+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In today's fast-paced industrial landscape, the demand for efficient and space-saving solutions has led to the increased usage of Compact Hydraulic Cylinders. These hydraulic components are crucial in applications where space is at a premium, such as in construction machinery, robotics, and automation systems. According to a report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach USD 12.2 billion by 2025, with a significant portion attributed to the growing need for compact designs that enhance operational efficiency while minimizing overall machinery footprint.

Selecting the right Compact Hydraulic Cylinder is essential for optimizing performance in various applications. Factors such as load capacity, stroke length, mounting options, and operating conditions need to be carefully considered to ensure reliability and effectiveness. As the industry continues to innovate, advancements in materials and design technology further enhance the functionality and adaptability of these cylinders, enabling them to meet the specific requirements of diverse sectors.

Ultimately, making an informed choice about Compact Hydraulic Cylinders can significantly impact productivity and maintenance costs. As organizations seek to increase their competitive edge, understanding the intricacies involved in selecting the right hydraulic solution is more critical than ever, marking a step towards achieving superior operational excellence.

Compact hydraulic cylinders are essential components in various industries, offering space-saving solutions without compromising on performance. These cylinders are designed for applications where installation space is limited but power and precision are still required. According to a report by the International Fluid Power Society, compact hydraulic cylinders can provide a force output typically ranging from 1000 to 4000 pounds, making them suitable for tasks requiring both strength and agility, such as robotics, material handling, and industrial machinery.

Understanding the specific applications for which compact hydraulic cylinders are intended is crucial for selecting the right type. In manufacturing settings, for example, they are often utilized in automated assembly lines, where quick actuation and reliable performance are paramount. The American Society of Mechanical Engineers states that the demand for compact hydraulic solutions is projected to grow by approximately 6% annually, driven by innovation in automation technologies and the need for more efficient machinery. Thus, when choosing a cylindrical unit, it's vital to consider factors such as stroke length, mounting style, and pressure ratings to ensure optimal functionality in your particular application.

| Application | Cylinder Type | Bore Size (inches) | Stroke Length (inches) | Max Pressure (psi) |

|---|---|---|---|---|

| Material Handling | Double-Acting | 2.0 | 12 | 2500 |

| Construction Equipment | Single-Acting | 3.0 | 18 | 3000 |

| Automotive Testing | Double-Acting | 1.5 | 10 | 2000 |

| Aerospace Applications | Compact | 2.5 | 8 | 4000 |

| Robotics | Miniature | 1.0 | 5 | 1500 |

When choosing the right compact hydraulic cylinder for your applications, several key factors should be taken into consideration to ensure optimal performance and reliability. First, the pressure rating is crucial; most compact hydraulic cylinders are designed to operate in a range of 1500 to 6000 psi, depending on the application. Matching the cylinder's pressure capacity with the requirements of your system is essential to avoid premature failure. Additionally, understanding the force output is vital. According to industry studies, the force generated by a hydraulic cylinder is determined by the cylinder's diameter and the operating pressure. A thorough analysis of these parameters can guide you in selecting the cylinder that meets your specific needs.

Another critical factor is the stroke length, which directly impacts the cycle time and efficiency of your operation. While many compact cylinders offer a stroke length ranging from 1 inch to 12 inches, calculating the necessary stroke for your application will help streamline processes. Furthermore, the mounting style and configuration—whether it’s a through-hole, rear, or side-mounted type—should align with your machine's layout to ensure proper installation and functionality. Recent surveys in the hydraulic industry show that nearly 70% of users report improved performance when the right mounting configuration is employed, highlighting the importance of this selection aspect.

