+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Maintaining your Dump Bed Cylinder is crucial for efficiency and safety. According to industry expert John Smith, “A well-maintained cylinder is the backbone of a reliable dump system.” Neglect can lead to costly downtime and repairs.

Regular inspections and maintenance checks are essential. Look for leaks and corrosion regularly. These issues can impair performance significantly, leading to failures during operation. Issues often arise when owners underestimate the importance of routine care. The right attention can prevent many common problems.

Every user should consider their specific usage patterns. Factors like load weight and frequency of use play a significant role. Reflecting on your maintenance habits can reveal areas for improvement. Are you diligent about timely inspections? Your Dump Bed Cylinder deserves attention, just like any critical equipment.

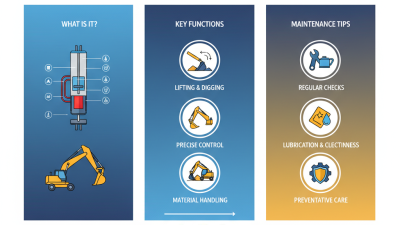

Regular maintenance for dump bed cylinders is essential for ensuring optimal performance. These hydraulic systems can face wear and damage over time due to heavy loads and exposure to the elements. If not properly maintained, they could fail when you need them most. Regular inspections help to identify any leaks or signs of wear. Simple checks can save you from costly repairs later.

Hydraulic fluid levels should be checked frequently. Low fluid can lead to inefficient operation. Ensure that seals and fittings are secure. Any signs of corrosion or damage may require immediate attention. Neglecting these small details might lead to bigger problems down the road. Additionally, cleaning the cylinder and surrounding areas removes dirt and debris. A clean environment promotes better performance.

Routine maintenance may feel repetitive, but it's crucial. Missing a step could result in diminished efficiency. Take note of any performance changes. A sudden decrease might indicate a problem. Keeping a log of maintenance tasks can also be helpful. It might not guarantee perfection, but it fosters a proactive approach. Spend time understanding how your system operates. This knowledge will aid in better maintenance.

| Maintenance Task | Frequency | Key Benefits |

|---|---|---|

| Inspect for Leaks | Monthly | Prevents fluid loss and maintains hydraulic efficiency |

| Clean Cylinder and Components | Every 3 months | Reduces wear and protects against corrosion |

| Check Hydraulic Fluid Levels | Monthly | Ensures proper operation and avoids component damage |

| Inspect Seals and O-rings | Every 6 months | Maintains seal integrity and prevents leaks |

| Lubricate Moving Parts | Every 2 months | Reduces friction and prolongs the life of components |

| Test Load Capacity | Annually | Ensures the system operates safely under load |

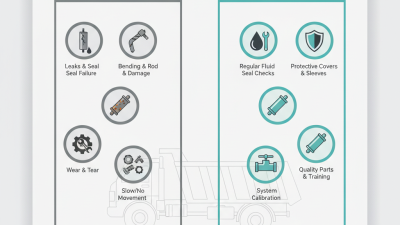

Hydraulic cylinders are essential for dump bed functionality. Over time, they can show signs of wear and tear. Recognizing these signs early can prevent bigger issues. Look out for leaks around the seals. If you notice fluid pooling beneath your cylinder, it's a clear warning sign. A small leak can quickly worsen, disrupting operation.

Another common issue is unusual noises. If your hydraulic cylinder starts to make grinding or hissing sounds, it could indicate internal damage. Pay attention to erratic movements as well. A cylinder should extend and retract smoothly. If it hesitates or jolts, it might be time for inspection.

Inspect the cylinder for scratches or dents. Any visible damage can lead to further complications. The rod should be clean and free of rust. Dirt and debris can cause seals to wear out faster. Don’t ignore these details; maintenance is critical. Regular checks on these signs can help prolong the cylinder's life.

