+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

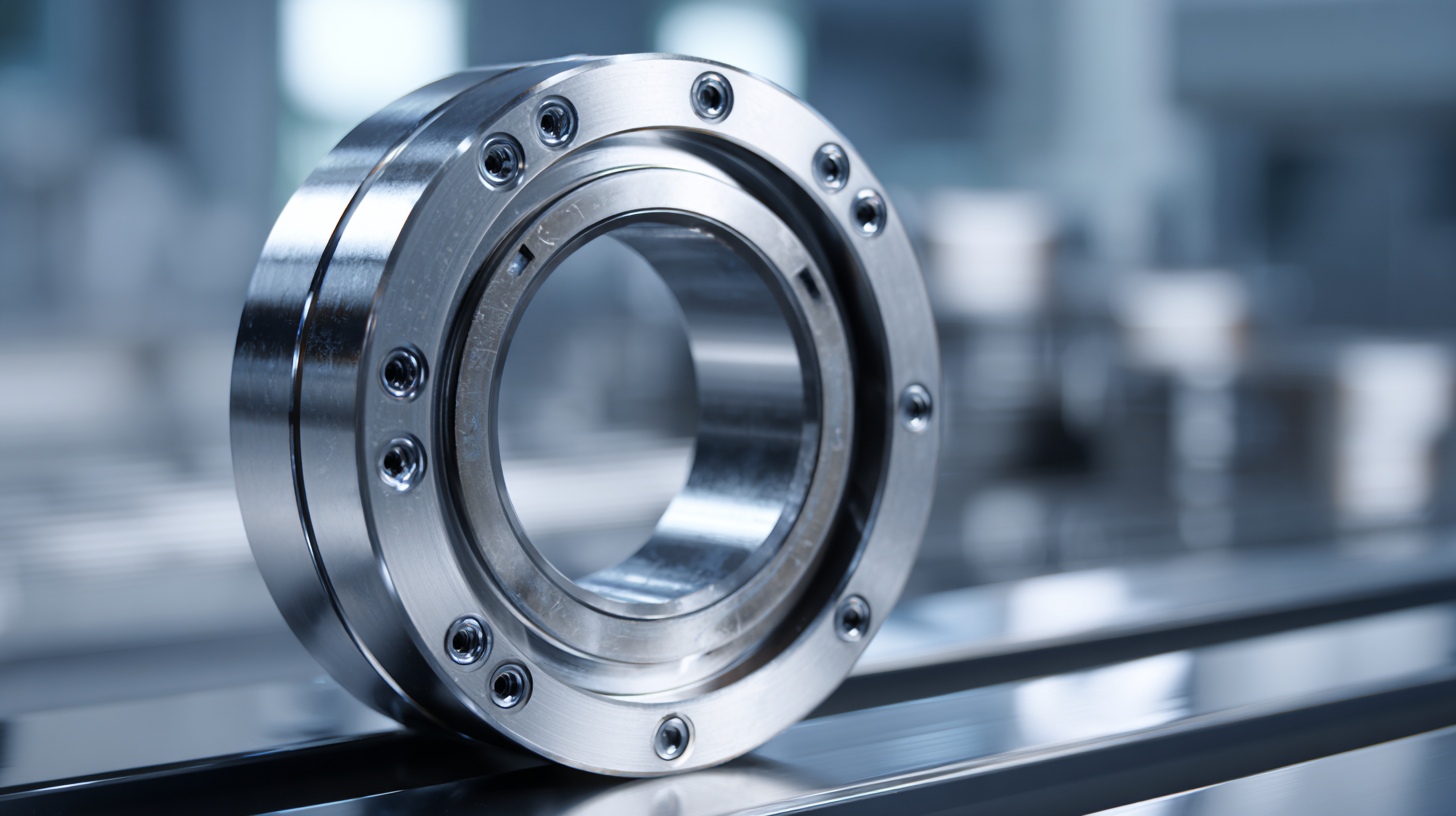

In the evolving landscape of heavy machinery, the selection of reliable components is pivotal for optimal performance and safety. Among these essential parts, the slewing ring bearings emerge as a critical element, facilitating smooth rotation and load-bearing capabilities across various applications. As industries demand more advanced machinery, the market for slewing rings has responded with innovative designs and enhanced materials, positioning them as indispensable for equipment like cranes, excavators, and industrial robots.

This article delves into the top five slewing ring bearings projected to lead the market in 2025, offering insights into their design features, performance metrics, and application suitability. By analyzing market trends and technological advancements, we aim to provide a comprehensive overview that aids manufacturers and engineers in making informed decisions. Whether for construction, mining, or manufacturing sectors, understanding the significance of slewing rings will empower stakeholders to enhance the efficiency and reliability of their machinery.

