+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

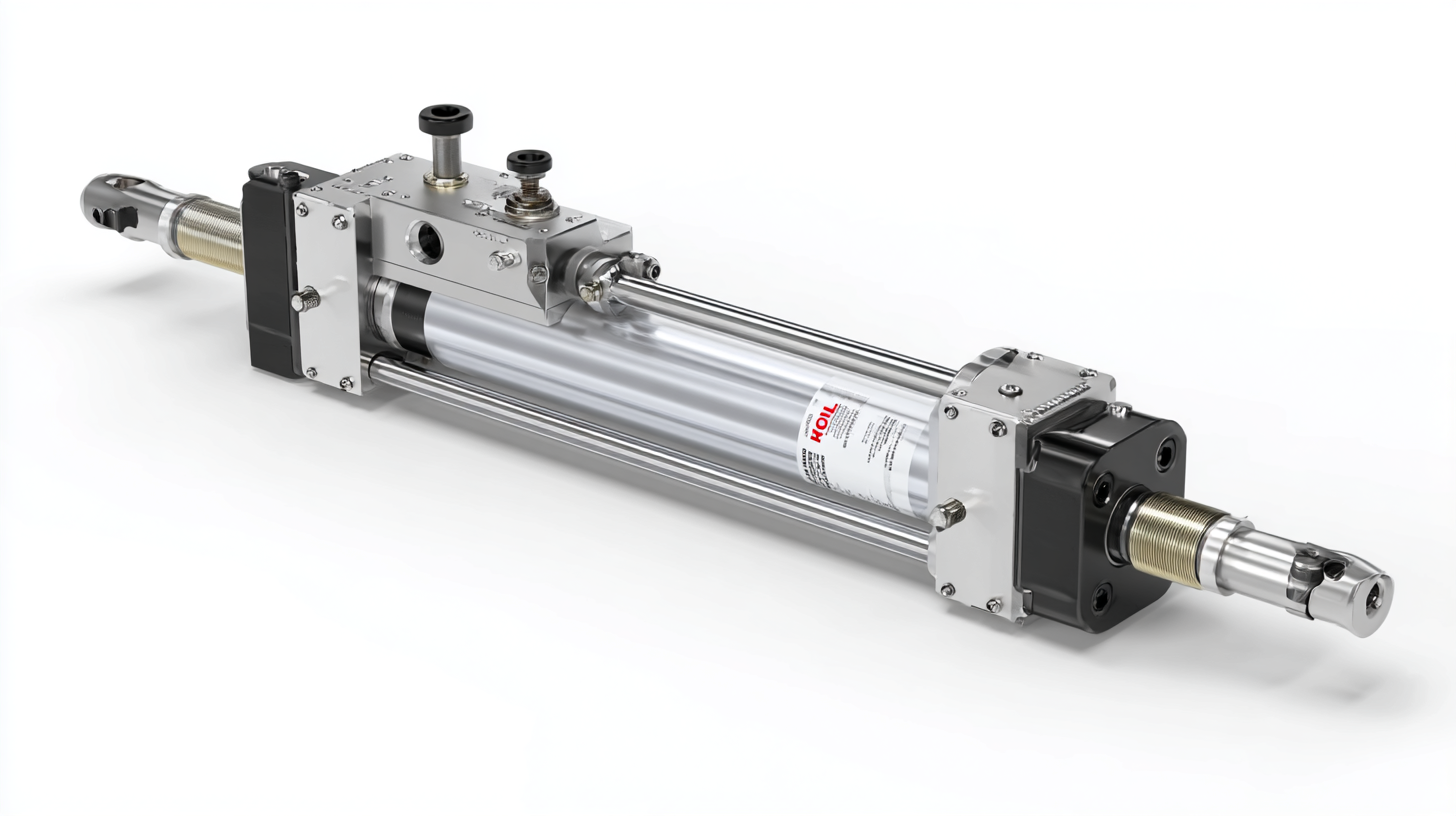

In today's fast-paced industrial landscape, the quest for enhanced efficiency and productivity drives innovation across various sectors. One crucial component that has emerged as a linchpin in achieving these goals is the Hol Mac Hydraulic Cylinders. Renowned for their durability and performance, these cylinders are increasingly becoming the preferred choice for a multitude of industrial applications—from manufacturing to construction. As businesses strive to streamline operations and reduce downtime, the demand for Hol Mac Hydraulic Cylinders continues to grow, underscoring their significance in modern machinery. This article delves into the reasons behind this escalating demand, exploring how these hydraulic cylinders not only improve operational efficiency but also contribute to overall cost-effectiveness, making them an indispensable asset in the industrial toolkit.

Hydraulic cylinders play a crucial role in modern industrial applications, serving as the backbone for various machinery and processes. According to a report by Allied Market Research, the global hydraulic cylinder market is projected to reach $24.5 billion by 2026, growing at a CAGR of 5.4% from 2019. This growth can be attributed to the increasing demand for automated solutions in industries such as construction, manufacturing, and agriculture, where hydraulic systems enhance performance and efficiency.

