+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right Wheel Lift Cylinder is crucial for enhancing safety and efficiency in transport and logistics. According to industry expert John Smith, "Selecting a quality wheel lift cylinder can significantly reduce operational risks." This insight reflects the importance of making informed decisions.

When assessing options, consider factors like load capacity and material quality. Not all cylinders are created equal, and some may not meet specific requirements. It's vital to evaluate the durability of the cylinder and its compatibility with your equipment.

Additionally, understanding how each Wheel Lift Cylinder operates can prevent common mistakes. A cylinder that works well in one scenario may not be suitable in another. These details matter. Choosing the right product can make or break your daily operations. So, weigh your choices carefully.

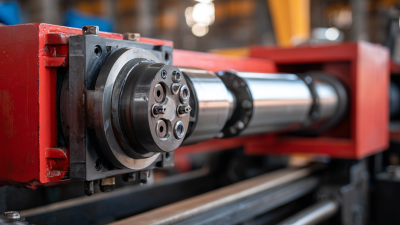

When selecting a wheel lift cylinder, understanding its types and applications is crucial. There are two main types: hydraulic and electric. Hydraulic cylinders rely on fluid pressure to function, making them robust for heavy-duty tasks. Electric cylinders are easier to operate and offer precise control. Both types have unique benefits and applications, but the choice often depends on your specific needs.

Consider the size and weight of the vehicles you typically work with. Larger vehicles require more powerful cylinders. Some may overlook the importance of compatibility with existing equipment. This can lead to costly adjustments later. You'd be surprised how many users neglect weight limits. Always double-check specifications to avoid accidents.

Different applications may need distinct features. A mobile repair shop may prioritize portability, while a fixed location may focus on durability. Some users forget about maintenance, leading to performance issues. Regular checks and servicing can extend the life of your cylinder. It’s essential to reflect on how often your cylinder will be used. Efficiency matters, but safety should always come first.

Choosing the right wheel lift cylinder is crucial. The size and capacity directly impact performance. When selecting a cylinder, consider several key factors.

Weight capacity is paramount. Ensure the cylinder can handle the weight of the vehicles you intend to lift. Assess the maximum weight frequently handled. This helps avoid overloading and potential failures.

Material also plays a significant role. Steel cylinders are strong but may be heavier. Aluminum offers lightweight options, yet might lack durability. Evaluate the balance between strength and weight that fits your needs.

Pay attention to the dimensions. The width and height of the equipment can influence cylinder selection. A poorly sized cylinder can lead to stability issues, affecting safety during operation.

Tip: Always consult manufacturer guidelines. This can help clarify uncertainties. Additionally, regularly inspect your cylinders. Look for signs of wear or damage. This can prevent accidents and costly repairs.

Selecting the perfect wheel lift cylinder requires careful thought. Each choice impacts daily operations. A well-informed decision leads to better efficiency and safety in your work.

| Factor | Description | Recommended Size (inches) | Weight Capacity (lbs) |

|---|---|---|---|

| Cylinder Diameter | The diameter of the cylinder affects the lifting capacity. | 4 | 2,000 |

| Stroke Length | The length of the cylinder's stroke determines how high it can lift. | 12 | 2,500 |

| Material | The material used in the cylinder construction impacts durability. | N/A | N/A |

| Pressure Rating | Maximum operating pressure the cylinder can withstand. | 3,000 PSI | 3,000 |

| Mounting Type | Type of mounting required for installation. | Standard | N/A |

| Temperature Range | The operating temperature range of the cylinder. | -20°F to 180°F | N/A |

| Cylinder Type | Type of cylinder based on application needs (single, double-acting). | Double-Acting | N/A |

| Seal Type | The type of seals used to prevent leaks. | U-Cup | N/A |

| Maintenance Requirements | Frequency and type of maintenance needed for optimal performance. | Quarterly | N/A |

| Cost | Estimated cost of the cylinder including installation. | $500 | N/A |

When selecting a wheel lift cylinder, the materials used in its construction significantly impact performance and longevity. Steel, aluminum, and composite materials are common choices. Each offers unique benefits and drawbacks. For example, steel is known for its strength but can add weight. A 2021 industry report revealed that steel lift cylinders have a lifespan of about 15-20 years with proper care. This lifespan can be reduced with corrosion and neglect, raising questions about maintenance practices.

