+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

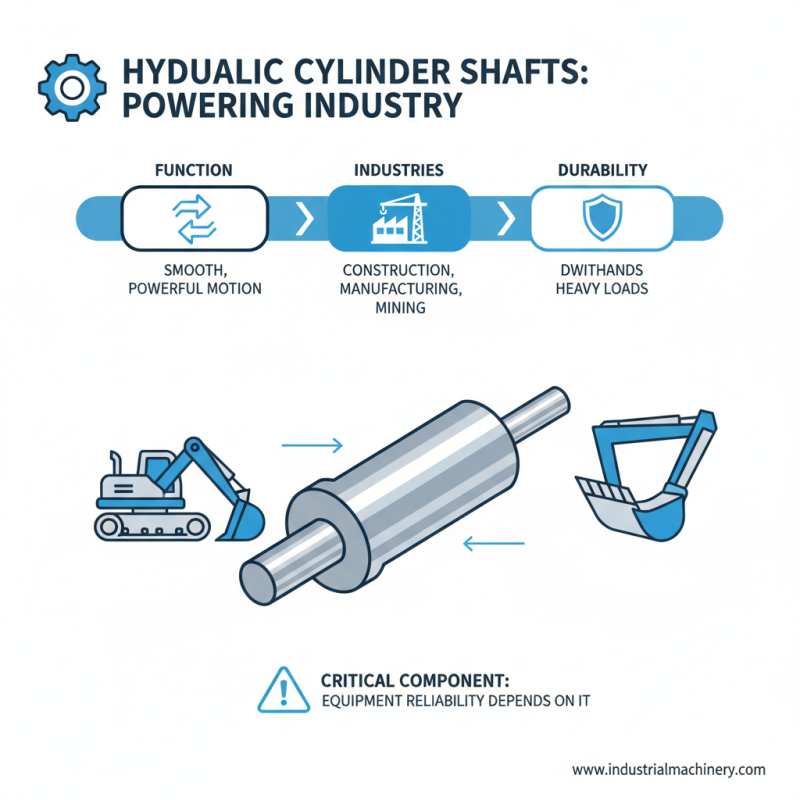

In the world of industrial machinery, the hydraulic cylinder shaft plays a crucial role. Expert Henry Clayton, a leading engineer in hydraulic systems, emphasizes, “The hydraulic cylinder shaft is where the power meets precision.” This component is essential for converting hydraulic energy into mechanical motion.

Hydraulic cylinder shafts are often used in various applications, such as construction and manufacturing. They are designed to withstand high pressure and heavy loads. However, the design isn't always perfect. Issues like wear or misalignment can occur, impacting performance.

Understanding how a hydraulic cylinder shaft functions is vital. These components use hydraulic fluid to create pressure, moving the shaft within the cylinder. When problems arise, facilities must analyze potential failures. Attention to detail in maintenance can prevent costly downtimes. The hydraulic cylinder shaft's reliability is indispensable for efficient operations.

A hydraulic cylinder shaft is a crucial component in hydraulic systems. It converts fluid power into mechanical energy. This shaft can be cylindrical, allowing it to move smoothly within the cylinder. Its primary purpose is to transmit forces and motion. It plays a key role in heavy machinery and various applications, from construction to manufacturing.

The hydraulic cylinder shaft's efficiency can significantly impact system performance. Research indicates that proper maintenance can improve lifespan by 30%. However, wear and tear are inevitable. Friction and contamination can lead to damage. Regular inspection is essential. Some operators may overlook this, resulting in costly failures.

In many cases, operators fail to recognize the importance of the shaft’s alignment. Misalignment can reduce efficiency and increase wear. Industry reports suggest that misaligned shafts can cause a 10% decrease in performance. Understanding these factors is crucial. Poor maintenance or neglect may lead to unanticipated downtime or operational issues. It's beneficial to invest in training and best practices.

