+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In the realm of heavy machinery, Backhoe Cylinders play a pivotal role in ensuring efficient operations. As noted by industry expert James Anderson, "A well-functioning Backhoe Cylinder is the backbone of any excavating task; recognizing the signs of wear and tear can save time and money." With various forces at play during operation, these hydraulic cylinders are susceptible to issues that can compromise the performance of a backhoe.

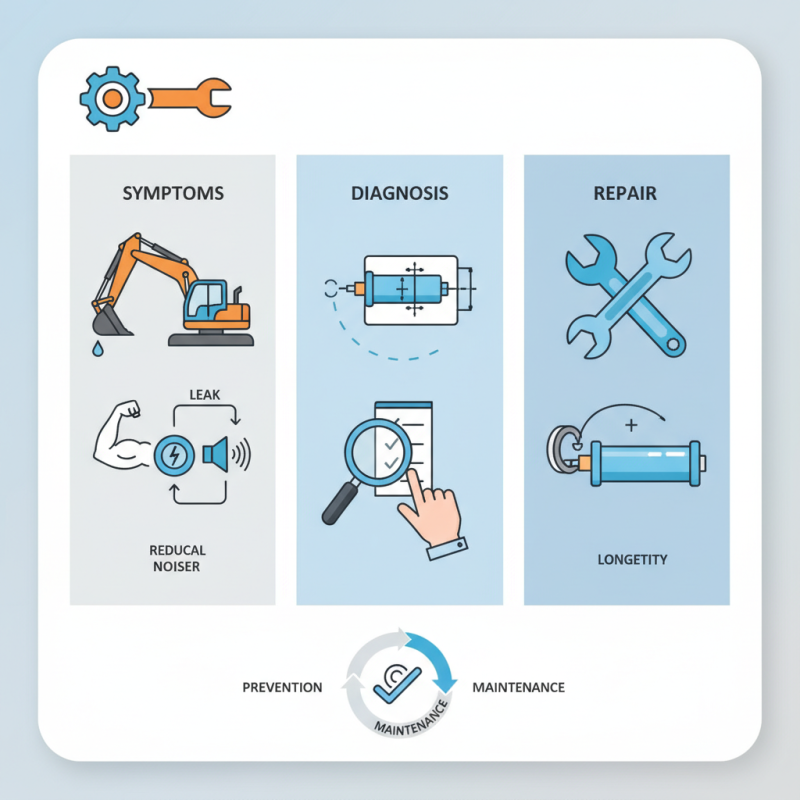

Troubleshooting and repairing Backhoe Cylinder problems are crucial skills for operators and maintenance personnel alike. Recognizing the symptoms of malfunction—such as leaks, reduced power, or unusual noises—can lead to timely interventions that prevent more significant damage. This article delves into effective strategies and best practices for diagnosing and remedying common Backhoe Cylinder issues, ensuring your machinery remains reliable and efficient on the job. By understanding these fundamental principles, you can enhance your operational efficiency and extend the lifespan of your equipment.

