+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

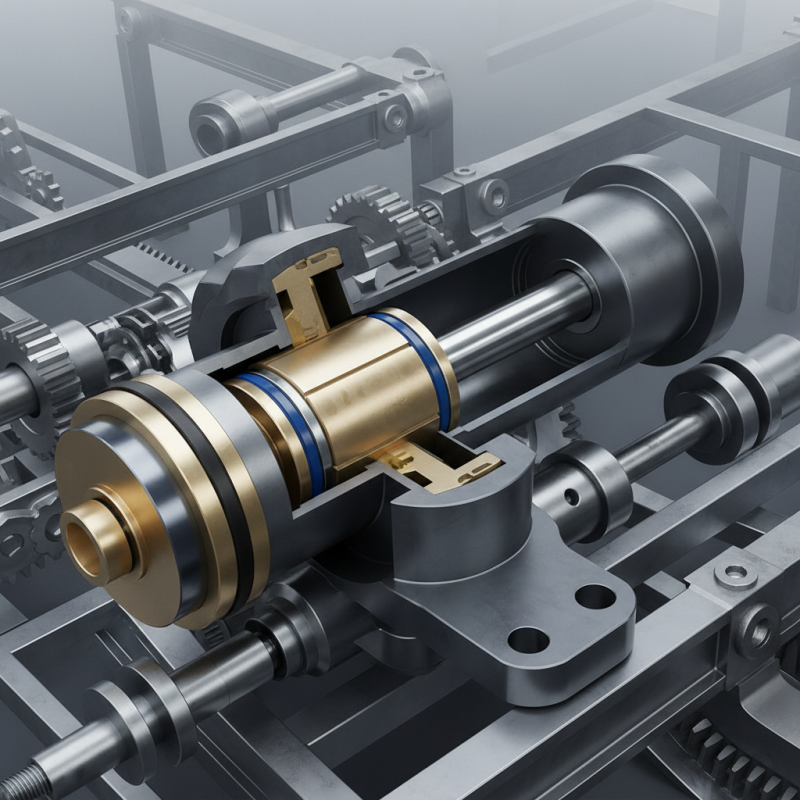

When it comes to industrial machinery, understanding the components that power these systems is essential. Among these components, the Avm Hydraulic Cylinder stands out as a crucial element in various applications, from manufacturing to construction. As businesses increasingly rely on hydraulic systems for efficiency and precision, it becomes imperative for operators and engineers alike to familiarize themselves with the common inquiries surrounding Avm Hydraulic Cylinders. In this exploration, we delve into the top ten questions that often arise about these hydraulic cylinders, shedding light on their functionality, maintenance, and performance.

As we navigate through this guide, we aim to clarify the intricacies of Avm Hydraulic Cylinders, providing valuable insights into their operation and longevity. Whether you are a seasoned professional or a newcomer to the field, understanding these fundamental aspects will not only enhance your knowledge but will also empower you to make informed decisions regarding the use and maintenance of this vital equipment. Join us as we address these common questions and unravel the complexities behind Avm Hydraulic Cylinders, ensuring that you have the essential information you need to succeed in your hydraulic endeavors.