Hydraulic cylinder shafts play a crucial role in fluid power systems. They are the key components that transfer force generated by hydraulic pressure into mechanical motion. These shafts are typically made from strong materials to withstand high pressure and stress. In many applications, they convert the linear motion of hydraulic fluid into movement, driving machinery or vehicles.

In a hydraulic system, the efficiency of the cylinder shaft is vital. A well-designed shaft reduces friction and enhances smooth operation. However, some shafts may become misaligned or wear out over time. Such issues can lead to inefficient performance, increased energy consumption, and potential failures. Regular maintenance is necessary to ensure optimal functioning. Neglecting these details could result in costly repairs or downtime.

Different applications demand various designs and sizes of hydraulic shafts. For instance, construction equipment often requires larger, more robust shafts. In contrast, smaller machines may utilize lightweight versions. Understanding the specific requirements of a system is essential. Engineers must reflect on the unique challenges each application presents to optimize performance.

| Dimension | Value | Description |

|---|---|---|

| Diameter | 25 mm | The outer diameter of the hydraulic shaft. |

| Length | 500 mm | The total length of the hydraulic shaft. |

| Material | Steel | Commonly used material for its strength and durability. |

| Operating Pressure | 200 bar | Maximum pressure at which the hydraulic system operates. |

| Stroke Length | 300 mm | The distance the piston travels within the cylinder. |

A hydraulic cylinder shaft is crucial in various machinery. Its main purpose is to convert hydraulic energy into mechanical motion. This transformation relies heavily on the components used in the shaft's construction. Materials play a significant role in ensuring strength and durability while also considering weight.

Typically, hydraulic cylinder shafts are made from high-strength steel or aluminum alloys. These materials resist deformation and wear under high pressure. Steel provides excellent tensile strength, while aluminum is lighter and easier to work with. However, reliance on these materials can have drawbacks. For instance, steel is heavier, which can affect the overall efficiency of some machines. Aluminum, though lighter, may not always withstand extreme conditions.

The design of the shaft must accommodate various factors. Tolerances and surface finishes are significant. A well-crafted shaft reduces friction and enhances efficiency. It is essential to balance performance with cost-effectiveness. Financial constraints can lead to compromises in material quality and design precision. This decision-making process often requires reflection on long-term impacts versus short-term savings.

Hydraulic cylinder shafts are vital components in various machines. They convert hydraulic energy into mechanical force. The design allows fluid pressure to move the shaft in a controlled manner. This action provides linear motion, essential in many applications, from construction to manufacturing.

The mechanics of hydraulic cylinder shafts involve precise fluid dynamics. When fluid is directed into the cylinder, it pushes against the shaft. The pressure generates motion, which can lift or move heavy loads. This process relies on a balance between pressure and load. If the fluid pressure exceeds the load, the operation runs smoothly. Otherwise, it may stall or cause damage.

Tips: Regular maintenance is crucial. Inspect seals and connections frequently. Check for leaks, as any loss can reduce efficiency. Ensure that the hydraulic fluid remains clean. Contaminated fluid can lead to wear and tear. Always use protective measures during operation. This not only ensures safety but also prolongs the lifespan of the equipment.

Hydraulic cylinder shafts are integral to various industries. They provide smooth, powerful motion for machinery. In construction, these shafts drive excavators and bulldozers. They endure heavy loads and demanding conditions daily. Each part must be durable; otherwise, the equipment may fail.

In the automotive sector, hydraulic cylinder shafts are crucial. They are used in lifts and presses. These applications require precision and reliability. When a shaft bends or wears out, it can halt production. Maintenance is essential, yet some companies overlook this aspect. This can lead to unexpected downtime.

Aerospace also relies on hydraulic cylinder shafts. They assist in controlling flight systems and landing gear. Any malfunction can be catastrophic. Thus, rigorous testing is vital in this field. However, not all manufacturers prioritize quality checks, leading to major issues. This inconsistency highlights the need for improved standards.