+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

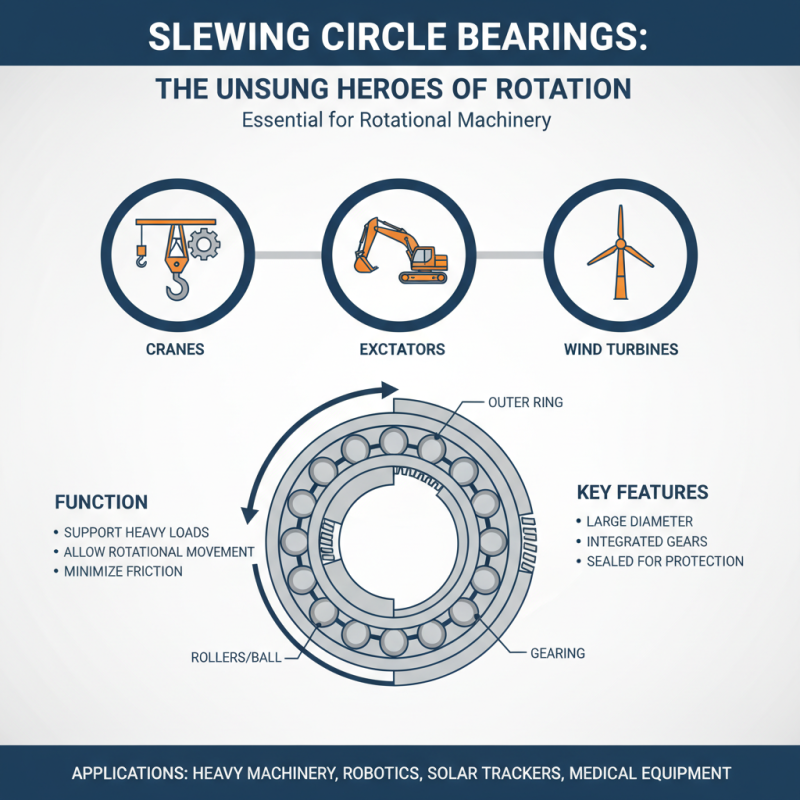

A Slewing Circle Bearing is a crucial component in many heavy machinery applications. It allows rotation and movement with high precision and load capacity. This bearing is often seen in cranes, excavators, and wind turbines. Understanding its function is vital for engineers and operators alike.

At its core, a Slewing Circle Bearing consists of an inner and outer ring, a cage, and rolling elements. These components work together to enable smooth rotation. Some may overlook the importance of maintaining this bearing. Neglect can lead to breakdowns and costly repairs. Regular inspections can prevent these issues.

Moreover, the design varies significantly based on its application. Heavy-duty versions for cranes face different stresses than those used in smaller applications. Recognizing this diversity is essential. The complexity of its operation invites deeper reflection on engineering design and maintenance strategies. Each aspect of its function impacts overall machinery performance.

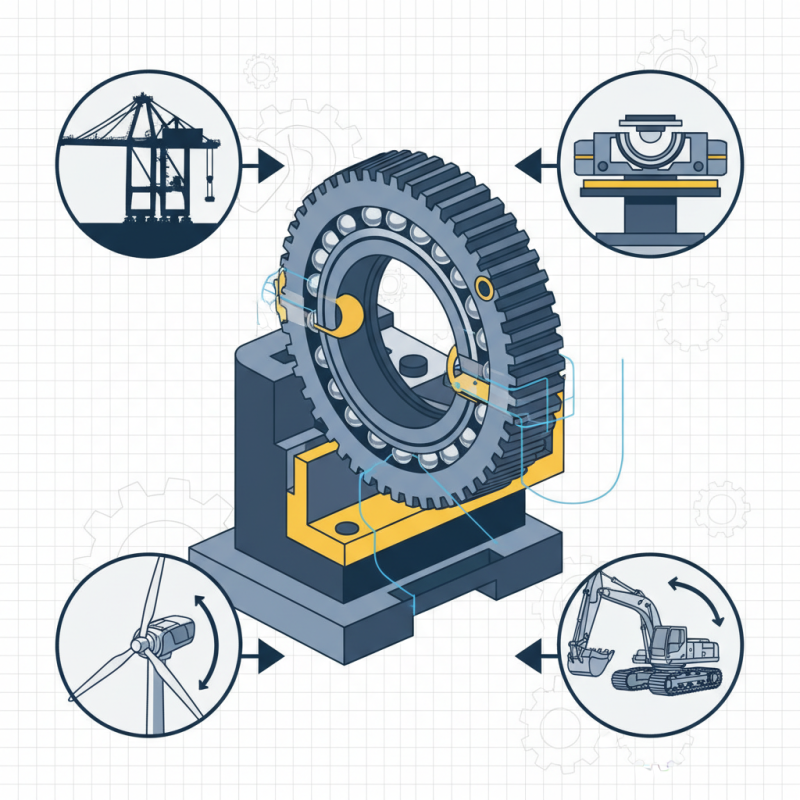

Slewing circle bearings are crucial components in various heavy machinery. They provide support and enable rotational movement between two parts. Commonly found in cranes, excavators, and wind turbines, these bearings can withstand both axial and radial loads. According to the Market Research Future report, the global slewing bearing market is expected to grow at a CAGR of 6.5% through 2025. This growth reflects increasing demand in construction and renewable energy sectors.