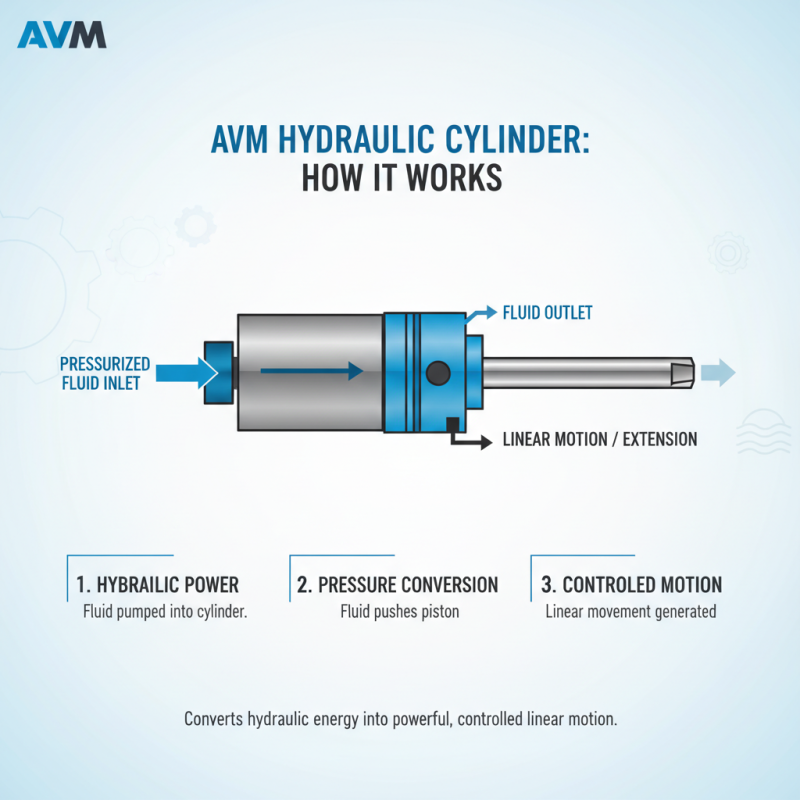

An AVM hydraulic cylinder is a crucial component in many industrial and mechanical applications, designed to convert hydraulic energy into linear motion. This device operates through the principles of hydraulics, utilizing pressurized fluid to create movement. The cylinder consists of a piston inside a cylindrical housing. When hydraulic fluid is pumped into one side of the piston, it creates pressure that forces the piston to move, resulting in a controlled and powerful extension or retraction.

Understanding how an AVM hydraulic cylinder works is essential for ensuring its effective use and maintenance. The system’s efficiency depends heavily on proper fluid levels and the integrity of seals to prevent leaks. Regular checks on these components can significantly reduce the risk of operational failures. It's also important to ensure that the appropriate hydraulic fluid is used, as various applications may require specific types that can withstand different pressures and temperatures.

Tips: Always consult the manufacturer’s guidelines for installation and maintenance to maximize the lifespan of your hydraulic cylinder. Additionally, implementing a routine inspection schedule can help in identifying potential issues before they lead to costly repairs. Monitoring performance indicators like response time and pressure levels can also aid in maintaining optimal operation.

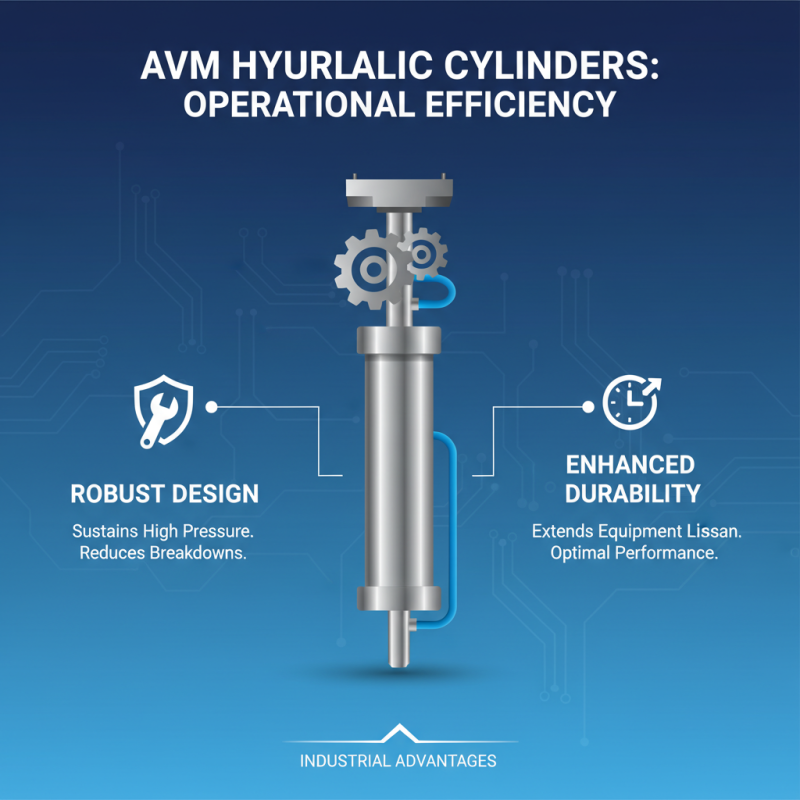

AVM hydraulic cylinders are essential components in various industrial applications, offering a range of significant advantages that enhance operational efficiency. One of the key advantages is their robust design, which enables them to sustain high-pressure environments while maintaining optimal performance. This durability is crucial for industries that rely on heavy machinery, as it reduces the risk of breakdowns and extends the lifespan of the equipment.

Additionally, AVM hydraulic cylinders provide superior flexibility in functionality. They can be tailored to meet the specific needs of different applications, whether in construction, manufacturing, or materials handling. Their ability to operate smoothly and precisely under varying loads allows for greater control over operations, resulting in increased productivity. Furthermore, these cylinders are often designed for easy integration with existing systems, minimizing downtime during upgrades or replacements and ensuring a seamless transition to more advanced hydraulic solutions. This adaptability makes AVM hydraulic cylinders a preferred choice for companies looking to optimize their industrial processes.

Hydraulic cylinders are pivotal components in various industrial applications, and understanding their properties and specifications is essential for optimal performance. The AVM hydraulic cylinder, like many in the sector, is designed to convert hydraulic energy into mechanical energy through controlled fluid pressure. One of the most common specifications is the operating pressure, which typically ranges from 10 to 250 bar in various models. Significant data from industry reports indicate that a remarkable percentage of hydraulic failures stem from exceeding these operational limits, underscoring the necessity of adhering to the manufacturer’s guidelines for pressure ratings.

