+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right Loader Lift Cylinder is crucial for ensuring optimal performance and efficiency in various equipment applications. The Loader Lift Cylinder plays a pivotal role in the operation of loaders by providing the necessary force to lift and maneuver heavy loads. As a fundamental component of construction, agricultural, and industrial machinery, selecting the appropriate cylinder can significantly impact the overall productivity and safety of your operations.

When considering which Loader Lift Cylinder to use, it is essential to evaluate various factors such as load capacity, compatibility with existing equipment, and environmental conditions. Each application presents unique challenges that can affect the performance of the lift cylinder, making it imperative for operators and decision-makers to carefully assess their specific equipment needs. By understanding these aspects, users can make informed choices that not only enhance operational efficiency but also extend the lifespan of their machinery. In this guide, we will explore key considerations and best practices for selecting the right Loader Lift Cylinder to meet your equipment demands effectively.

Loader lift cylinders are crucial components that significantly influence the performance and efficiency of heavy equipment. These hydraulic cylinders function as the driving force behind the lifting mechanism, enabling loaders to raise and lower their attachments with speed and precision. When selecting the right loader lift cylinder, factors such as size, capacity, and stroke length must be considered, as they directly affect how well the equipment can handle various loads and conditions. An appropriately chosen lift cylinder can enhance operational speed and reduce cycle times, ensuring that the equipment operates at peak performance.

Moreover, the efficiency of loader lift cylinders also impacts overall fuel consumption and wear on the machine. A hydraulic cylinder that is well-matched to the loader's specifications can optimize hydraulic fluid usage, resulting in less energy expenditure. This efficiency not only prolongs the lifespan of the equipment by minimizing strain on its hydraulic system, but it also contributes to lower operational costs over time. Therefore, understanding the relationship between loader lift cylinders and equipment functionality is essential for achieving optimal results in any heavy lifting operations. Proper selection and maintenance of these cylinders lead to enhanced productivity and reliability in demanding work environments.

When selecting loader lift cylinders, understanding key specifications is essential to ensure compatibility with your equipment’s operational requirements. One of the most critical factors is the cylinder's bore size, which can influence the lifting capacity significantly. According to a report by the Equipment Manufacturers Association, a larger bore size typically results in a higher lifting force—an essential consideration for heavy-duty applications. The bore size must align with the pressure rating of your hydraulic system; for instance, cylinders rated for a higher pressure allow for increased engagement with larger loaders, which can lift heavier loads efficiently.

Another important specification is stroke length, directly affecting the range of motion of your loader. Industry data indicates that selecting the appropriate stroke length can improve performance and operational efficiency. For example, a longer stroke can facilitate greater lift heights and increased flexibility in various working conditions, making it suited for construction or agricultural applications.

Additionally, the sealing mechanism and overall cylinder design play pivotal roles in durability and safety; multipurpose cylinders are often recommended for environments where contamination is a risk, as they enhance lifespan and reduce maintenance costs. Properly assessing these specifications ensures that the loader lift cylinder selected not only meets performance expectations but also aligns with the safety standards required for efficient operation.

When selecting the right loader lift cylinder, understanding load capacity ratings is crucial for ensuring optimal performance and safety. Load capacity, typically measured in pounds or tons, defines the maximum weight the lift cylinder can effectively handle.

According to data from the Equipment Manufacturers Association (EMA), common loader lift cylinders have loading capacities that can range from 5,000 to over 20,000 pounds depending on the application. This range emphasizes the importance of matching the cylinder’s capacity with the specific needs of your equipment.

In addition to the nominal load capacity, it's essential to consider factors such as dynamic loading conditions and potential impacts. Research indicates that lift cylinders can experience loads exceeding their capacity during certain operations, such as lifting on uneven ground or handling off-center loads.

The Hydraulic Institute suggests that operators should always incorporate a safety factor, typically 1.5 to 2 times the expected load, into their calculations. This ensures that even in challenging conditions, the cylinder will operate efficiently without risk of failure. Understanding these parameters can guide equipment managers in making informed choices, thereby prolonging the lifespan of their loaders and enhancing workplace safety.