Slewing ring bearings play a crucial role in the operation of heavy machinery, serving as key components that facilitate the rotation of equipment such as cranes, excavators, and wind turbines. According to a report by Market Research Future, the global slewing bearing market is expected to reach USD 3 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.2% from 2019 to 2025. This growth reflects the increasing demand for improved operational efficiency and load handling capabilities in various industrial sectors.

The importance of slewing ring bearings in heavy machinery cannot be overstated. They are engineered to bear heavy loads and provide high precision, making them indispensable in applications where stability and accuracy are paramount. A study conducted by Research and Markets highlights that the construction and mining sectors are the largest users of these bearings, with their operational demands illustrating the need for robust, reliable bearing solutions. As heavy machinery continues to evolve with technology advancements, slewing ring bearings are expected to incorporate innovations such as integrated sensors for better performance monitoring, further underscoring their significance in enhancing machinery reliability and extending service life.

In 2025, slewing ring bearings are expected to play a pivotal role in the heavy machinery market, with distinct characteristics that enhance their performance. According to a report by Technavio, the global slewing bearing market is projected to grow at a CAGR of approximately 4.5% between 2021 and 2025, driven by increased investments in infrastructure and construction sectors. This growth highlights the importance of selecting the right slewing ring bearings that can withstand harsh operating conditions while providing reliable performance.

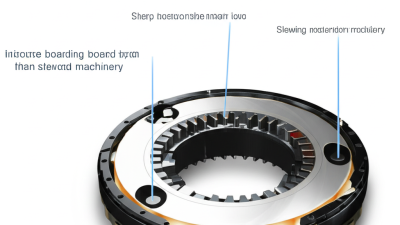

Key characteristics of top slewing ring bearings for 2025 include high load capacity, durability, and precision. The latest advancements in materials, such as advanced composites and heat-treated steel, have enhanced the strength and lifespan of these bearings.

Furthermore, the integration of smart technologies is becoming a trend, with several manufacturers incorporating sensors that monitor load conditions in real-time. According to a recent study by Grand View Research, the demand for slewing ring bearings in cranes and excavators is expected to rise significantly, reflecting a growing need for equipment that can operate efficiently under demanding workloads. These features will ensure that slewing ring bearings remain integral components in heavy machinery applications.

The slewing ring bearings market is poised for significant transformation, driven by evolving industry demands and technological advancements. One of the primary trends is the increasing automation in heavy machinery, which requires slewing ring bearings that can operate reliably under varying loads and conditions. This trend is compelling manufacturers to develop bearings with enhanced durability and performance characteristics, enabling them to withstand the rigors of modern applications.

Another crucial market trend is the growing emphasis on sustainability and energy efficiency. As companies strive to reduce their carbon footprint and enhance operational efficiency, slewing ring bearings are being designed with materials and lubrication solutions that minimize environmental impact. This shift not only aligns with global sustainability goals but also addresses the rising demand from end-users for products that meet stringent regulatory standards. Consequently, innovation in design and materials is expected to play a pivotal role in shaping the future landscape of slewing ring bearings in heavy machinery.

The slewing ring bearings market is experiencing significant growth, driven by the increasing demand for heavy machinery across various industries. In 2024, the global bearings market was valued at USD 46.82 billion, with projections indicating a rise to USD 50.16 billion in 2025 and a substantial leap to USD 97.10 billion by 2030. This surge is largely attributed to advancements in technology and the expanding applications of slewing ring bearings in construction, mining, and renewable energy sectors.

A comparative analysis of leading brands in the slewing ring bearings market reveals distinct strengths and weaknesses. Key players in the industry have been focusing on innovation and efficiency to enhance their competitive edge. For instance, while some brands excel in production capabilities and customization options, others emphasize superior quality and reliability. Understanding these differences is crucial for manufacturers and consumers alike, as it allows them to make informed decisions based on performance, cost-effectiveness, and suitability for specific applications in heavy machinery.

This chart presents a comparative analysis of the market share of the top 5 slewing ring bearings in the heavy machinery sector for the year 2025. The data reflects their estimated market percentages based on various performance metrics.

The slewing ring bearing market has been significantly influenced by recent technological innovations aimed at enhancing performance and reliability in heavy machinery applications. According to a report by MarketsandMarkets, the global slewing bearing market is projected to reach USD 2.6 billion by 2025, growing at a CAGR of 5.2% due to the increasing demand for high-performance machinery across various industries. This growth is largely driven by advancements in manufacturing processes and materials, which have led to the development of slewing ring bearings that offer improved load capacity and durability while reducing maintenance costs.

Innovative designs, such as integrated sensors for real-time monitoring, are also gaining traction. Research by Frost & Sullivan highlights that slewing ring bearings equipped with IoT technology can reduce operational downtime by up to 30%, showcasing the benefits of predictive maintenance. Enhanced lubrication systems, which facilitate smoother operation and longer service life, are being adopted as well, helping manufacturers meet stringent efficiency standards. These advancements not only lead to better performance metrics but also contribute to sustainability goals, as more efficient bearings help in reducing energy consumption in heavy machinery.