Another critical aspect of AVM hydraulic cylinders is their construction materials, which directly influence durability and performance. Most cylinders are fabricated from high-strength steel, selected for its tensile strength and fatigue resistance, ensuring longevity and reliability under demanding conditions. Industry analysis reveals that cylinders made from carbon steel can withstand substantial loads and are often treated to improve resistance to corrosion. Additionally, factors like bore diameter and stroke length are tailored based on specific applications, with conventional models offering bore sizes from 32 mm to over 200 mm, thus allowing for flexibility in design and function across various machinery.

Proper maintenance of AVM hydraulic cylinders is essential for ensuring their optimal performance and extending their service life. Regular inspections should be conducted to identify any signs of wear or damage, such as leakage or corrosion, which can significantly impact efficiency. According to industry reports, properly maintained hydraulic cylinders can last up to 50% longer than those that are neglected. This highlights the necessity of establishing a routine checking schedule, where seals, hoses, and connections are assessed for integrity and cleanliness.

Moreover, the lubrication of moving parts is critical. Utilizing the correct type of hydraulic fluid not only helps in reducing friction but also prevents overheating, which can degrade cylinder components over time. A study from the Society of Automotive Engineers (SAE) indicates that approximately 30% of hydraulic failures are directly related to improper fluid maintenance. Therefore, regular fluid checks, changes, and the use of high-quality lubricants tailored for hydraulic systems can prevent premature wear and enhance operational reliability. Implementing these maintenance practices will ultimately lead to improved efficiency and reduced downtime in hydraulic systems, benefiting the overall productivity of operations.

This bar chart illustrates the top 10 common questions regarding AVM Hydraulic Cylinders, showcasing the frequency of inquiries related to maintenance tips, lifespan, and troubleshooting among users. Understanding these common questions can help in maximizing the lifespan of hydraulic cylinders.

When dealing with AVM hydraulic cylinders, understanding typical failures and troubleshooting strategies is crucial for maintaining optimal performance. Common issues include oil leakage, slow operation, and cylinder fatigue. Oil leakage often occurs due to damaged seals or improper installation. Identifying the source of the leak can be achieved through a thorough inspection of the hydraulic connections and seal integrity. If the seals are worn, replacing them promptly can prevent further complications and ensure the cylinder operates efficiently.

Another common failure is slow operation, which can be attributed to low hydraulic fluid levels or contaminated fluid. Regular maintenance checks are essential for monitoring fluid levels and quality, as contaminants can significantly affect performance. If slow movement is noticed, technicians should first check for any obstructions in the hydraulic lines and ensure that the pump is functioning correctly. By addressing these issues proactively, operators can minimize downtime and extend the lifespan of their hydraulic systems. Understanding these troubleshooting techniques aids in rapid identification and resolution, ensuring that hydraulic cylinders operate smoothly under demanding conditions.

| Question | Description | Typical Failures | Troubleshooting Tips |

|---|---|---|---|

| What is a hydraulic cylinder? | A hydraulic cylinder is a mechanical actuator that uses hydraulic energy to produce linear motion. | Leakage, overheating, seal failure | Check the seals and ensure proper fluid levels. |

| What are common causes of hydraulic cylinder failure? | Common causes include contamination, excessive load, and lack of maintenance. | Contamination, wear and tear, improper installation | Regularly change hydraulic fluid and inspect for contamination. |

| How do I maintain my hydraulic cylinder? | Routine inspection and maintenance can prolong the life of hydraulic cylinders. | Insufficient lubrication, corrosion | Maintain proper fluid levels and use appropriate lubricants. |

| What is the role of seals in hydraulic cylinders? | Seals prevent hydraulic fluid from leaking and maintain pressure within the cylinder. | Worn seals, material degradation | Inspect seals regularly and replace if worn or damaged. |

| What should I do if my hydraulic cylinder is leaking? | Identify the source of the leak and take corrective action immediately. | Seal damage, poor connection | Tighten connections and replace damaged seals. |

| How do I know if my hydraulic cylinder is overheating? | Symptoms include excessive noise, reduced performance, and visible heat damage. | Overheating due to excessive load or insufficient cooling | Reduce load and check cooling systems for efficiency. |

| What types of hydraulic cylinders are there? | There are various types including single-acting, double-acting, and telescopic cylinders. | Inappropriate selection for application | Choose the correct type based on load and application requirements. |

| What is the function of a hydraulic accumulator? | A hydraulic accumulator stores energy and provides pressure regulating functions. | Loss of pre-charge, leakage | Check pre-charge levels and inspect for leaks. |

| How can I troubleshoot performance issues? | Identify symptoms like slow operation or erratic movements. | Blockages, low fluid levels | Flush the system and check fluid levels. |