+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Bucket cylinders play a pivotal role in the efficient functioning of various industrial applications, ranging from construction to agricultural machinery. As the global construction industry is projected to reach a market size of over $10 trillion by 2023, the demand for reliable and robust hydraulic components, such as bucket cylinders, has seen a significant increase. These cylinders are essential for enabling the movement and control of heavy loads, making them an integral component in excavators, backhoes, and loaders.

According to a recent market analysis report by Research and Markets, the hydraulic cylinder market is expected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next five years. This growth is driven by advancements in technology and the increasing demand for automation in manufacturing and construction processes. Furthermore, the versatility of bucket cylinders in various applications, from lifting and digging to compacting and conveying, underscores their importance across multiple sectors including mining, forestry, and waste management. As industries continue to evolve and embrace more demanding operational requirements, understanding the types and applications of bucket cylinders becomes crucial for optimizing performance and enhancing productivity.

Bucket cylinders, an essential component in a variety of industrial applications, come in several types, each designed to serve specific needs. One of the most common types is the single-acting bucket cylinder, which operates by directing hydraulic fluid to one side of the piston, enabling it to lift loads effectively. These cylinders are often used in applications requiring straightforward lifting capabilities, such as in construction and material handling, where the force generated on one side suffices to complete the task.

Another notable type is the double-acting bucket cylinder, which allows for movement in both directions by applying hydraulic pressure on both sides of the piston. This design provides greater control and efficiency, making it ideal for operations like excavation and excavation machinery where precise positioning and retraction are critical.

Additionally, specialized configurations such as telescopic bucket cylinders offer enhanced reach and versatility, catering to industries like mining and agriculture where access to difficult-to-reach areas is necessary. Each type of bucket cylinder boasts unique features that cater to various operational requirements, making them indispensable tools across multiple sectors.

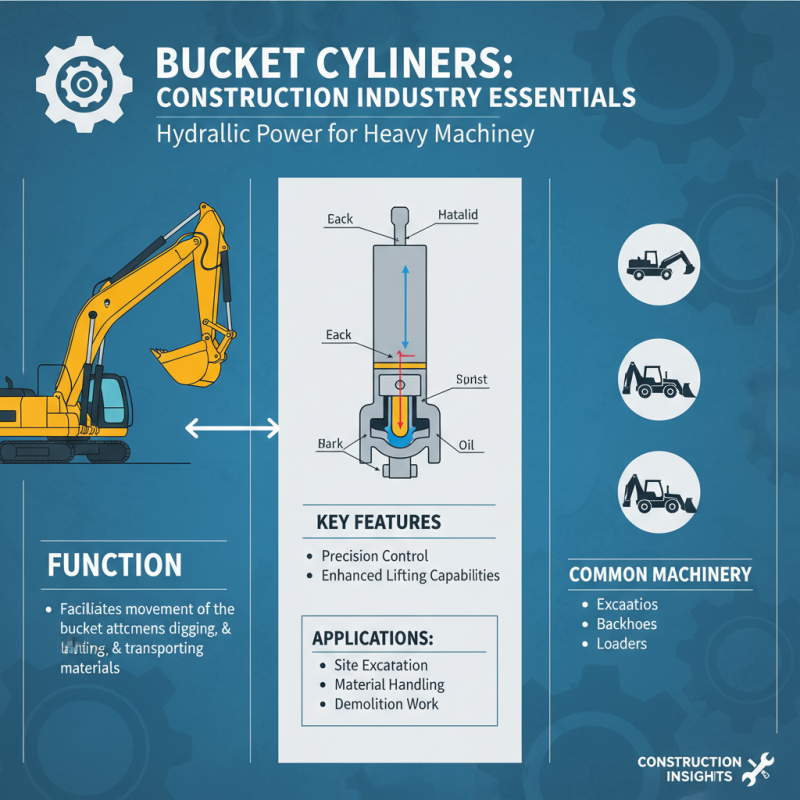

Bucket cylinders, often employed in the construction industry, are essential components in various heavy machinery. These hydraulic cylinders facilitate the movement of bucket attachments used in excavators, backhoes, and loaders, making them instrumental in digging, lifting, and transporting materials. The design of bucket cylinders allows for precise control and enhanced lifting capabilities, which are critical for tasks such as site excavation, material handling, and demolition work.

In construction sites, the versatility of bucket cylinders allows operators to adapt to different conditions and requirements. For instance, they can be equipped with various bucket sizes and shapes, which enables efficient handling of diverse materials ranging from soil and gravel to debris from demolition activities. Additionally, bucket cylinders enhance the safety and efficiency of operations by enabling operators to lift heavy loads with minimal physical strain and optimal stability. Their reliability and performance under challenging conditions make them a valuable asset in streamlining construction processes and improving productivity.

Bucket cylinders play a crucial role in the waste management industry, where efficiency and reliability are paramount. These hydraulic cylinders are specifically designed to manipulate large buckets, enabling the loading, lifting, and unloading of heavy waste materials. Their robust construction allows them to withstand harsh conditions, making them ideal for use in landfills and recycling facilities. By effectively managing the movement of waste, bucket cylinders enhance operational efficiency and reduce the need for manual labor, thereby optimizing resource allocation.

