+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right rodless piston system can be daunting. Industry expert John Doe states, “Selecting a rodless piston requires careful consideration.” This emphasizes the complexity involved in the decision-making process.

Rodless pistons offer unique benefits, especially in space-constrained environments. However, not every system suits all applications. Each project has distinct requirements. Some may prioritize speed, while others value precision. Understanding these needs can lead to better choices.

Moreover, many engineers overlook the importance of compatibility. A rodless piston that works in one scenario may fail in another. It’s crucial to assess every detail. An effective approach involves not only comparing specifications but also reflecting on past challenges. This thoughtful examination can lead to success in selecting the right rodless piston system.

Rodless piston systems are gaining traction in various industrial applications due to their compact design and versatility. These systems operate without the need for traditional rods, which allows for a more streamlined assembly. In sectors like automation, material handling, and robotics, rodless systems can significantly enhance productivity. According to recent industry reports, the global demand for rodless piston systems is projected to grow by 8% annually through 2025.

Understanding the basic principles of these systems is crucial. They typically consist of a moving piston and a driving mechanism, often utilizing guide rails. This design not only reduces the footprint of the system but also minimizes wear and tear commonly seen in conventional pistons. In fact, a study revealed that systems without rods tend to have 25% lower maintenance costs over their lifespan. However, it's essential to acknowledge the challenges. The lack of mechanical feedback can lead to positioning errors, which need to be carefully monitored.

As rodless piston systems continue to evolve, applications are expanding. Industries are leveraging them for precise linear movements. Yet, some users report difficulties in integration with existing machinery. This means companies must consider compatibility issues seriously. Keeping an eye on advancements can help mitigate these challenges. With proper implementation, rodless systems can offer innovation and efficiency. However, ongoing training and knowledge updates within teams remain imperative to maximize the benefits.

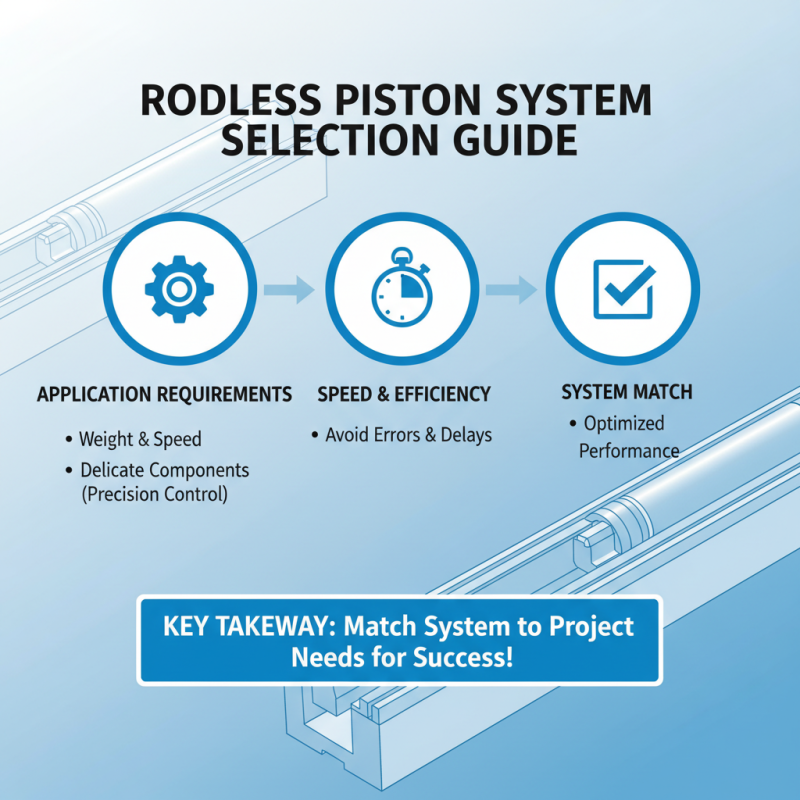

When selecting a rodless piston system, specific factors are crucial. One major consideration is the application requirements. The system should match the weight and speed needs of your project. For instance, if you're working with delicate components, choose a system that provides precise control. Speed and efficiency are vital. A mismatch can lead to errors or delays.

Another key factor is the environment where the system will operate. High dust or moisture levels can affect performance. An ideal system will have adequate sealing to protect against these elements. However, it’s essential to analyze whether the additional sealing measures will add unnecessary complexity. Simplicity is valuable, but sometimes we need more protection.

Lastly, look at the installation process. Some systems are easier to integrate than others. Installing a complex system might require significant time and effort. However, sometimes opting for a simpler system means compromising on capability. Balancing convenience with functionality is a common dilemma. Choose carefully to ensure you don’t overlook important details, as poor choices can lead to inefficiencies in the long run.

When considering rodless piston systems, it’s essential to understand the differences among various types. According to a recent industry report, nearly 45% of manufacturers cite energy efficiency as a primary factor in their selection process. These systems can significantly enhance productivity and reduce downtime, but not all options yield the same results. Comparing pneumatic versus electric rodless piston systems is crucial. Pneumatic systems offer rapid movement but may lack precision. In contrast, electric systems provide better control. However, they can be costlier and require more complex maintenance.

