+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In the ever-evolving world of construction and heavy machinery, the features, benefits, and applications of the Outrigger Cylinder play a pivotal role in enhancing operational efficiency and safety. Renowned industry expert, Dr. John Smith, a leading engineer in hydraulic systems, emphasizes, "The design and functionality of Outrigger Cylinders are crucial for stabilizing equipment and ensuring optimal performance under varying loads." This insight underscores the importance of understanding the key attributes that make these cylinders indispensable in various applications.

Outrigger Cylinders not only contribute to the stability of cranes and other lifting equipment but also significantly influence their performance and safety. By extending horizontally, these cylinders create a sturdy foundation that allows heavy machinery to operate efficiently, particularly in uneven terrains. This article will delve into the essential features of Outrigger Cylinders, illustrating how their design and technological advancements lead to improved functionality across multiple sectors, from construction to entertainment.

As we explore the myriad benefits and applications of Outrigger Cylinders, it becomes evident that these components are not merely functional elements, but rather, vital instruments that enhance the safety and effectiveness of heavy lifting operations. Understanding the intricacies of Outrigger Cylinders is essential for operators and engineers alike, as it directly impacts project outcomes and overall machinery performance.

Outrigger cylinders are essential components in various applications, particularly in

construction and heavy machinery sectors. One of the key

characteristics of these cylinders is their ability to provide stability

and support. Outrigger cylinders extend outward from the base of equipment like cranes and

excavators, creating a wider footprint that enhances balance during operation. This feature

is crucial, especially when dealing with heavy loads or performing tasks

on uneven surfaces.

Another notable characteristic is the hydraulic mechanism employed in outrigger cylinders,

which allows for smooth and precise extension and retraction. This hydraulic system enables

operators to quickly adjust the positioning of the equipment, ensuring maximum efficiency and

safety on the job site. The robust construction of outrigger cylinders also means they are

designed to withstand harsh environments, providing longevity and reliability in

demanding conditions.

Tips: When choosing outrigger cylinders for your applications, consider factors such as

load capacity, extension height, and

environmental resistance. Regular maintenance is also vital;

check for leaks and wear to ensure

optimal performance. Proper usage and care will significantly extend the lifespan and efficiency

of these critical components in your machinery.

Outrigger cylinders are essential components in various industries, especially in construction and heavy machinery, offering a range of significant benefits. One of the primary advantages of using outrigger cylinders is their ability to enhance stability in machinery during operation. By extending the base of equipment, outriggers provide critical support, minimizing the risk of tipping over and ensuring safer lifting operations. This stability is particularly vital in projects that involve heavy loads and uneven terrain, where traditional lifting methods may pose greater risks.

In addition to improved safety, outrigger cylinders can boost operational efficiency. By facilitating quicker setup times, they allow equipment to be positioned optimally without extensive ground preparation. This efficiency not only saves time but also reduces labor costs, as fewer personnel are required to stabilize machinery. Furthermore, the adaptability of outrigger cylinders enables them to be used in various applications, ranging from cranes and aerial lifts to mobile scaffolding systems, making them a versatile choice for diverse tasks in construction and beyond.

