+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

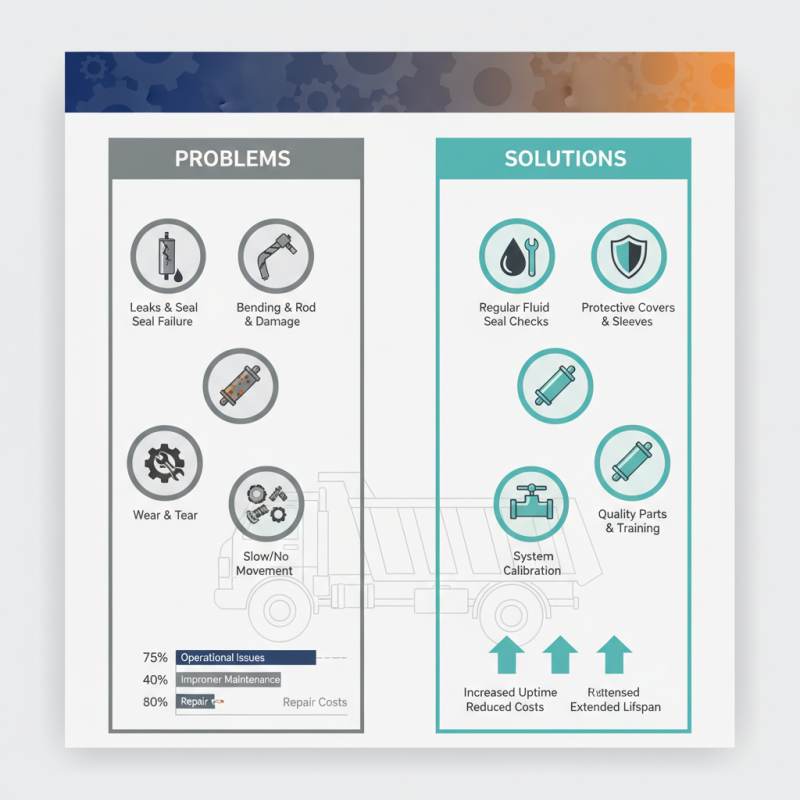

The efficiency and functionality of dump bed cylinders are critical in the heavy-duty vehicle industry, particularly for construction and agricultural applications. According to recent industry reports, approximately 75% of operators experience operational issues with hydraulic systems, with dump bed cylinders being a focal point of concern. These issues not only lead to downtime but can also incur significant repair costs, affecting overall productivity and budget management.

As technology advances, the design and engineering of dump bed cylinders have improved, yet common problems persist due to wear and tear from extensive usage. A study by the Hydraulic and Pneumatic Equipment Association (HPEA) indicates that nearly 40% of hydraulic failures can be attributed to improper maintenance and environmental factors, thereby emphasizing the necessity for operators to be aware of potential malfunctions.

Understanding the top problems associated with dump bed cylinders and their solutions is essential for maintaining efficiency and prolonging the lifespan of these critical components. This guide aims to highlight the most prevalent issues encountered by operators, providing insights and actionable solutions that can enhance performance and reliability in diverse operational settings.

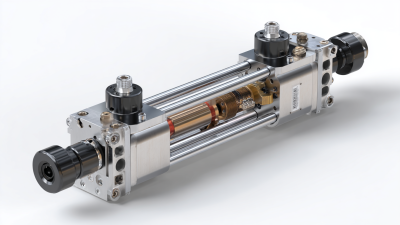

Dump bed cylinders are essential components in heavy-duty vehicles, enabling the efficient lifting and unloading of material. However, they can encounter various issues that hinder performance. One of the most common problems is hydraulic fluid leaks, which can result from worn seals or damaged hoses. According to a report by the International Fluid Power Society, approximately 30% of hydraulic system failures are directly linked to leaks and fluid contamination. Addressing these leaks promptly not only improves function but also extends the lifespan of the cylinder.

Another prevalent issue is cylinder bending or misalignment, which often occurs due to excessive loads or improper installation. A study published by the Society of Automotive Engineers (SAE) indicates that misalignment can lead to a 50% reduction in the life expectancy of hydraulic cylinders. Proper alignment techniques and regular maintenance checks can mitigate this risk and ensure optimal operation. Additionally, operators should routinely inspect the entire hydraulic system for wear and ensure that the dump bed is not overloaded, as adhering to load specifications is critical for maintaining equipment integrity.

Malfunctioning dump bed cylinders can lead to significant operational inefficiencies and safety hazards. Some common symptoms include

slow or erratic movement when raising or lowering the dump bed, unusual noises such as grinding or hissing, and visible hydraulic fluid leaks around the cylinder.

According to industry data, nearly 30% of hydraulic system failures are attributed to issues with the cylinders themselves, highlighting the importance of early detection and maintenance.

Another key indicator of problems with dump bed cylinders is uneven dumping. If the load appears to be unevenly distributed or if the bed doesn’t rise to the expected height, it may signal wear or damage within the cylinder.

Additionally, frequent pressure drops can indicate internal valve issues, which can compromise the efficiency of the entire hydraulic system. Reports suggest that proactive inspection and maintenance can reduce the risk of such failures by up to

50%, ensuring smoother operations and extending the lifespan of the equipment.