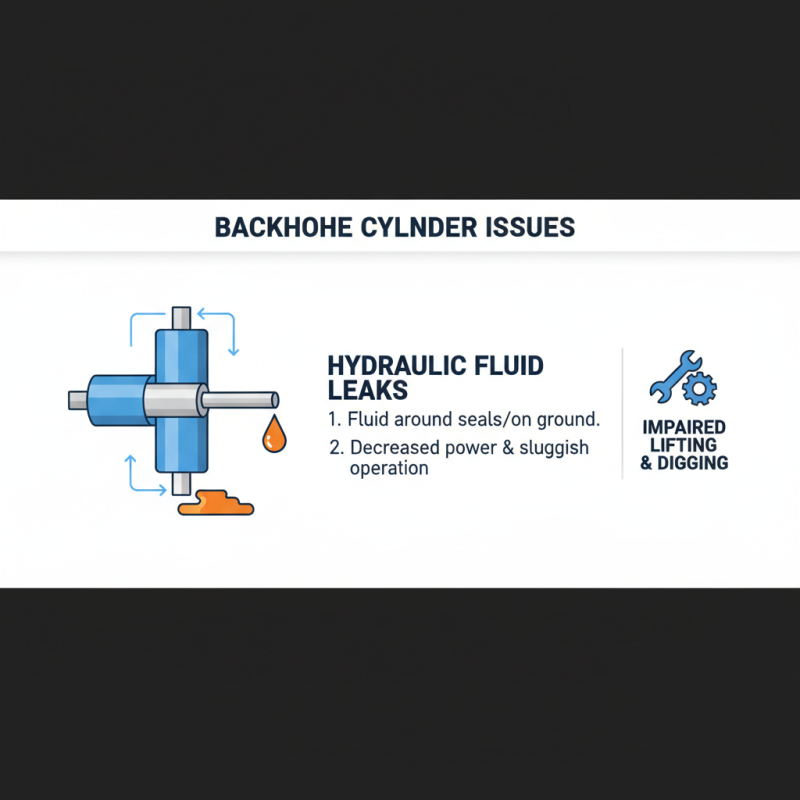

Backhoe cylinders are crucial components that can face various issues, leading to reduced performance or complete failure. One of the most common problems is the presence of hydraulic fluid leaks. These leaks can often be identified by the accumulation of fluid around the cylinder seals or the ground beneath the backhoe. If you notice a decrease in power or sluggish operation, this may also indicate that hydraulic fluid is escaping from the system, which can significantly impair the lifting and digging capabilities of the backhoe.

Another issue often encountered with backhoe cylinders is rod wear. As the cylinder rod makes repeated cycles, it can develop scratches or grooves that affect sealing and operation. Symptoms of rod wear include reduced cylinder stroke or erratic movement, which can be alarming when in operation. Additionally, users may observe increased noise or grinding sounds emanating from the cylinder area. Ensuring that the rod remains properly lubricated and regularly inspecting it for any signs of wear can help mitigate this problem and maintain optimal functionality. Keeping an eye on these symptoms will enable operators to troubleshoot and address backhoe cylinder issues promptly, preventing further complications and costly repairs.

When troubleshooting and repairing backhoe cylinder issues, having the right tools and equipment is crucial for effective results.

Start with basic hydraulic tools such as pressure gauges, hydraulic fluid, and hoses.

A pressure gauge will help you determine if the hydraulic system is operating within the recommended pressure range, while high-quality hoses ensure that there are no leaks or interruptions in the system.

Additionally, a cylinder lifting tool can assist in safely removing the cylinder for inspection and repairs.

In addition to hydraulic tools, a set of hand tools including wrenches, sockets, and screwdrivers will be essential for disassembling and reassembling the cylinder components.

A torque wrench is particularly important to ensure that all fasteners are tightened to the manufacturer's specifications, preventing future issues due to loose fittings.

Don't forget a cleaning kit designed specifically for hydraulic systems, as keeping components free of debris and contaminants can significantly extend the lifespan of the cylinder.

Having these essential tools on hand will make the troubleshooting process smoother and more efficient, allowing for timely repairs and reduced downtime.

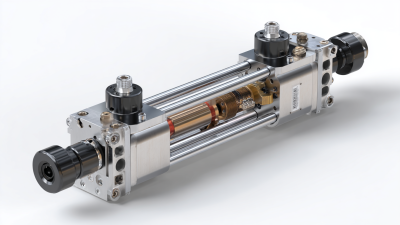

When diagnosing backhoe cylinder problems, it's crucial to follow a systematic approach to identify and address issues effectively. Begin by visually inspecting the cylinders for any obvious signs of damage such as leaks, dents, or corrosion. Check the hydraulic lines for wear and ensure that connections are secure. A thorough examination at this stage can often reveal minor issues that can be easily remedied before they escalate into more significant repairs.

