+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

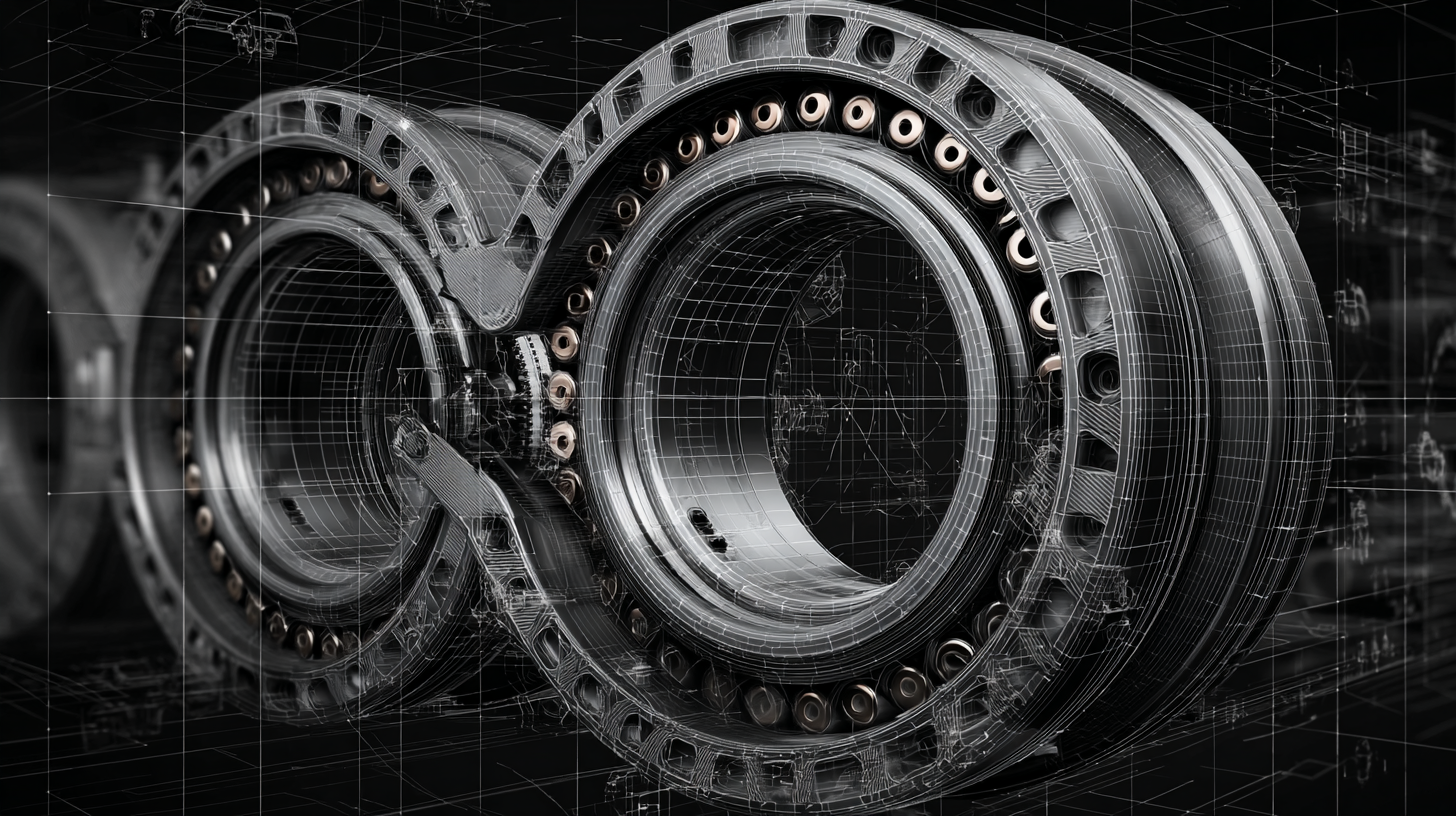

In the rapidly evolving world of heavy machinery, the importance of swing bearings cannot be overstated. These critical components have emerged as pivotal in enhancing the performance of various applications, from excavators to cranes. According to a recent report by Research and Markets, the global swing bearing market is projected to reach USD 2.5 billion by 2026, driven by growing infrastructure developments and a rising demand for efficient machinery. Understanding the essentials of swing bearing design is crucial for engineers and manufacturers aiming to optimize performance, reduce maintenance costs, and increase the lifecycle of their equipment. This blog will delve into the intricacies of swing bearing design and applications, providing insights into best practices and innovative approaches that can drive success in this indispensable aspect of mechanical engineering.

Swing bearings are crucial components in various heavy machinery applications, providing the necessary support and rotation capabilities for equipment such as excavators, cranes, and wind turbines. This blog will delve into the different types of swing bearings, highlighting their unique features and applications based on industry reports.

Swing bearings are crucial components in various heavy machinery applications, providing the necessary support and rotation capabilities for equipment such as excavators, cranes, and wind turbines. This blog will delve into the different types of swing bearings, highlighting their unique features and applications based on industry reports.

One of the predominant variants of swing bearings is the roller-type bearing, which offers enhanced load-bearing capacity and reduced friction. According to a report by MarketsandMarkets, the adoption of roller swing bearings in construction machinery has increased by approximately 15% over the last three years, attributed to their robustness and longevity in demanding environments. Additionally, slewing rings, which allow for precise rotational movements, have gained popularity, especially in robotics and automation, with a market growth projected at over 10% annually through 2025.