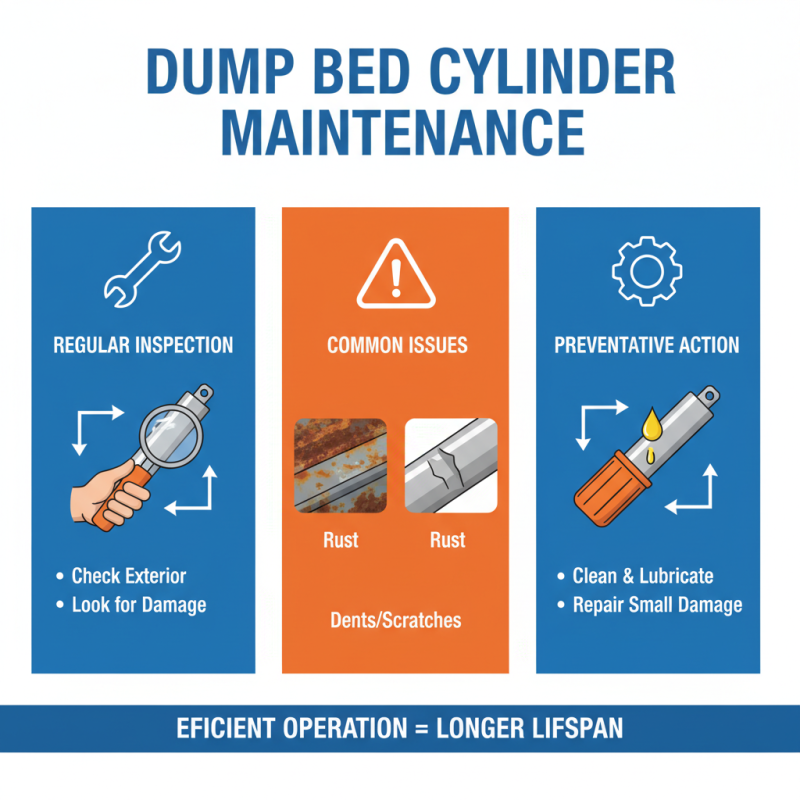

Maintaining a dump bed cylinder is crucial for efficient operation. Regular inspection is the key. Begin by checking the cylinder's exterior. Look for signs of rust or dents. A small scratch might seem harmless. However, it can lead to bigger issues later.

Next, inspect the seals. These components prevent hydraulic fluid leaks. If you notice any damage on the seals, replace them immediately. A worn seal can cause poor performance. Pay attention to any fluid pooling under the cylinder. This indicates a potential problem.

Finally, examine the hydraulic connections. Secure any loose fittings. Tighten them carefully to avoid stripping the threads. A small oversight here could result in major leaks. Always review your work once finished. It's easy to miss something. Taking the time to ensure everything is in good condition can save you from future headaches.

To maintain your dump bed cylinder effectively, proper lubrication is key. Start by choosing the right lubricant. Different cylinders may require specific types of oils. Check the manufacturer's recommendations if available. Regular application of grease or oil can prevent corrosion and excessive wear.

Consider the environment in which the cylinder operates. Dust and debris can hinder performance. Cleaning the cylinder is essential before applying lubricant. Wipe off any grime. Inspect seals and fittings for damage. A damaged seal can lead to leaks, compromising performance.

Implement a routine lubrication schedule. Don’t wait for the cylinder to show signs of wear. This proactive approach saves time and money. If you notice any irregularities, such as unexpected noises, it might be a sign of inadequate lubrication. Regular checks increase longevity, but remember that over-lubricating can also pose risks. Balance is crucial for optimal performance.

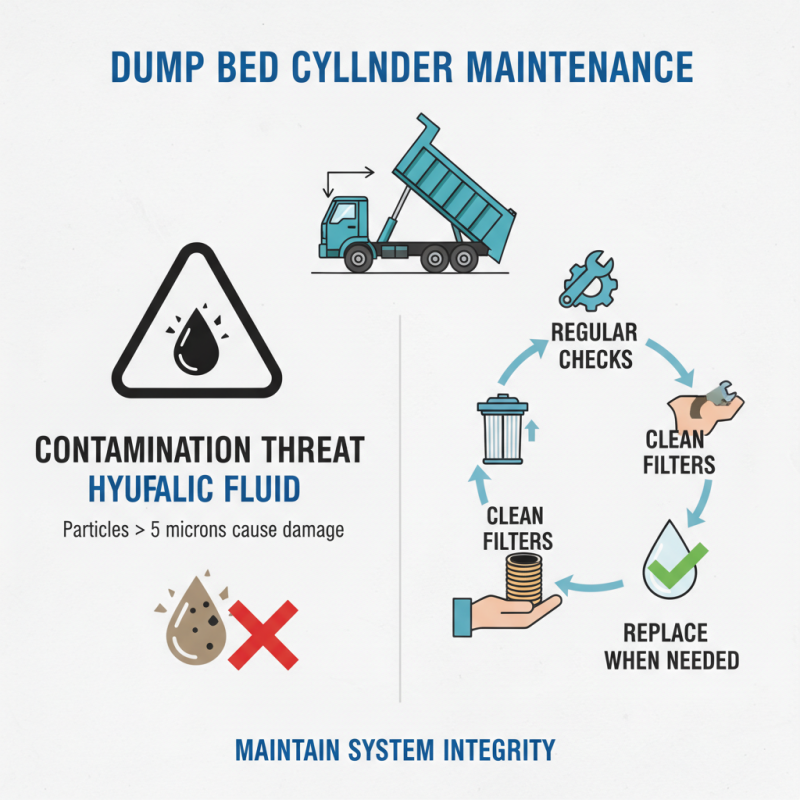

Keeping your dump bed cylinder in peak condition requires vigilance. One of the biggest threats is hydraulic fluid contamination. According to industry reports, particles as small as 5 microns can cause substantial damage. This emphasizes the need for clean hydraulic environments. Regularly check filters to ensure they are functioning effectively. Replace them when necessary to maintain system integrity.

Leaks are another common issue. They can lead to wasted resources and unsafe conditions. A study indicated that nearly 15% of hydraulic systems experience leaks. Inspect hoses and connections frequently. Look for signs of wear or cracks that could allow fluid to escape. Tightening fittings can sometimes solve minor leaks, but a thorough evaluation is essential.

Training your team on these best practices is critical. Without proper knowledge, even the best systems can falter. Implement preventive measures like regular maintenance schedules. Data shows that proactive maintenance can extend the life of hydraulic systems by up to 30%. This results in cost savings and improved performance. It's a proactive approach that pays off in the long run.