+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right Bucket Cylinder can seem daunting. Many factors influence this decision. Understanding your specific application is crucial.

Bucket Cylinders come in various sizes and styles. Each type serves a different purpose. A mismatch can lead to inefficiency or damage. Assess the weight and reach needed for your tasks. Think about the environment where it will be used.

Failure to select the appropriate Bucket Cylinder may have consequences. It may result in escalating costs or downtime. It’s essential to weigh the options carefully. Inadequate research can lead to regret later. Overall, careful consideration is key to making an informed choice.

Bucket cylinders play a crucial role in various applications, particularly in construction and material handling. They are designed to provide efficient lifting and lowering of heavy loads. Understanding their basic functions is key to choosing the right model for specific needs. According to industry data, about 70% of equipment malfunctions originate from the incorrect selection of hydraulic components, including bucket cylinders.

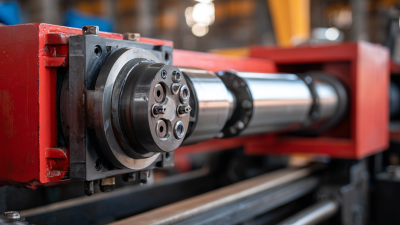

The primary function of a bucket cylinder is to convert hydraulic pressure into mechanical force. This mechanics is essential for tasks like digging or moving materials. When selecting a bucket cylinder, factors like stroke length, bore size, and pressure ratings must be considered. Reports indicate that a mismatch in these specifications can lead to reduced efficiency and premature equipment failure.

Maintenance is another critical aspect. Regular inspections can help identify wear and tear. Ignoring these checks may result in downtime and increased costs. Industry analytics suggest that businesses could save up to 30% on operational costs through proactive maintenance strategies. Recognizing these dynamics aids in making informed decisions regarding the use of bucket cylinders in any operational setup.

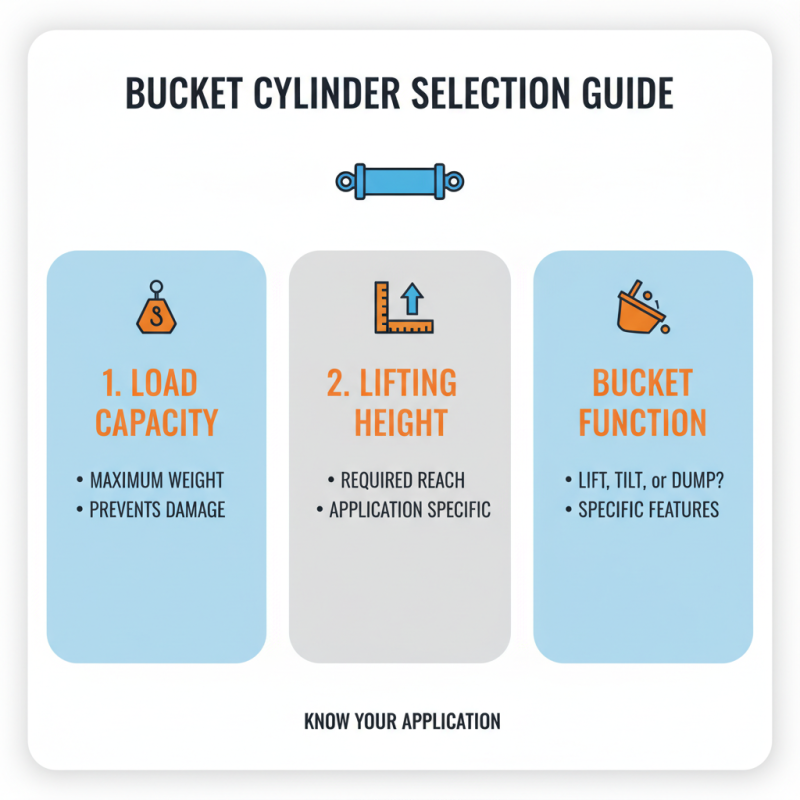

When selecting a bucket cylinder, understanding your application requirements is key. Start by considering the load capacity. Know the maximum weight your equipment will handle. This helps prevent potential damage. Evaluate the lifting height needed. Different applications require different heights. Assess how you will use the bucket. Will it lift, tilt, or dump? Each function may require specific features.

Tips: Always check the hydraulic pressure ratings. This can influence performance. Also, consider the environment where the bucket cylinder will operate. Extreme temperatures or corrosive conditions can affect durability.

Next, think about cycle times. High-frequency usage needs a cylinder that can handle rapid operations. Reflect on how often you will operate it. A cylinder that’s too slow might hinder your work efficiency. Additionally, review the available space for installation. Limited space can restrict your cylinder choices. Take meticulous measurements before selecting a model.

In some cases, you might need to adjust specifications based on real-world experiences. Testing different models can provide better insights. Continuous improvement based on operational feedback is vital for optimal performance.