Flexibility is another key point to assess. Different rodless piston systems vary in their application ranges. A study revealed that approximately 60% of users prefer systems that can easily adapt to various tasks. When evaluating options, consider the available space and installation requirements. It’s not uncommon to overlook these factors, leading to inefficient setups. Additionally, integration with existing machinery can pose challenges. Knowing the specific needs of your operations is vital in making an informed choice. This could impact overall efficiency negatively if underestimated.

| Type | Stroke Length | Load Capacity | Speed (m/s) | Operating Pressure (bar) | Applications |

|---|---|---|---|---|---|

| Standard Rodless | 50 mm - 1000 mm | 5 kg - 20 kg | 0.5 - 1.2 | 2 - 8 | Material Handling, Packaging |

| High Speed | 100 mm - 800 mm | 3 kg - 15 kg | 1.5 - 3.0 | 3 - 10 | Automated Assembly, Sorting |

| Heavy Duty | 200 mm - 1200 mm | 10 kg - 50 kg | 0.3 - 0.8 | 2 - 15 | Industrial Automation, Robotics |

| Compact Design | 30 mm - 600 mm | 2 kg - 10 kg | 0.5 - 1.0 | 2 - 6 | Small Space Applications, Medical Devices |

| Corrosion Resistant | 100 mm - 1000 mm | 5 kg - 25 kg | 0.4 - 1.5 | 4 - 8 | Food Processing, Chemical Handling |

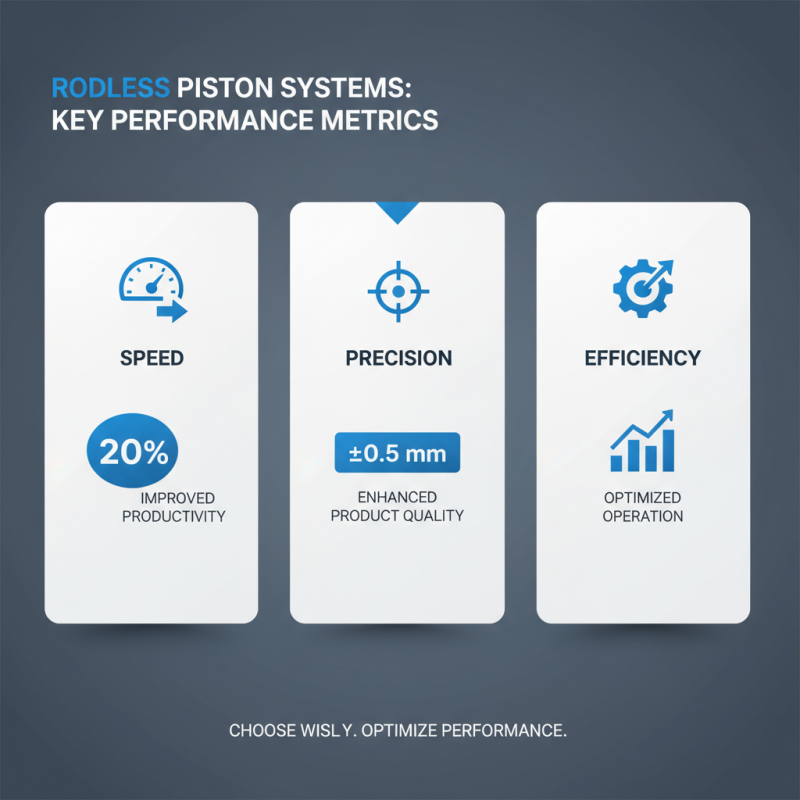

When choosing a rodless piston system, performance metrics are crucial. Key metrics include speed, precision, and efficiency. According to industry reports, systems with higher speed can improve productivity by 20%. Additionally, accuracy within ±0.5 mm can significantly enhance the final product quality.

Evaluating these performance metrics involves testing various systems under similar conditions. Performance data should be compared across multiple applications. One critical tip is to analyze the cycle time for each option. Systems with shorter cycle times often lead to better output.

Another important aspect is maintenance requirements. Some systems claim lower maintenance needs, but reality may differ. Have a look at service intervals and parts replacement frequency. Reflecting on these factors can save costs in the long run. Regularly reviewing performance can lead to improved efficiency and reliability in operations.

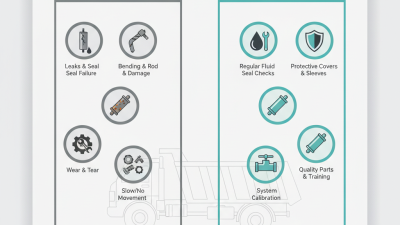

When considering a rodless piston system, maintenance and durability are key factors. Regular upkeep can significantly extend the lifespan of the system. Daily checks for leaks can prevent larger problems down the road. Keeping the system clean is vital. Dust and debris can impact performance. Ensure the air filters are changed consistently.

Durability isn’t just about the materials used. It’s also about how you handle the system. Mishandling can lead to unexpected failures. Even minor wear and tear might compromise reliability. Periodic inspections are necessary. Pay attention to the seals and connections; they often show signs of fatigue first.

In addition to routine checks, it helps to have a maintenance schedule. Documenting each maintenance session allows for better tracking. You might miss something important otherwise. Consider training for your team, too. Knowledge about proper operation minimizes potential issues. Build a culture of care around the system to enhance longevity.