The versatility of hydraulic cylinders allows them to handle heavy loads with precision, making them essential in powering equipment like cranes, excavators, and forklifts. A study from Research and Markets highlights that the construction sector is the largest consumer, accounting for approximately 38% of the hydraulic cylinder market share in 2021. As industries continue to evolve, the need for reliable and efficient hydraulic solutions becomes increasingly important to maintain competitive advantage and optimize operational output. The ongoing innovations in hydraulic technology, such as the development of smart cylinders, further emphasize the vital importance of these components in ensuring operational success.

Hydraulic cylinders play a pivotal role in industrial applications, and the demand for Hol Mac hydraulic cylinders is climbing rapidly due to their key features that enhance performance. Notably, these cylinders are designed for exceptional durability and efficiency, making them a preferred choice in sectors such as agriculture, construction, and manufacturing. According to recent industry reports, the global hydraulic cylinder market is projected to reach approximately $24 billion by 2027, driven by the increasing need for automation and robust machinery.

One of the standout features of Hol Mac hydraulic cylinders is their advanced sealing technology, which significantly reduces leakage and increases operational lifespan. This translates to lower maintenance costs and enhanced machine reliability. Additionally, the cylinders are scalable, allowing for a wide range of applications across different industrial sectors. As industries focus on boosting productivity and reducing downtime, choosing cylinders that meet these criteria is essential.

One of the standout features of Hol Mac hydraulic cylinders is their advanced sealing technology, which significantly reduces leakage and increases operational lifespan. This translates to lower maintenance costs and enhanced machine reliability. Additionally, the cylinders are scalable, allowing for a wide range of applications across different industrial sectors. As industries focus on boosting productivity and reducing downtime, choosing cylinders that meet these criteria is essential.

Here are some tips to consider when selecting hydraulic cylinders:

The demand for hydraulic cylinders is on the rise across various industrial sectors, indicating a significant shift in operational efficiencies. Industries such as construction, agriculture, and manufacturing are increasingly leveraging hydraulic systems to improve productivity and reduce operational costs. According to a recent report by Markets and Markets, the global hydraulic cylinder market is projected to grow from USD 12.5 billion in 2021 to USD 16.9 billion by 2026, with a compound annual growth rate (CAGR) of 6.5%. This growth is largely driven by the expansion of infrastructures and the need for advanced machinery that is reliant on hydraulic technology.

One company responding to this burgeoning demand is Hol-Mac Corporation, which has recently announced an expansion in Bay Springs, resulting in the creation of 31 new jobs. This development not only highlights the company's commitment to meeting the increasing market need but also reflects broader trends in the industry where manufacturers are focusing on enhancing their production capabilities. As industries continue to adopt innovative hydraulic solutions, the significance of reliable hydraulic cylinders will become paramount in ensuring operational efficiency and maximizing productivity across various applications.

In recent years, the demand for hydraulic cylinders has surged, particularly in industrial applications where efficiency and reliability are paramount. A comparative analysis of Hol Mac hydraulic cylinders versus other leading brands reveals key advantages that can influence procurement decisions. According to a recent industry report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach $18.8 billion by 2025, driven by increasing automation and infrastructure development. This growing market highlights the need for manufacturers to consider performance metrics seriously when selecting hydraulic cylinders.

Hol Mac hydraulic cylinders stand out for their innovative design and performance capabilities. Unlike many competitors, Hol Mac's products leverage advanced materials that increase durability while reducing maintenance costs. For instance, a study from the National Fluid Power Association (NFPA) indicates that hydraulic systems utilizing high-efficiency cylinders can save up to 15% in operational energy compared to standard hydraulic solutions. Additionally, the flexibility in customization offered by Hol Mac allows for tailored solutions, addressing specific industry challenges more effectively than generic options from other brands. This adaptability ensures that businesses can enhance productivity while minimizing downtime, underscoring the growing preference for Hol Mac in the competitive hydraulic cylinder landscape.

| Feature | Hol Mac | Brand A | Brand B | Brand C |

|---|---|---|---|---|

| Load Capacity (tons) | 20 | 18 | 22 | 19 |

| Operating Pressure (bar) | 250 | 240 | 260 | 230 |

| Stroke Length (mm) | 500 | 480 | 520 | 490 |

| Weight (kg) | 150 | 145 | 160 | 155 |

| Warranty (years) | 3 | 2 | 3 | 2 |

The landscape of hydraulic cylinder technology is rapidly evolving, driven by the increasing demand for efficiency and performance in industrial applications. As manufacturers seek to optimize operations, the focus has shifted towards advanced hydraulic systems that offer longer service life, reduced energy consumption, and enhanced reliability. Emerging trends include the integration of smart technology, allowing for real-time monitoring and adjustments, which significantly improves system efficiency.

Tips for improving hydraulic cylinder efficiency include regular maintenance checks to identify wear and tear early, as well as verifying that all seals and connections are airtight to prevent leaks. Additionally, considering the use of lightweight materials can enhance responsiveness and reduce overall system load, leading to more efficient operations.

Another notable trend is the advancement in materials and design, with innovations such as hybrid cylinders that combine traditional hydraulics with electric drives. This not only boosts performance but also reduces carbon footprints in line with growing environmental standards. Adapting to these latest technologies can provide companies with competitive advantages while supporting sustainability initiatives.