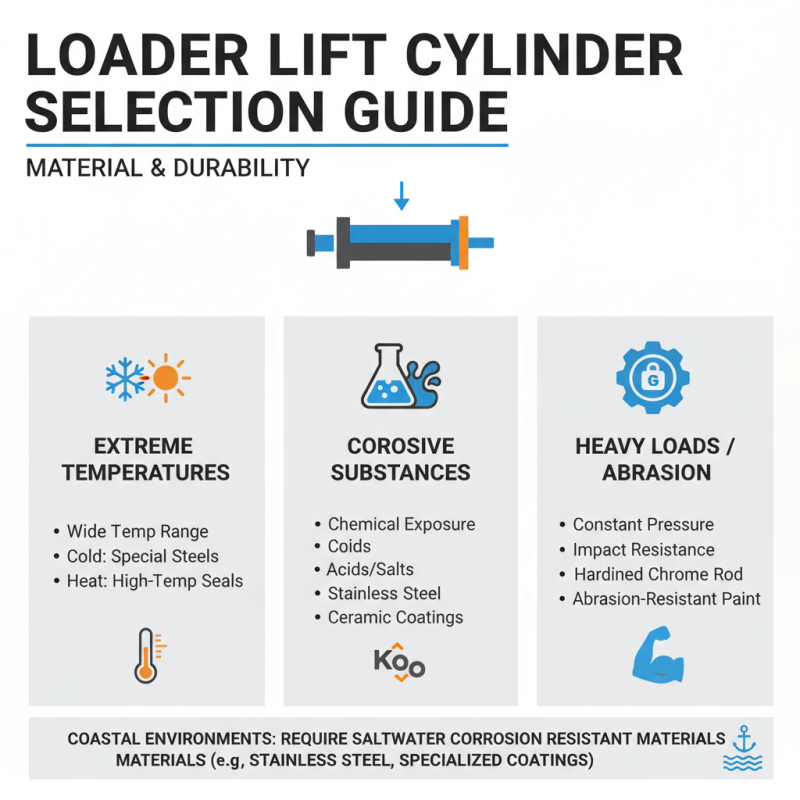

When selecting a loader lift cylinder, one of the foremost considerations is the material and durability required for the specific environment in which your equipment will operate. Different applications may expose cylinders to various conditions such as extreme temperatures, corrosive substances, or heavy loads. For instance, if the cylinder will be used in a coastal area, materials that resist saltwater corrosion, such as stainless steel or specialized coatings, are essential to prolong the lifespan of the equipment and minimize maintenance costs.

In addition to environmental factors, the expected load capacity and frequency of use should also dictate the material selection. High-strength alloys might be necessary for heavy-duty applications, whereas lighter materials could suffice for less strenuous tasks. Furthermore, it’s vital to consider the impact of wear and tear; cylinders should be chosen based on their resistance to abrasion and fatigue. By carefully assessing the operating conditions and selecting the appropriate materials, users can ensure that their loader lift cylinders perform optimally and endure the rigors of their specific applications.

When it comes to selecting the right loader lift cylinder for your equipment, the balance between cost and quality plays a crucial role in ensuring optimal performance. According to a report by the National Association of Manufacturers, approximately 79% of equipment failures are attributed to poor quality components. Thus, investing in high-quality loader cylinders not only minimizes downtime but also enhances the lifespan of your machinery.

While initial costs can be a deciding factor for many operators, a closer examination reveals that the long-term savings from avoiding frequent replacements of subpar cylinders can outweigh these upfront expenses. Industry analysis indicates that a well-constructed loader lift cylinder can result in a 20-30% decrease in maintenance costs over a five-year period, as noted by several manufacturing studies. Therefore, it's essential to assess the specifications and construction materials of loader cylinders, ensuring they meet the demands of your specific applications while also being cost-effective over time. Prioritizing quality can lead to improved reliability and, ultimately, a better return on investment in the future.