Understanding how slewing circle bearings function is essential for their effective application. These bearings consist of an inner and outer ring, with rolling elements between them. When one ring rotates, the rolling elements facilitate smooth movement. For example, construction cranes can rotate 360 degrees, enabling them to cover large areas. The design varies, requiring careful selection based on the application's specific load and speed requirements.

However, the reliance on these bearings raises concerns. Failure can lead to costly downtime and safety hazards. Regular maintenance is critical but often overlooked. Many operators underestimate the importance of ensuring proper lubrication and alignment. Neglecting these factors can compromise performance, leading to significant operational challenges. The need for better training and awareness in proper maintenance practices remains a pivotal point of reflection in the industry.

Slewing circle bearings are crucial in many heavy machinery applications. They consist of several key components that work together. The main parts include inner and outer rings, rolling elements, and a cage. The inner and outer rings serve as the bearing’s structure. They maintain alignment and provide stability during operation.

The rolling elements, often balls or rollers, sit between the rings. They reduce friction as the bearings rotate. This allows for smooth movement of heavy equipment. The cage keeps the rolling elements evenly spaced. It ensures they don’t clump together, which could lead to failure.

When these components wear out, issues arise. A worn surface can lead to increased friction. This may cause overheating and potential breakdowns. Regular inspection and maintenance are essential. Inspect for signs of wear or damage. Addressing these early can prevent costly downtime. This attention to detail is critical for ensuring the reliability of slewing circle bearings in demanding environments.

The chart below illustrates the distribution of various components within a slewing circle bearing by percentage.

Slewing circle bearings play a crucial role in machinery. They support and allow rotational movement. Often found in cranes, excavators, and wind turbines, these bearings facilitate heavy loads with minimal effort. Their design typically features a ring with balls or rollers, enabling smooth motion.

In machinery, slewing circle bearings enable precise movement. They connect stationary and rotating parts. This interaction allows cranes to safely lift and rotate heavy objects. As the load shifts, it's essential for the bearing to maintain stability. However, issues can arise if not properly maintained. Dust and debris can accumulate, leading to friction. Over time, this can increase wear.

Operators need to monitor the condition of these bearings. Regular inspections are key to prevent failures. Paying attention to any unusual noises or vibrations can help detect problems early. Awareness and proactive management can enhance performance significantly. Maintenance is often overlooked, but it’s vital for longevity.

Slewing circle bearings play a vital role across various industries. These components allow heavy loads to rotate smoothly. They are essential in cranes, excavators, and wind turbines. The global market for slewing bearings is projected to grow significantly. Reports indicate a growth rate of 5.1% from 2021 to 2028.

In construction, slewing circle bearings enable precise movements. For example, tower cranes rely on these bearings for stability and mobility. They ensure that heavy materials can be lifted and maneuvered efficiently. However, the maintenance of these bearings can sometimes be overlooked. Regular inspections are crucial to prevent unexpected failures.

In the renewable energy sector, wind turbines use slewing bearings for their blades. This application allows blades to rotate to capture wind effectively. A study highlighted that about 30% of turbine downtime is linked to bearing issues. This is an area needing improvement. Enhanced lubrication and timely maintenance could mitigate these challenges and improve overall efficiency.

Slewing circle bearings are crucial in heavy machinery. Proper maintenance is key to prolonging their lifespan. Regular inspections help identify wear and tear. Look for signs like unusual noises or lubrication leaks. These can signal potential issues that need addressing.

Lubrication plays a vital role in the bearing's performance. Using the right lubricant is essential. Incorrect lubrication can lead to increased friction and wear. Ensure that the bearings are cleaned and re-lubricated as recommended. Scheduled maintenance checks can help prevent breakdowns.

Keeping the bearing area clean is important. Dirt and debris can lead to premature failure. Make it a habit to check for accumulated grime. A clean workspace promotes better performance. Also, be mindful of load limits. Overloading can strain the bearing, causing long-term damage. Taking these simple steps can enhance the longevity of slewing circle bearings.

| Dimension | Description | Maintenance Tip |

|---|---|---|

| Inner Diameter | The internal opening of the slewing bearing, which fits around the shaft. | Ensure regular lubrication to prevent wear. |

| Outer Diameter | The external dimension of the bearing, determining its fit into the housing. | Inspect for corrosion and damage to prolong life. |

| Width | The thickness of the bearing, affecting load capacity. | Keep the bearing clean to avoid debris buildup. |

| Load Capacity | Maximum weight the bearing can handle. | Do not exceed the specified load ratings. |

| Speed Rating | The maximum allowable speed of operation. | Monitor speed and adjust workload accordingly. |