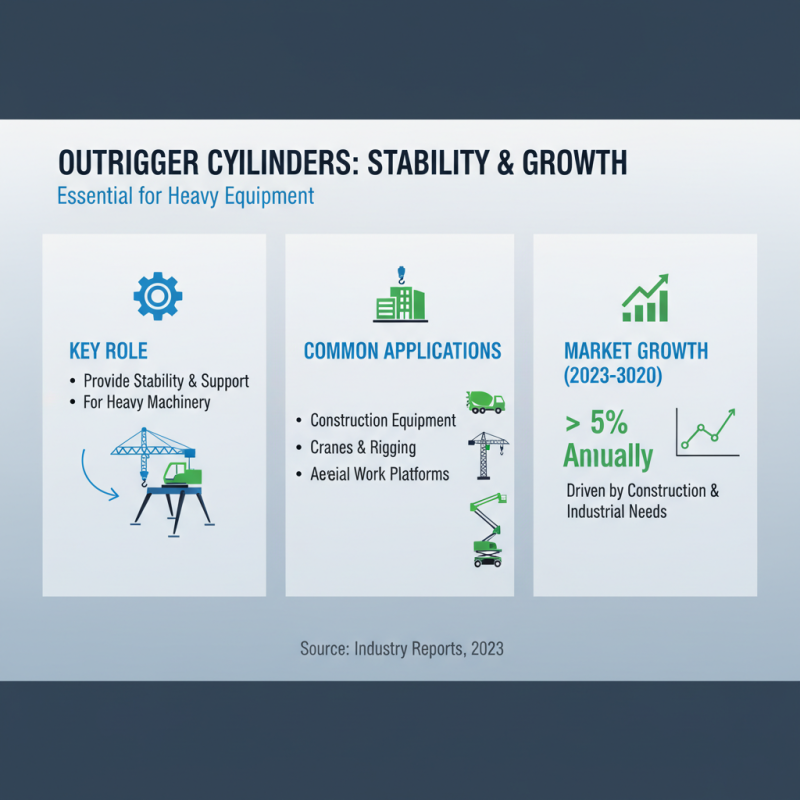

Outrigger cylinders play a crucial role in various industries, providing stability and support for heavy equipment and machinery. Common applications of these cylinders are found in construction, cranes, and aerial work platforms. According to industry reports, demand for outrigger cylinders is projected to grow by over 5% annually through 2030, driven by the increasing need for reliable lifting and stabilizing solutions in construction and industrial settings.

In the construction sector, outrigger cylinders enhance the safety and efficiency of lifting operations. They are often used in mobile cranes, ensuring that the equipment remains stable during operation. A recent study highlighted that nearly 60% of construction accidents involve improper equipment stabilization, which can be significantly mitigated by implementing well-designed outrigger systems. Their hydraulic mechanisms provide precise control over the stability, making them essential for high-rise construction and maintenance work.

Tips: When selecting outrigger cylinders, consider factors such as load capacity, extension reach, and hydraulic efficiency to ensure optimal performance for your specific application. Regular maintenance of these cylinders is also critical to avoid unexpected downtime and ensure safe operation.

In addition to construction, outrigger cylinders are widely utilized in the automotive industry, particularly in vehicle recovery and towing operations. They assist in stabilizing vehicles during the recovery process, reducing the risk of accidents. With the automotive sector rapidly evolving, incorporating advanced hydraulic technologies in outrigger systems is becoming increasingly important to meet demanding operational requirements and enhance safety standards.

Proper maintenance of outrigger cylinders is essential to ensure their optimal performance and longevity. One key aspect of maintenance is regular inspection for leaks or signs of wear. Operators should routinely check the hydraulic fluid levels and lines to prevent any unexpected failures during operation. Keeping the hydraulic fluid clean and at the appropriate levels helps maintain the efficiency of the cylinders, which is critical for stabilizing equipment on uneven terrain.

Another important maintenance tip involves lubricating moving parts to enhance performance. This includes greasing the pivot points and ensuring that seals are intact to protect against contaminants. Additionally, it's advisable to store the equipment in a dry and shaded area when not in use to prevent corrosion and other environmental damages. Establishing a regular maintenance schedule can significantly extend the lifecycle of outrigger cylinders, ensuring that they function reliably when needed. By following these simple yet effective maintenance practices, operators can maximize the effectiveness of their equipment, improving safety and operational efficiency.

In the realm of heavy machinery and construction, the choice between outrigger cylinders and traditional cylinders can significantly impact operational efficiency and stability. Outrigger cylinders are designed to provide superior support and enhance the safety of machinery during operations. Unlike traditional cylinders, which often offer limited lateral support, outrigger cylinders extend horizontally, distributing the load more evenly. This feature is particularly beneficial in uneven terrains or when dealing with heavy loads, reducing the risk of tipping and enhancing overall stability.

According to a recent industry report by the International Heavy Equipment Association, machines equipped with outrigger cylinders showcase up to a 30% increase in stability compared to those using traditional cylinder systems. This is critical in environments where precision and safety are paramount, such as in construction or crane operations. Additionally, the enhanced hydraulic mechanisms in outrigger cylinders allow for quicker retraction and extension, leading to increased productivity on job sites.

Tips: When selecting cylinders for your machinery, consider the specific demands of your work environment. Utilizing outrigger cylinders can greatly improve safety and operational efficiency, particularly in challenging conditions. Always consult with engineering professionals to assess the best cylinder type suited for your particular applications, and invest in regular maintenance to ensure peak performance.