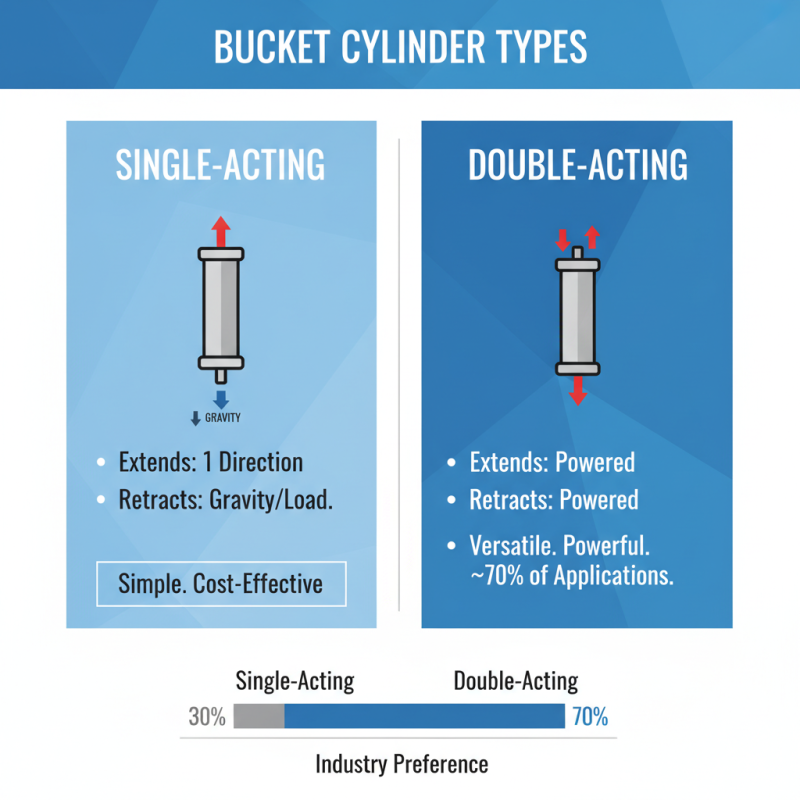

When selecting a bucket cylinder, understanding the various types is essential. There are single-acting and double-acting bucket cylinders. Single-acting cylinders extend in one direction, using gravity for retraction. This design is simple and cost-effective but may not be suitable for all applications. In contrast, double-acting cylinders are versatile and provide power in both directions. According to industry reports, around 70% of applications benefit from double-acting configurations due to their efficiency.

Material and size also play critical roles. Steel cylinders offer durability and resistance to wear, while aluminum models are lighter and less costly. For instance, a recent analysis revealed that using aluminum can reduce operational costs by up to 20% in specific applications. However, aluminum may not withstand harsh conditions, leading to more frequent replacements. This presents a dilemma: should a company prioritize cost savings or long-term durability?

Installation factors must not be overlooked. A poorly fitted cylinder can result in leaks and inefficiencies. Research has shown that improper installation can reduce efficiency by as much as 15%. Thus, evaluating all aspects is crucial. Many users overlook this detail, leading to unforeseen barriers in performance. The choice of a bucket cylinder is more complex than it seems. Each decision carries weight and must align with specific operational needs.

Selecting the right bucket cylinder is crucial for optimal performance in various applications. The key factors include load capacity, stroke length, and mounting options. According to industry reports, nearly 40% of hydraulic failures stem from incorrect cylinder specifications. Thus, understanding your specific needs is essential.

Load capacity shapes the type of cylinder you need. A mismatch can lead to early wear or catastrophic failure. For instance, if your application requires lifting 10 tons, but the cylinder can only handle 8 tons, it won't perform. This discrepancy can cost companies thousands in repairs and downtime. Cylinder stroke length also significantly impacts functionality. Too short or too long can limit efficiency.

Additionally, consider mounting configurations. Inspect how the cylinder will be integrated into existing systems. Improper installation can reduce productivity. A recent survey indicated that 25% of mechanics encountered issues stemming from poor mounting choices. Always double-check the mounting type to avoid costly mistakes. Thoughtful consideration of these factors is not just beneficial; it’s essential for operational success.

Choosing the right bucket cylinder is crucial for optimal performance. Many users overlook essential factors. One common mistake is failing to calculate the required force accurately. Without proper calculations, the cylinder may underperform or fail to meet your application's demands.

Another mistake is ignoring the environment in which the cylinder operates. Factors like temperature, humidity, and exposure to chemicals can significantly affect the cylinder's effectiveness and lifespan. Selecting a cylinder that isn’t designed for such conditions can lead to unexpected issues down the line.

Lastly, disregarding maintenance requirements is a frequent oversight. Every bucket cylinder has specific needs for upkeep. Neglecting regular checks can result in premature wear or failure. Take the time to research and understand these aspects before making your choice. This research can save you from costly mistakes in the long run.

| Dimension | Specification | Common Mistakes | Recommendations |

|---|---|---|---|

| Bore Diameter | 2.5 - 6 inches | Choosing too small a bore size | Evaluate the lifting capacity required |

| Stroke Length | 12 - 72 inches | Underestimating stroke requirements | Ensure the stroke allows full operation range |

| Pressure Rating | 2000 - 5000 PSI | Ignoring pressure limits | Match with system pressure |

| Mounting Style | Pin, Eye, Clevis | Selecting the wrong mounting type | Assure compatible mounting with equipment |

| Seal Type | Standard, High Performance | Neglecting seal compatibility | Choose seals based on environment and application |