+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right slewing ring for your project is crucial. According to industry expert John Smith, "The right slewing ring can make or break your project." Slewing rings provide stability and support in heavy machinery and construction equipment. Their selection impacts performance and safety.

When selecting a slewing ring, consider load capacity, size, and material. Weight plays a significant role. A mismatched slewing ring can lead to failures. In various projects, I have witnessed the consequences of selecting an incorrect ring. Issues ranged from mechanical failures to safety hazards.

Analyzing your project's specific demands is essential. Each project presents unique challenges. Thus, the ideal slewing ring must align with those needs. In the fast-paced world of construction, reflecting on these choices can prevent costly mistakes. Selecting a slewing ring should never be taken lightly.

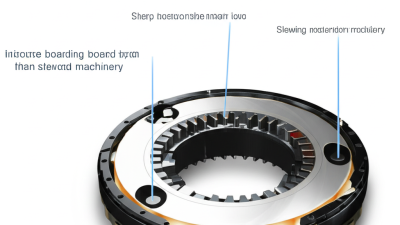

Slewing rings are critical components in many mechanical systems. They enable smooth rotational movement in applications like cranes, wind turbines, and robotics. These rings bear loads from multiple directions, making them essential for stability and strength. Understanding their design and function is crucial for any project.

When selecting a slewing ring, consider the load and rotation requirements. It’s important to analyze the weight distribution and force applied. Not all projects have the same demands. Some might require precision; others may prioritize cost. It can be challenging to find the right balance.

Additionally, the environment plays a role in the choice. Harsh conditions can reduce the lifespan of slewing rings. Exposure to dust, moisture, or extreme temperatures can lead to early failure. Reflecting on these factors will enhance decision-making. It’s essential to assess the risks carefully.

When selecting a slewing ring for your project, key factors play a crucial role. Each application has unique requirements that demand careful consideration. Load capacity is essential. Reports indicate that over 40% of slewing ring failures stem from exceeding load limits. Assess your load conditions meticulously. Consider static and dynamic loads. This understanding helps prevent mechanical failures.

The dimensions and installation space are equally vital. Slewing rings come in various sizes, and fitting one that matches your project’s constraints is crucial. A snug fit can enhance performance. Data reveals that incorrect sizing can increase wear by 25%, compromising lifespan. Don’t overlook environmental factors. Temperature and exposure to contaminants can significantly affect performance.

Materials used in slewing rings should align with the operational environment. Steel and synthetic options differ in strength and resistance to corrosion. Specific industries rely on tailored solutions. For instance, marine applications often demand enhanced rust protection. Feedback shows that overlooking these factors can lead to costly maintenance. Reflect on these considerations during the selection process.

Choosing the right slewing ring involves careful analysis of load capacities and performance requirements. Understanding these factors is crucial for optimizing efficiency.

According to industry reports, slewing rings support various loads, ranging from static to dynamic. The total axial load and radial load play vital roles in selecting the right component.

Load ratings often vary based on mount configuration. A single row design may suffice for lightweight applications. However, applications involving heavier machinery may necessitate a double row or four-point contact configuration.

For instance, slewing rings can handle radial loads up to 100 tons. Still, each application requires specific evaluations to determine optimal load capacity.

Consider environmental conditions as well. Dust and moisture can affect performance. Many slewing rings have modifications for enhanced protection. Neglecting these elements can lead to premature failure.

Companies often overlook the importance of load calculations. Accurate assessments ensure you choose wisely, avoiding costly mistakes down the line.

When selecting a slewing ring, material choice is crucial. Different projects have unique requirements. Understanding environmental implications helps in making informed decisions. For instance, steel slewing rings offer strength and durability, ideal for heavy loads. Reports suggest that about 70% of failures are due to inappropriate material selection.

However, environmental conditions cannot be overlooked. If the slewing ring operates in corrosive environments, stainless steel or coatings may be necessary. Many professionals recommend materials based on specific atmospheres. For example, a study indicates that using non-corrosive materials can extend the lifespan by up to 50%.

One should also consider temperature ranges. Certain materials degrade faster in extreme heat or cold. Project managers often neglect this factor. Failing to assess temperature compatibility can lead to costly replacements. Ultimately, balancing the material's performance against environmental conditions is vital. This balance is not easy to achieve. It's a constant challenge faced in many projects.

| Material | Corrosion Resistance | Load Capacity (kg) | Operating Temperature (°C) | Environmental Suitability |

|---|---|---|---|---|

| Carbon Steel | Moderate | 5000 | -20 to 80 | Indoor Use |

| Stainless Steel | Excellent | 6000 | -50 to 100 | Outdoor and Coastal Areas |

| Aluminum | Good | 3000 | -40 to 70 | Lightweight Applications |

| Bronze | Good | 4500 | -30 to 150 | Marine Applications |

| Polymer | Fair | 2000 | -20 to 60 | Non-Corrosive Environments |

When installing slewing rings, proper alignment is crucial. Misalignment can lead to uneven wear and premature failure. Ensure that the mounting surfaces are clean and flat. Use appropriate tools for tightening the bolts. A torque wrench can help achieve the correct tension. This prevents over-tightening, which might damage the slewing ring.

Regular maintenance is essential for optimal performance. Lubrication should be done at recommended intervals. Use the right type of lubricant. It minimizes friction and extends the life of the slewing ring. Additionally, inspect for signs of wear or damage. Look for noise during operation. Unusual sounds can indicate underlying issues.

Ignoring these practices may lead to costly repairs. Establishing a routine checkup for your slewing rings can save time and resources. It is easy to overlook small signs of wear but addressing them early is important. Choose dedicated personnel to handle maintenance tasks. Their expertise can make a significant difference in performance.