When utilizing bucket cylinders in waste management, consider the following tips for improved performance and safety. First, regular maintenance is essential; ensure that all hydraulic components are checked for leaks and proper lubrication to prevent unexpected downtime. Additionally, operators should undergo training to understand the specific capabilities and limitations of the equipment, as this knowledge can prevent accidents and improve overall efficiency. Lastly, adopting technology such as load sensors can help prevent overloading, thus protecting both the machinery and the workforce involved in waste operations.

These practices contribute to a more streamlined waste management process, reflecting the growing need for sustainable solutions across various industries. As the world increasingly prioritizes environmental responsibility, the effective use of bucket cylinders will become even more critical in managing waste efficiently and safely.

Bucket cylinders play a crucial role in agricultural equipment, providing the necessary force and precision for various tasks such as lifting, tilting, and loading. In an industry that relies heavily on efficient machinery, the importance of these hydraulic components cannot be overstated. According to a report by Milling & Grain, the agricultural sector is expected to expand significantly, with a projected growth rate of 4.1% annually over the next five years. This growth will drive demand for advanced agricultural equipment, including those utilizing bucket cylinders for functions like tilling, planting, and harvesting.

In practical applications, bucket cylinders are employed in tractors and loaders to enhance their operational efficiency. Their ability to handle heavy loads with minimal effort makes them indispensable in modern farming operations. A study by the American Society of Agricultural and Biological Engineers found that the incorporation of hydraulic systems in agricultural machinery can improve productivity by up to 25%. Moreover, with the increasing adoption of precision farming techniques, the role of bucket cylinders in ensuring accurate and effective machinery operation is becoming ever more critical, allowing farmers to optimize yields while minimizing resource use.

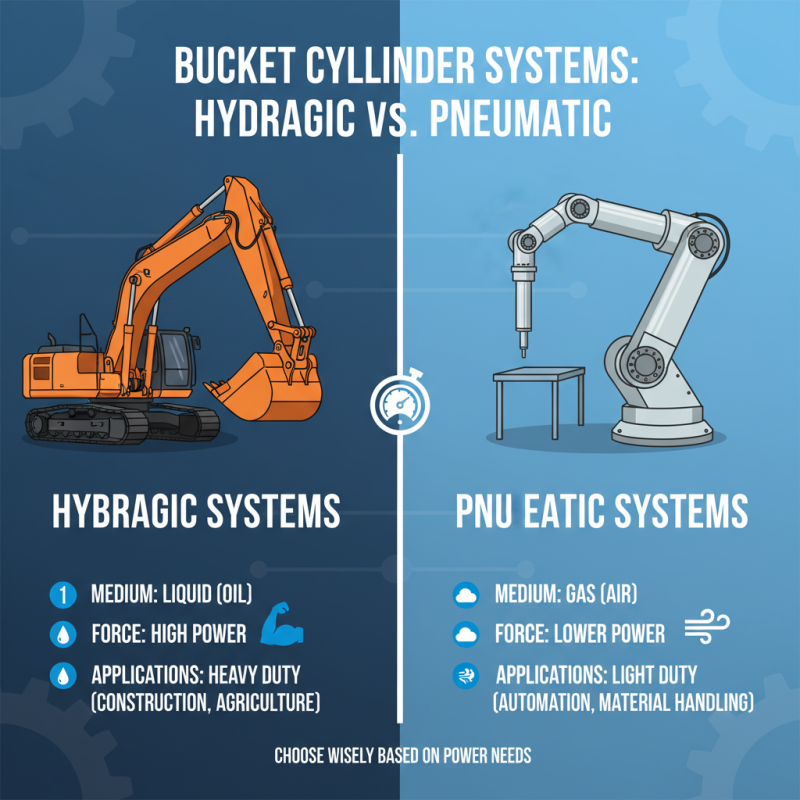

When examining bucket cylinders, one crucial aspect to consider is the comparison between hydraulic and pneumatic systems. Hydraulic bucket cylinders utilize liquid under pressure to generate force, making them ideal for heavy-duty applications. They provide significant lifting capacity and precise control, making them suitable for tasks in construction, agriculture, and manufacturing. The strength of hydraulics lies in their ability to handle substantial loads with minimal effort, making them a preferred choice for operations requiring high power.

In contrast, pneumatic bucket cylinders operate using compressed air, which allows for faster motion and lighter weight. These cylinders are often used in applications where speed is essential over raw lifting power. Industries such as packaging and assembly lines frequently rely on pneumatics for quick actuation and responsiveness. Although they may not match the load capabilities of hydraulic systems, their maintenance and operational costs are generally lower, making them an attractive option for lighter tasks.

Tips: When selecting between hydraulic and pneumatic bucket cylinders, evaluate the specific requirements of your application, including load capacity, speed, and maintenance capabilities. Understanding these factors can help ensure efficient operation and cost-effective solutions tailored to your industry needs. Additionally, consider the environment where the cylinders will operate, as exposure to extreme temperatures or harsh conditions may influence your choice of system.