Regular monitoring and addressing these symptoms early can save operators time and money, preventing costly repairs and downtime. Keeping a close eye on these warning signs can help maintain optimal performance in dump bed operations.

When troubleshooting problems with dump bed cylinders, a systematic approach can prevent costly downtimes and ensure optimal performance. One common issue is hydraulic fluid leakage, which can lead to reduced lifting capability. According to industry data from the Hydraulic Institute, approximately 20% of hydraulic system failures stem from inadequate sealing mechanisms. To address this, begin by inspecting the cylinder seals and replacing any that show signs of wear or damage. Regular maintenance checks can significantly extend the lifespan of these components.

Another prevalent problem is cylinder sticking, often caused by contamination or insufficient lubrication. Reports from the International Fluid Power Society indicate that contamination is responsible for about 35% of hydraulic failures. To troubleshoot this, ensure the hydraulic fluid is clean and at the proper level, and verify that filters are replaced regularly. For persistent sticking issues, consider performing a complete system flush to eliminate any debris buildup that may interfere with cylinder movement. Following these steps can lead to smoother operation and heightened efficiency in your dump bed systems.

When dealing with dump bed cylinders, several common issues can arise that affect their performance and reliability. One frequent problem is hydraulic fluid leakage, which can lead to inadequate lifting power. To effectively address this, it’s crucial to regularly inspect seals and fittings for any signs of wear or damage. Replacing worn components promptly can prevent further leakage and ensure the hydraulic system functions properly.

Another prevalent issue is cylinder rod bending, often caused by improper loading or excessive weight. To remedy this, operators should be trained in proper loading techniques to distribute weight evenly and avoid overloading. Additionally, adding reinforcement brackets or using stronger materials can enhance the sturdiness of the cylinder. Implementing regular maintenance checks and ensuring that the dump bed operates within its specified limits are essential strategies for preventing and repairing these problems, significantly extending the lifespan of the dump bed cylinder.

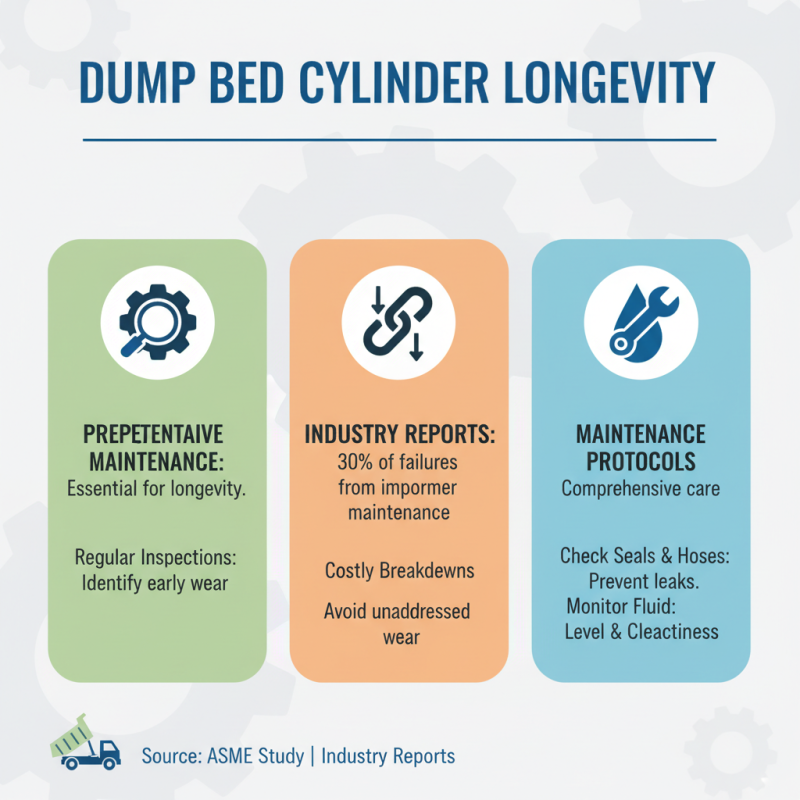

To ensure the longevity of dump bed cylinders, implementing effective preventative maintenance strategies is essential. According to industry reports, regular inspections can identify early signs of wear and tear, which, if unaddressed, could lead to costly breakdowns. A study by the American Society of Mechanical Engineers highlights that about 30% of hydraulic system failures are attributed to improper maintenance practices. This statistic emphasizes the need for comprehensive maintenance protocols that include routine checking of seals and hoses for leaks, as well as monitoring fluid levels and cleanliness.

Furthermore, lubrication is a critical aspect of maintaining dump bed cylinders. Proper lubrication can reduce friction, enhancing performance and extending the life of the cylinder. The Fluid Power Society recommends a lubrication schedule based on operating conditions; for instance, cylinders that are frequently exposed to harsh environments may require more frequent attention. Additionally, keeping the cylinder and surrounding areas clean can prevent contaminants from entering the hydraulic system, which can lead to significant damage over time. By adhering to these maintenance tips, operators can reduce the risk of unexpected failures, therefore ensuring the reliability and efficiency of their dump bed systems.