Another significant type is the gear-driven swing bearing, which integrates a gear mechanism to facilitate rotation. This type has been particularly favored in offshore wind turbines, where the need for reliable and durable components is paramount. A study from Grand View Research estimates that the use of gear-driven swing bearings in renewable energy applications could surge due to the industry's push towards more efficient and sustainable technologies. These advancements are paving the way for innovations in swing bearing designs that meet the evolving demands of various sectors.

When designing swing bearings for machinery, several key factors must be considered to ensure optimal performance and longevity. One crucial aspect is the load-bearing capacity of the bearing, which should be assessed based on the specific application and environmental conditions. Engineers need to evaluate both dynamic and static loads that the bearing will encounter during operation. Additionally, the material selection plays a vital role in enhancing durability; high-quality steels or specialized composites can resist wear and corrosion.

Tips: Always consult manufacturer specifications for load ratings and consider a thorough failure mode analysis during the design phase. This can help identify potential weak points before they become issues in operational settings.

Another important consideration is the lubrication system. Proper lubrication is essential for reducing friction and wear, leading to smoother operation and extending the life of the bearing. It's important to choose an appropriate lubricant that can withstand the operating temperature and conditions specific to the application.

Tips: Implement a regular maintenance schedule that includes lubrication checks and replacements to sustain bearing performance over time. Also, consider using sealed bearings to reduce contamination from dust and debris.

| Design Parameter | Importance | Applications | Material Options | Maintenance Frequency |

|---|---|---|---|---|

| Load Capacity | Critical for performance under heavy loads | Excavators, cranes | Carbon steel, stainless steel | Every 6 months |

| Operating Temperature | Affects material choice and performance | Mining equipment, wind turbines | Bronze alloys, polymers | Yearly |

| Environmental Conditions | Critical for longevity and reliability | Construction equipment, agriculture | Polymer composites, special coatings | Bi-annual |

| Rotational Speed | Impacts design and material choice | Robotics, automotive | Ceramics, high-performance steels | Monthly |

| Alignment Tolerances | Essential for minimizing wear | Transport machinery, industrial equipment | Steel, aluminum | Quarterly |

Swing bearings are crucial components widely utilized across various industries, including construction, marine, and renewable energy. In construction, swing bearings enable smooth rotation in excavators and cranes, allowing for precise material handling on job sites. They are designed to support heavy loads while maintaining stability, which is essential for the safety and efficiency of construction operations.

In the marine industry, swing bearings play a vital role in enhancing the maneuverability of ships and vessels. They facilitate the rotation of key equipment such as cranes, which are essential for loading and unloading cargo. Similarly, in the offshore wind sector, swing bearings are imperative for the operation of turbines. Their ability to handle dynamic loads and harsh environmental conditions makes them an indispensable part of turbine assemblies, ensuring high performance and reliability.

**Tips:** When selecting swing bearings, consider factors such as load capacity, environmental conditions, and maintenance requirements. Routine inspections are important to detect wear and prevent failures, extending the lifespan of these components. Additionally, collaborating with manufacturers for custom designs can optimize performance for specific applications.

Swing bearings are crucial components in heavy machinery, particularly in applications such as excavators and rotary cranes. To ensure optimal performance and longevity of swing bearings, proper maintenance practices are essential. According to a report by the International Journal of Engineering and Technology, inadequate maintenance can reduce the lifespan of swing bearings by nearly 50%, leading to costly downtimes and repairs.

Regular inspection and lubrication are key maintenance practices that significantly enhance the performance of swing bearings. The American Society of Mechanical Engineers (ASME) recommends lubricating swing bearings at least every 250 hours of operation, or more frequently in harsh environments. In fact, studies show that proper lubrication can increase bearing life by up to 60%. Furthermore, implementing condition monitoring techniques, such as vibration analysis and temperature checks, can help in identifying potential failures before they escalate, contributing to more efficient maintenance schedules and reduced operational costs.

Lastly, operators must also be aware of the environmental conditions affecting swing bearings. Dust, debris, and moisture can lead to premature wear and damage. According to a survey by the Equipment Maintenance Magazine, 30% of machinery failures are linked to environmental factors. Hence, utilizing protective covers and ensuring a clean operational environment can play a significant role in the longevity and efficiency of swing bearings.

When evaluating swing bearing materials, it's essential to consider the specific applications and performance requirements. Various materials, such as steel, bronze, and composite polymers, offer distinct advantages that can be tailored to different operational environments. For instance, steel swing bearings are known for their strength and durability, making them suitable for heavy-duty applications in sectors like construction and mining. On the other hand, composite materials may provide better corrosion resistance and lower weight, which are advantageous in marine or aerospace applications.

Moreover, the comparative analysis of these materials highlights the trade-offs between weight, strength, and cost-effectiveness. While steel offers robustness, the weight can be a disadvantage in applications where reduced mass is crucial. Similarly, bronze provides excellent wear resistance but may not be as readily available or cost-efficient as modern composite options. As industries evolve, the trend toward innovative materials that enhance performance while reducing environmental impact is increasingly relevant, paralleling developments in other high-tech fields, such as carbon capture technologies. Understanding these dynamics can guide engineers and designers in selecting the most appropriate bearing solutions for their specific needs.