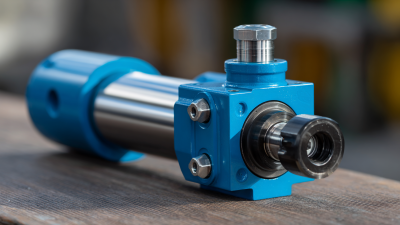

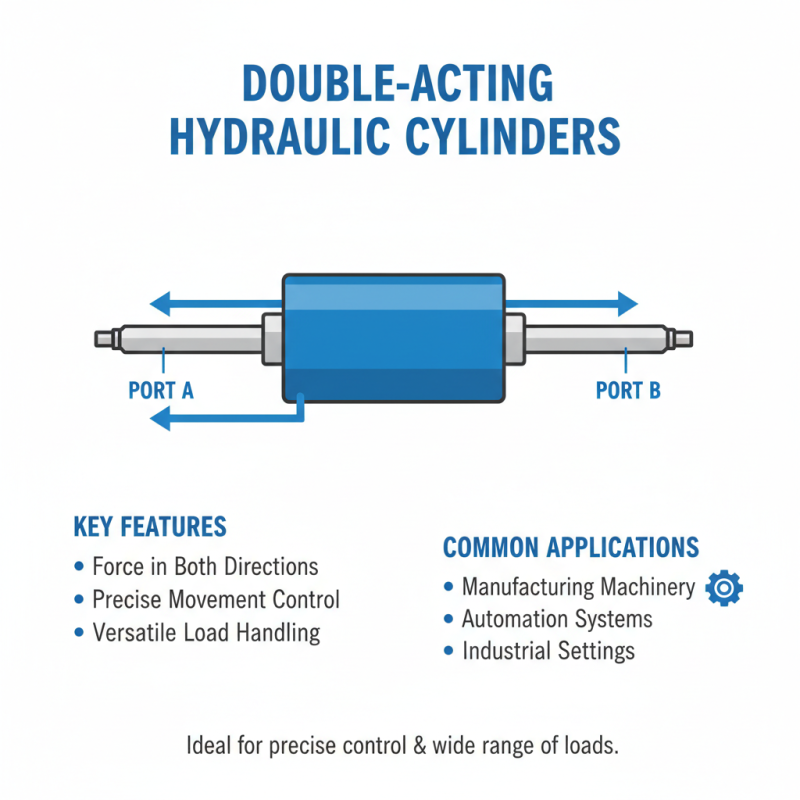

When selecting a compact hydraulic cylinder, it's crucial to understand the various types available and their specific applications. One common type is the double-acting cylinder, which is designed to exert force in both directions. This makes it ideal for applications requiring precise control over movement, such as in manufacturing machinery and automation systems. The versatility of double-acting cylinders allows them to handle a wide range of loads, making them a popular choice for many industrial settings.

Another type is the single-acting cylinder, which operates using hydraulic pressure in one direction only. These cylinders typically return to their original position through a spring or external force. They are often used in applications where the load is lifted, and then the cylinder is allowed to return under gravity, such as in agricultural equipment and lifting devices. Additionally, compact hydraulic cylinders with specialized features, such as those with built-in shock absorbers or cushioned ends, can provide enhanced performance for tasks that involve sudden stops or heavy impacts. Understanding the distinct characteristics of each type helps in choosing the right cylinder for specific needs, ensuring efficiency and reliability in operations.

When working with compact hydraulic cylinders, proper installation and maintenance are crucial to ensure optimal performance and longevity. First, it’s essential to carefully follow the manufacturer’s installation guidelines. Make sure that all connections are secure and that the cylinder is aligned correctly within the system. Misalignment could lead to premature wear or failure. Additionally, consider the environment in which the cylinder operates—factors such as temperature, vibration, and exposure to contaminants can all impact performance. Regularly inspect the installation for any signs of wear or leakage, as early detection can prevent larger issues down the line.

For maintenance, it's advisable to establish a routine schedule for checking hydraulic fluid levels and replacing filters. Keeping the hydraulic fluid clean is vital to prevent damaging contaminants from entering the system. Tips for maintaining compact cylinders include: regularly lubricating moving parts to minimize friction, monitoring operating pressures to ensure they remain within specifications, and checking seals for any signs of deterioration. By implementing these practices, you can extend the service life of your compact hydraulic cylinders and ensure their reliable operation for your applications.

When selecting a compact hydraulic cylinder, one of the most common mistakes is overlooking the importance of application-specific requirements. Many users tend to choose cylinders based solely on dimensions or maximum pressure ratings without fully considering factors such as load weight, operating speed, and required stroke length. According to a report by the International Fluid Power Society, nearly 30% of hydraulic system failures stem from inadequate component selection, emphasizing the need for detailed analysis before making a decision.

Another pitfall is ignoring the operational environment of the hydraulic cylinder. Factors like temperature extremes, exposure to contaminants, and the presence of vibration can severely impact performance and longevity. The Fluid Power Journal notes that environment-related failures can reduce the lifespan of hydraulic components by up to 50%, demonstrating the critical need for suitable materials and protective features. Therefore, it’s crucial to evaluate all operational conditions and select a cylinder that can withstand those challenges effectively. Making these considerations can enhance efficiency and reduce maintenance costs, ensuring optimal functionality for your hydraulic applications.