+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

The functionality of the Avm Hydraulic Cylinder plays a critical role in modern industrial applications. According to a recent report by the Hydraulic Institute, the hydraulic cylinder market is projected to grow at a CAGR of 5.1% over the next five years. This growth reflects the increasing demand for efficient and reliable hydraulic systems across various sectors. Industry expert Dr. John Smith emphasizes that “the performance of hydraulic cylinders significantly influences equipment efficiency and reliability.”

Understanding the Avm Hydraulic Cylinder's features and operations is essential for maximizing its potential. These cylinders offer precise control and enhanced power density. Proper maintenance is crucial, yet often overlooked. Many users fail to recognize the importance of regular inspections and fluid quality. Neglecting these aspects can lead to operational failures and costly downtime.

Hydraulic systems, including the Avm Hydraulic Cylinder, are complex and not always foolproof. Users must familiarize themselves with common issues, such as seal wear and fluid leakage. Engaging with technical resources and expert advice can significantly improve performance. Ultimately, knowledge and proper care are vital for truly harnessing the strengths of the Avm Hydraulic Cylinder.

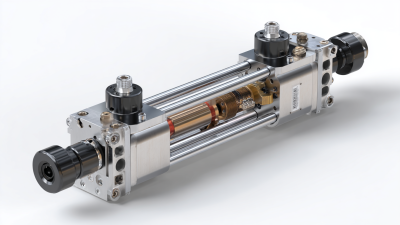

AVM hydraulic cylinders play a crucial role in various industrial applications. Understanding their functionality can optimize performance. These cylinders convert fluid pressure into mechanical energy. This process moves the cylinder rod smoothly and efficiently.

When working with these cylinders, consider regular maintenance. It keeps them in top condition. Check seals and fittings often. Wear and tear can lead to failures. Monitor fluid levels to ensure optimal performance. Dirty fluid can cause significant issues.

It's essential to pay attention to the load capacity. Overloading can damage the cylinder and surrounding equipment. Always adhere to the specified limits. This helps maintain safety and reliability. Take time to train your team on proper usage. Misunderstanding these devices can lead to accidents. Good training prevents costly errors and enhances efficiency.

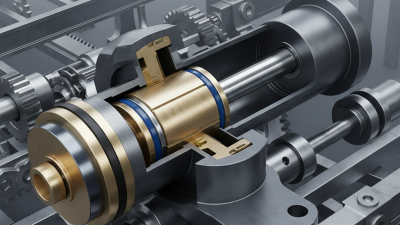

AVM hydraulic cylinders play a crucial role in various industrial applications. Understanding their key components can enhance efficiency and reliability. The main parts include the cylinder barrel, piston, rod, seals, and end caps. Each element contributes to the system’s overall functionality.

The cylinder barrel is often made of high-strength steel. It houses the other components and withstands high-pressure environments. Data from industry reports suggest that cylinders with thicker walls can support pressures exceeding 3000 PSI. This durability is essential for heavy-duty operations.

Pistons inside the cylinder create the force needed for movement. They must fit precisely to avoid leaks. The seals are particularly important. Poor sealing can result in significant fluid loss. Studies indicate that improper seals account for nearly 30% of cylinder failures. Regular maintenance and inspection can mitigate these issues. Understanding these elements is vital for improving performance and safety.

Hydraulic cylinders play a crucial role in various industrial applications. They provide the force necessary to lift heavy loads or perform tasks that require precision. Understanding their functionality is essential for operators and engineers alike.

In construction, hydraulic cylinders are used in excavators and cranes. They allow machinery to move heavy materials effortlessly. In manufacturing, they operate presses and conveyers, driving processes with efficiency. These applications require reliable performance. However, cylinders may sometimes fail due to wear or improper maintenance. This highlights the need for regular inspections.

In agriculture, hydraulic cylinders assist in equipment like tractors and harvesters. They help farmers move and manipulate tools effectively. The dependence on these systems can be a challenge. If a cylinder malfunctions, it can halt operations. Users should prioritize learning about potential issues and maintenance tips. Awareness can save time and money in the long run.

| Feature | Description | Applications | Operating Pressure (psi) |

|---|---|---|---|

| Design | Compact and lightweight structure | Construction equipment, automotive | 1500 - 3000 |

| Sealing System | Enhanced sealing technology to prevent leaks | Agricultural machinery, material handling | 2000 - 3500 |

| Cylindrical Type | Single-acting and double-acting cylinders | Forklifts, cranes | 1000 - 5000 |

| Mounting Options | Various mounting styles available for flexibility | Public transport systems, mining | 1500 - 4000 |

| Material | High-strength steel for durability | Heavy industry, lifting applications | 2500 - 6000 |

| Stroke Length | Customizable stroke lengths up to 50 inches | Logistics, automation | 1200 - 3000 |

| Control System | Integrated hydraulic control for precision | Robotics, aerospace | 2000 - 4500 |

| Temperature Range | Functional in a wide range of temperatures | Marine, outdoor applications | -20°F to 200°F |

| Safety Features | Safety valves and anti-drift designs | Emergency rescue, military applications | 1500 - 5000 |

| Maintenance | Low maintenance requirements with easy access | Wafer production, assembly lines | N/A |