Aluminum, on the other hand, is lighter and resistant to rust. However, it might not withstand heavy loads as well as steel. In practice, aluminum cylinders can last around 10-15 years. This discrepancy highlights the importance of matching material choice to usage scenarios. According to a recent study, nearly 30% of users reported premature failure due to improper selection of materials based on their typical lifting tasks.

Composite materials have entered the market, offering a balance between weight and strength. They can withstand harsh environments but are often more expensive. Many users are uncertain about their long-term performance. Some reports suggest that composites may exceed the lifespan of steel, but more data is needed for definitive conclusions. Examining these materials reveals the complexity of choosing the right wheel lift cylinder, emphasizing that users must carefully assess their needs and make informed decisions.

Maintaining wheel lift cylinders can greatly extend their lifespan. Regularly checking hydraulic fluid levels is crucial. Low fluid can lead to poor performance. In addition, inspect all seals for wear. A worn seal may cause leaks, impacting efficiency.

Using the right cleaning methods is essential. Avoid harsh chemicals that could damage components. Instead, use mild soap and water for routine cleaning. Pay special attention to any dirt or grime that accumulates. These can lead to corrosion over time.

Lastly, it’s vital to consider the environment in which your wheel lift operates. Exposing it to extreme weather can accelerate wear. Try to keep the equipment in a controlled space. Reflect on your maintenance routine periodically. Adjust it if you notice any issues or changes. This proactive approach ensures durability and reliability.

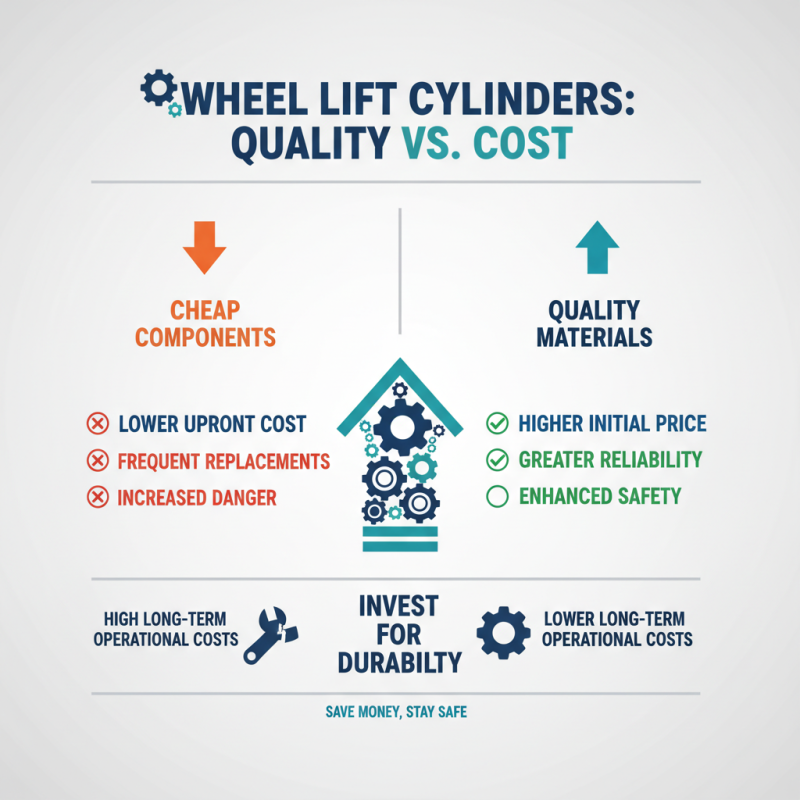

When budgeting for wheel lift cylinders, understanding quality versus cost is crucial. Cheap components can lead to frequent replacements and potentially dangerous situations. Investing in quality materials often pays off in the long run. Think about long-term operational costs rather than just upfront expenses. Sometimes, a slightly higher price means greater reliability.

Examine specifications carefully. A cylinder might seem affordable but lacks durability. Check materials and design. Ask for detailed quotes to clarify costs. Hidden fees can inflate your budget. It’s essential to balance functionality with price.

Consider maintenance costs as well. Low-quality cylinders may involve more repairs over time. This can add up considerably. Contemplating a cylinder’s lifecycle helps you make informed choices. You might save money initially but could face significant expenses later. Proper planning is key to ensuring quality without overspending.