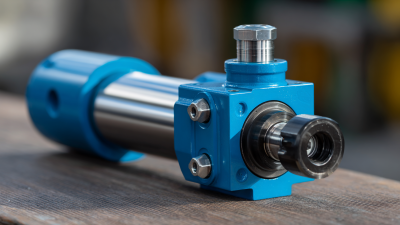

Bucket cylinders, often used in various industrial applications, feature several key components that enhance their functionality and applicability. At the core of a bucket cylinder are its robust seals and piston designs, which are crucial for maintaining hydraulic integrity and operational efficiency. According to a recent report from the International Fluid Power Society, effective seal systems can lead to a 20% increase in the lifespan of hydraulic cylinders, highlighting their importance in reducing maintenance costs and downtime.

Another significant component is the cylinder barrel, usually constructed from high-strength steel to withstand demanding environmental conditions. The durability of these materials is critical, as studies by the National Institute of Standards and Technology suggest that properly engineered bucket cylinders can support heavy loads while minimizing deformation under pressure. This performance is essential for industries such as construction and agriculture, where reliability and safety are paramount.

Lastly, the design of the rod and end fittings significantly influences the overall performance of bucket cylinders. Innovative designs can reduce friction and improve response times, contributing to more precise and efficient operations. The Fluid Power Journal notes that advancements in rod coating technologies can decrease wear by up to 30%, allowing for greater efficiency in applications that require frequent load changes. As we move towards 2025, these features will play an instrumental role in meeting the increasing demands for sustainability and efficiency in industrial processes.

This bar chart illustrates the key features and benefits of bucket cylinders based on projected data for 2025. The information is crucial for understanding how these components will enhance operational efficiency and performance in various industries.

Bucket cylinders have become increasingly popular in various modern applications due to their unique design and numerous advantages. One of the primary benefits of bucket cylinders is their ability to provide enhanced operational efficiency. By consolidating multiple functions into a single component, bucket cylinders reduce the need for additional hydraulic parts, ultimately minimizing system complexity. This leads to quicker installation processes and easier maintenance, saving both time and costs for operators.

Moreover, bucket cylinders offer significant space-saving advantages. Their compact design allows them to fit into tighter spaces where traditional cylinder configurations might be too large or cumbersome. This characteristic is particularly valuable in industries such as construction, agriculture, and material handling, where equipment must maneuver in constrained environments. Additionally, the increased lifting capacity and stability they provide enhance overall safety performance during operation. By ensuring a reliable grip on loads, bucket cylinders reduce the risk of accidents, further underscoring their appeal in modern applications.

The innovative design features of bucket cylinders for 2025 are poised to redefine their efficiency and versatility across various applications. At the forefront of these advancements is the integration of smart technology. Sensors embedded within the cylinders will monitor performance in real time, allowing for more precise control and adjustments based on the load and environmental conditions. This innovation not only enhances operational efficiency but also reduces wear and tear, ultimately extending the lifespan of the equipment.

Another key design feature is the enhanced lightweight materials used in the construction of bucket cylinders. These materials provide increased strength while significantly reducing the overall weight of the cylinders. This weight reduction translates to improved fuel efficiency in machinery and easier maneuverability, particularly in challenging terrains. Additionally, the adoption of ergonomic designs in the handles and operating mechanisms ensures that user comfort is prioritized, promoting safer and more effective operation for workers in the field. Collectively, these features reflect a shift towards more sustainable and user-friendly solutions in the construction and heavy machinery industries.

To ensure optimal performance of bucket cylinders, regular maintenance is crucial. Start by regularly inspecting the cylinders for any signs of wear or damage. Look for leaks, cracks, or deformation, as these can lead to decreased efficiency and potentially hazardous situations. Keeping a checklist for routine inspections can help you stay on top of any emerging issues before they escalate.

In addition to visual inspections, lubrication plays a significant role in maintaining bucket cylinders. Proper lubrication minimizes friction and wear on moving parts, extending the lifespan of the equipment. Make sure to use the recommended lubricant and apply it according to the manufacturer's specifications. Similarly, check the seals and gaskets for integrity, as they are pivotal in preventing leaks and ensuring consistent performance.

Another important maintenance tip is to keep the cylinders clean and free from debris. Dirt or contaminants can lead to premature failure and hinder the smooth operation of the cylinders. Regularly cleaning the exterior and ensuring that no foreign materials interfere with the moving parts is essential. By adopting these routine maintenance practices, operators can enhance the reliability and efficiency of bucket cylinders, ensuring they remain in top condition throughout their usage.

The bucket cylinder technology has evolved significantly and is set to undergo further advancements by 2025. This evolution is driven by the need for increased efficiency and safety in various industries, including construction and agriculture. Future trends indicate a shift towards smart technology integration, where sensors will monitor performance and alert operators to potential issues in real time. This proactive approach not only enhances operational efficiency but also prolongs the lifespan of the equipment.

Tips for maximizing the effectiveness of bucket cylinders include regularly scheduled maintenance and adopting new technologies as they become available. Ensuring that operators are trained on the latest features can enhance productivity and safety. Additionally, utilizing automation where possible can reduce manual labor and minimize risks associated with operator fatigue.

Moreover, the push towards sustainability is expected to influence bucket cylinder designs. We may see an increase in the use of eco-friendly materials and energy-efficient systems. These trends will not only help reduce the carbon footprint but also appeal to environmentally conscious businesses looking to invest in greener technologies. Keeping an eye on these developments can position companies to adapt quickly and maintain a competitive edge in the marketplace.

| Feature | Description | Benefits | Future Trends |

|---|---|---|---|

| Material Composition | High-strength alloys and composites | Increased durability and reduced weight | Adoption of sustainable materials |

| Hydraulic Efficiency | Enhanced design for fluid dynamics | Improved response time and power output | Integration with smart hydraulic systems |

| Customizability | Modular designs for specific applications | Tailored solutions for unique operational needs | Increased demand for specialized equipment |

| Automation Compatibility | Support for robotic and automated systems | Enhanced productivity and reduced labor costs | Growing trends in autonomous operations |

| Safety Features | Integrated sensors and failsafe mechanisms | Enhanced operator safety and reduced accidents | Regulatory compliance and industry standards |