+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

When it comes to selecting the right backhoe cylinder for your equipment, expert insights and thorough performance data are critical in making an informed decision. Renowned industry specialist, John Smith, an expert in hydraulic systems, emphasizes, "The efficiency and longevity of your backhoe depend significantly on choosing the correct cylinder to match your operational needs." With the increasing demands placed on construction machinery, understanding the specific requirements of backhoe cylinders can lead to improved productivity and reduced costs.

As we delve into the nuances of backhoe cylinders, it becomes essential to consider various factors including size, load capacity, and compatibility with existing machinery. The choice of a backhoe cylinder not only affects the immediate performance of your equipment but also plays a crucial role in the overall functionality and maintenance cost in the long run. This comprehensive guide aims to equip operators and equipment managers with the expert tips and performance data needed to make the best choice from the "2025 Top 10" backhoe cylinders on the market.

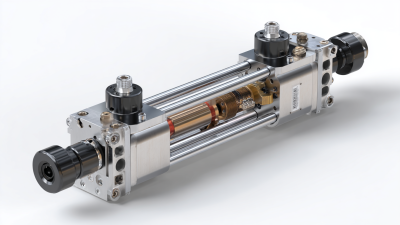

When choosing the right backhoe cylinder, understanding the different types available is crucial. Backhoe cylinders typically come in various designs, including in-line and parallel configurations. The recent advancements in backhoe loader technology, like the introduction of in-line cylinder geometry, have proven to enhance visibility and increase breakout forces significantly. This innovation allows operators to maximize productivity and efficiency on the job site.

Moreover, performance data indicates that modern backhoe cylinders are engineered to handle greater pressures and provide improved lifting capabilities. For example, the integration of advanced hydraulic systems can result in a lift capacity increase of up to 15% compared to older models. This is particularly beneficial in applications requiring substantial power for digging or lifting heavy materials. Understanding these specifications not only aids in selecting the right equipment but also ensures optimal performance and safety during operations.

This chart compares the lifting capacity of different types of backhoe cylinders, including Single Acting, Double Acting, Telescoping, and Rotary cylinders. Understanding their performance can aid in selecting the right one for specific applications.

When selecting backhoe cylinders, several key features should be prioritized to ensure optimal performance and compatibility with your equipment. First and foremost, consider the cylinder's bore size and stroke length, as these dimensions directly influence the lifting capacity and reach of your backhoe. A larger bore allows for greater force, while an appropriate stroke length ensures that the cylinder can achieve the necessary range of motion for effective digging and lifting tasks.

Another crucial factor is the rod material and surface treatment. High-strength steel rods treated with hard chrome plating or other durable coatings can significantly extend the life of the cylinder by resisting wear and corrosion. Additionally, pay attention to the mounting style and configuration to ensure a proper fit with your backhoe arm. Enhanced sealing systems can also improve performance by preventing fluid leaks and contamination, ultimately leading to more reliable operation in demanding environments. By focusing on these key features, you can make an informed decision that enhances your backhoe's efficiency and productivity.

| Feature | Description | Performance Data |

|---|---|---|

| Cylinder Diameter | The width of the cylinder which affects lifting capacity. | 4 - 8 inches |

| Stroke Length | The distance the cylinder can extend. | 24 - 60 inches |

| Material | The material used in the cylinder construction for durability. | High-strength steel |

| Pressure Rating | The maximum pressure the cylinder can withstand. | 2000 - 3000 PSI |

| Mounting Style | Types of mounts that suit various backhoe designs. | Pin-mounted, Clevis-mounted |

| Seal Type | Type of sealing method used to prevent leakage. | Rod seals, Piston seals |

When selecting the right backhoe cylinder, performance metrics are crucial to ensure optimal functionality and efficiency. Key metrics to consider include cylinder pressure ratings, stroke length, and bore size. Understanding these specifications will allow for better compatibility with your equipment's operational requirements and enhance the overall digging performance.

One important tip is to prioritize cylinders with a high-pressure rating, as they generally offer superior lifting capabilities and durability. This ensures that the backhoe can handle tough jobs without risking cylinder failure. Additionally, take into account the stroke length required for the tasks you typically perform; a longer stroke can provide greater reach, while a shorter stroke may be more beneficial for precision tasks.

Another tip is to assess the bore size relative to the load you will be lifting. A bigger bore can provide more force but may come at the expense of speed. Balancing these factors based on your specific operational needs will lead to improved efficiency and prolong the lifespan of the backhoe cylinder. Always refer to the manufacturer's specifications and performance data to make an informed decision.

When selecting backhoe cylinders, avoiding common mistakes can significantly improve performance and lifespan. One prevalent error is failing to consider the compatible specifications of the cylinder with the backhoe model. Each backhoe has unique requirements regarding cylinder size, stroke length, and mounting points. Neglecting these details can lead to improper installation, reduced efficiency, and even equipment failure. Therefore, it's essential to cross-check the manufacturer's guidelines before making any decisions.

Another frequent mistake is overlooking the importance of quality and durability. Many buyers may be tempted to choose less expensive options that compromise material quality or performance. This choice often results in faster wear and potential operational hazards. Investing in high-quality, reliable cylinders might seem costlier upfront but will save money in repairs and downtime in the long run. Always opt for reputable brands and understand the warranty and service options available to ensure that you’re making an informed investment in your equipment's functionality.

Maintaining your backhoe cylinders is crucial for ensuring optimal performance and extending their lifespan. Regular maintenance not only prevents costly repairs but also enhances the efficiency of your machinery. According to industry reports, proper upkeep can increase the lifespan of hydraulic cylinders by up to 40%. Simple practices such as checking for hydraulic fluid leaks, ensuring clean seals, and regularly inspecting for wear can make a significant difference.

One essential tip is to regularly lubricate your backhoe cylinders. Lubrication reduces friction, minimizes wear, and helps maintain hydraulic pressure. Moreover, it’s vital to keep the cylinder rods clean and free from debris to prevent scratches and damage to seals. Another practice is to operate the machinery within its recommended load limits. Overloading can lead to premature wear and failure of hydraulic components.

Additionally, advancements in equipment design, such as new ultra-durable components, are paving the way for improved performance in backhoe systems. As industry innovations increase the power-to-weight ratio and overall efficiency of excavators, the importance of proper cylinder maintenance becomes even more pronounced for operators looking to maximize their investments and maintain high productivity levels.