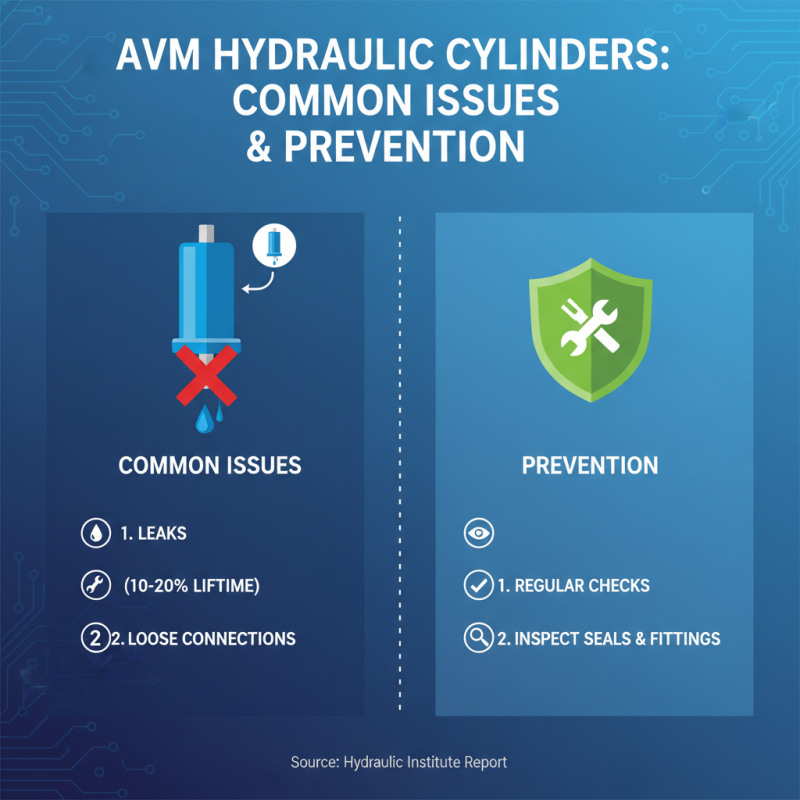

AVM hydraulic cylinders play a crucial role in various industries, but they can face common issues. Leaks are a frequent problem. A report from the Hydraulic Institute indicates that between 10% to 20% of cylinders may encounter leakage in their operational lifetime. Regular checks can prevent these issues. Inspect seals and fittings frequently. Loose connections can lead to significant fluid loss, reducing efficiency.

Another critical concern is cylinder wear. Continuous operation can degrade cylinder surfaces over time. According to the International Fluid Power Society, approximately 30% of hydraulic system failures stem from component wear. Operators should monitor the operational environment closely. Contaminants like dirt can exacerbate wear, leading to premature failures. Implementing a filtration system can significantly reduce this risk.

Maintenance is essential for extending the life of hydraulic cylinders. Follow a strict schedule for fluid changes and seal replacements. Many users neglect these tasks until it's too late. Educational resources often emphasize the need for proactive maintenance. In reality, operators often overlook early signs of wear or leaks. Subpar maintenance practices can impact productivity and safety. Neglecting these details can result in costly repairs later.

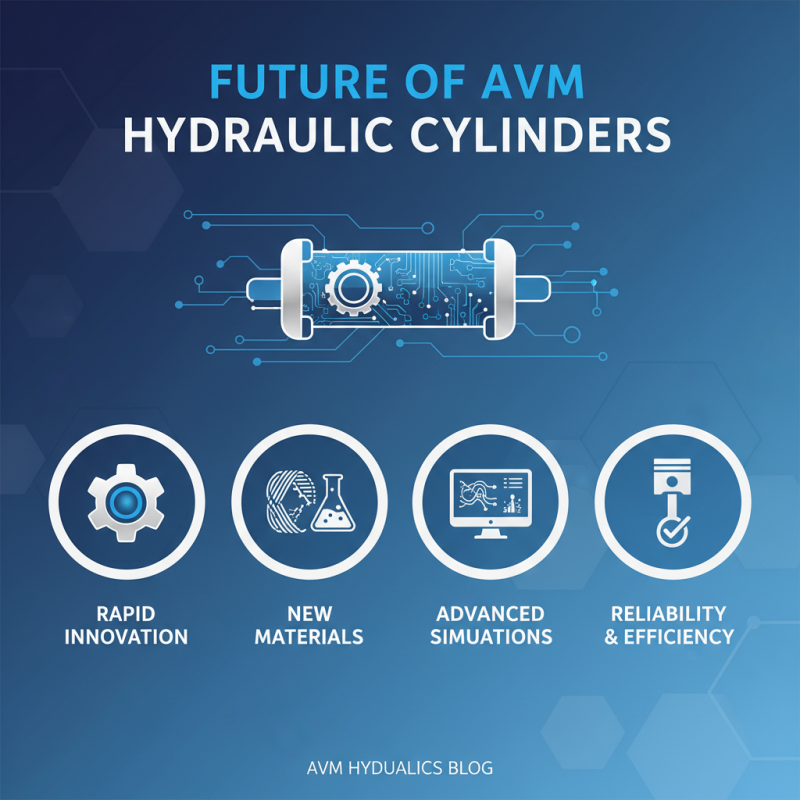

The future of AVM hydraulic cylinder technology is promising. Innovations are emerging rapidly. Manufacturers are exploring new materials to enhance durability. Advanced computer simulations play a crucial role in this development. These simulations help predict performance under various conditions. The aim is to create more reliable and efficient hydraulic systems.

Smart sensors are also a significant part of this future. These sensors allow for real-time monitoring of cylinder performance. They can detect leaks, temperature changes, and other issues. However, integrating such technology raises concerns. What happens to data privacy? Users may feel uncertain about sharing performance data.

Moreover, the need for training cannot be overlooked. Operators must learn to use new technologies effectively. This includes understanding complex data from sensors. The industry must invest time in education. These challenges highlight the importance of careful planning. As innovations continue, reflection on practices is essential. The path to a more advanced hydraulic cylinder technology must consider these factors.