Next, operation under load should be assessed. Engage the backhoe's functions and observe how the cylinders respond. Listen for unusual sounds, such as grinding or knocking, that may indicate internal problems. Pay attention to the speed and power of the cylinder's movement; sluggish response or jerky motion can signal a hydraulic fluid issue or internal wear. If the cylinders exhibit poor performance, verify the hydraulic fluid levels and quality, as contaminated or insufficient fluid can lead to a multitude of problems.

Finally, if initial inspections and tests do not reveal the issue, consider disassembling the cylinder for a closer examination. Inspect the seals, piston, and bore of the cylinder for wear or damage. It's essential to clean all parts thoroughly and replace any faulty components to ensure optimal function. Document each step taken during the troubleshooting process, as this can assist in future repairs and maintenance. By following these steps, you can effectively diagnose and repair backhoe cylinder issues, ensuring your equipment remains reliable and efficient.

| Step | Action | Tools Required | Common Issues Identified |

|---|---|---|---|

| 1 | Inspect the cylinder for visible damage. | Flashlight, inspection mirror | Cracks, bends, leaks |

| 2 | Check for hydraulic fluid leaks. | Oil absorbent pads, cleaning cloths | Low fluid level, puddles of fluid |

| 3 | Test the cylinder operation. | Pressure gauge | Inconsistent movement, unresponsive action |

| 4 | Check seals and O-rings. | Seal kit, screwdriver | Worn seals, improper sealing |

| 5 | Replace any damaged components. | Wrenches, replacement parts | Broken parts, ineffective repairs |

| 6 | Reassemble and refill hydraulic fluid. | Funnel, hydraulic fluid | Air in lines, improper fluid levels |

| 7 | Test the operation of the backhoe. | None needed | Persistent issues, operational failures |

Backhoe cylinders are vital components in heavy equipment, and their failures can lead to decreased performance and increased downtime. Common issues include leaking seals, improper rod alignment, and internal wear. To effectively troubleshoot these problems, it’s essential to conduct a thorough visual inspection first. Look for signs of hydraulic fluid leaks around the cylinder seals, as this can indicate wear or damage. Additionally, check for any visible bending or misalignment of the cylinder rod, which can cause operational issues.

When it comes to repairing backhoe cylinder failures, several techniques can be applied. For leaking seals, replacing the worn seals with new ones is often the most straightforward solution. Ensure to clean the cylinder thoroughly before installation to avoid any debris that could compromise the new seals. If the internal walls of the cylinder are scratched or worn, a honing process might be necessary to create a smoother surface, allowing the new seals to function properly.

Tips: Always ensure that you have the proper tools and protective gear when working on hydraulic systems. Regular maintenance can prevent many common cylinder failures, so consider implementing a routine checkup schedule. This not only extends the lifespan of your equipment but also ensures safety on the job site.

Regular preventative maintenance is critical for prolonging the lifespan of backhoe cylinders and ensuring optimal performance on any job site. According to a report by the Equipment Maintenance Council, proper maintenance practices can reduce equipment downtime by as much as 30%. This emphasizes the importance of regularly checking fluid levels, inspecting for leaks, and ensuring the hydraulic system is functioning correctly. Operators should routinely clean the cylinder rods and check for any signs of wear or damage, as contaminants can lead to premature cylinder failure and costly repairs.

Another key aspect of preventative maintenance is adhering to a consistent inspection schedule. A study published in the Journal of Construction Engineering highlights that routine inspections not only enhance equipment reliability but can also significantly reduce long-term costs associated with unexpected mechanical failures. By making small adjustments or repairs proactively, such as replacing worn seals or tightening fittings, operators can save up to 25% on repair expenses over time. Additionally, maintaining correct hydraulic fluid levels and using filters can prevent contamination, further extending the life of backhoe cylinders.