+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Understanding the functionality and maintenance of outrigger cylinders is crucial for ensuring the safety and efficiency of construction equipment. Outrigger cylinders play a vital role in stabilizing machinery during operations, particularly in cranes and similar equipment. These hydraulic systems not only support the load but also prevent tipping, allowing for safer vertical lifting tasks.

In this article, we will explore essential tips for recognizing the operational principles behind outrigger cylinders and provide guidelines for their upkeep. Proper maintenance is key to maximizing the lifespan and performance of these hydraulic systems, reducing risks of malfunctions, and ensuring operational safety. By delving into the intricacies of outrigger cylinder functionality and maintenance, we aim to equip operators and maintenance personnel with the knowledge necessary to keep their equipment in optimal condition.

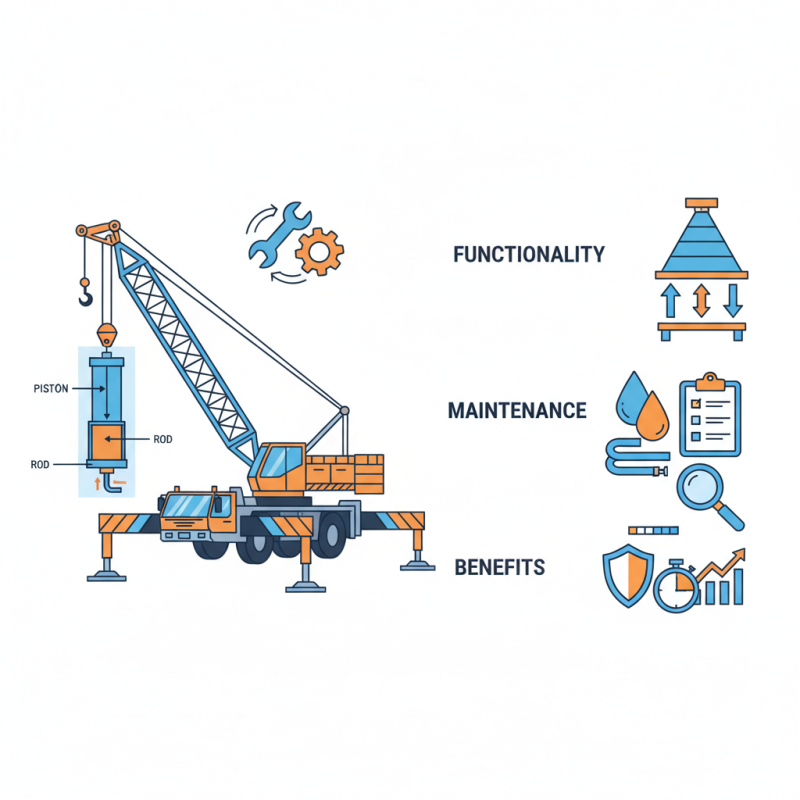

Understanding the functionality of outrigger cylinders is essential for effective equipment operation, particularly in construction and heavy lifting contexts. Outrigger cylinders play a pivotal role in stabilizing machinery by extending and adjusting the base of your equipment. This functionality enhances safety and balance, allowing for more precise work on uneven surfaces. The primary operation involves hydraulic mechanisms that extend the cylinders outward, providing a wider stance for stability during operation.

When it comes to maintenance, keeping an eye on your outrigger cylinders is vital. Regular inspections should include checking for leaks, ensuring the hydraulic fluid levels are adequate, and verifying proper extension and retraction functionalities. An important tip is to clean the cylinders regularly to prevent dirt and debris buildup, which can impair their operation. Additionally, lubricating the moving parts will aid in maintaining smooth functionality and prolonging the life of the hydraulic system.

Another critical tip for understanding outrigger cylinders is to familiarize yourself with their operating limits. Knowing the maximum load they can handle and understanding their limitations in various terrains will prevent accidents and equipment damage. Regular training on safe operating procedures will enhance your team's efficiency and safety measures while using the machinery.

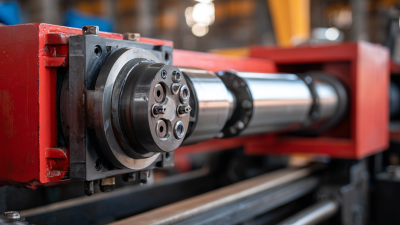

Outrigger cylinders play a vital role in providing stability and support to various heavy equipment, particularly during lifting operations. Understanding the key components of these cylinders is crucial for both functionality and maintenance. The primary parts include the cylinder body, piston, seals, and hoses. The cylinder body houses the hydraulic fluid, which is essential for the extension and retraction of the piston. This movement is what allows the outriggers to extend beyond the width of the equipment, creating a stable base.

The piston, which moves within the cylinder body, is responsible for actuating the outrigger's mechanical operations. Seals are critical in preventing fluid leaks, ensuring the hydraulic system operates efficiently. They must be regularly checked and maintained to avoid any operational failures. Hoses connect the hydraulic fluid reservoir to the cylinders and are vital for transferring fluid under pressure. Regular inspection of these hoses for signs of wear or damage is essential for safe and effective operation. Overall, understanding these components can greatly enhance the productivity and safety of equipment utilizing outrigger cylinders.

| Component | Function | Maintenance Tips | Common Issues |

|---|---|---|---|

| Cylinder Body | Houses the hydraulic fluid and creates force. | Regularly check for wear and corrosion; clean surfaces. | Leaks, rust, premature wear. |

| Piston Rod | Transfers hydraulic energy to lift outrigger. | Inspect for scratches; apply lubricant as needed. | Bending, scoring, leaks from seals. |

| Seals and O-rings | Prevent fluid leaks and maintain pressure. | Inspect and replace as needed; keep surfaces clean. | Fluid leaks, pressure loss. |

| Hydraulic Fluid | Transmits power and lubricates cylinder components. | Regularly check levels and quality; replace as needed. | Contamination, improper viscosity. |

| Control Valves | Regulate fluid flow and cylinder operation. | Check function regularly; clean contacts. | Sticking valves, unresponsive operation. |

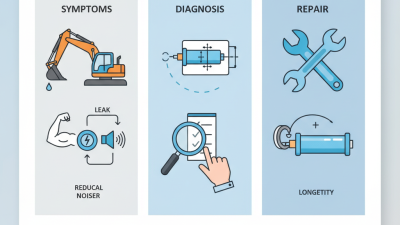

Outrigger cylinders are critical components in heavy machinery, providing stability and support during operation. However, like any mechanical system, they may encounter issues that can hinder performance and safety. Common problems include hydraulic leakage, slow operation, or the inability of the cylinder to extend or retract fully. These issues often arise from wear and tear, improper maintenance, or environmental factors such as exposure to extreme weather conditions. Regular inspection can help identify these problems early, ensuring that any necessary repairs are addressed before they lead to more significant failures.

When troubleshooting outrigger cylinder issues, start by checking the hydraulic fluid levels and look for signs of leakage around the seals and fittings. If the cylinder is slow to respond, it could indicate air trapped in the hydraulic lines or inadequate fluid pressure. Additionally, ensure that the cylinder is free from debris or obstructions that could impede its movement. If the cylinder fails to extend or retract, examine the control valves and the hydraulic pump for proper functionality. Performing routine maintenance such as cleaning and lubricating moving parts can also prolong the lifespan of outrigger cylinders and reduce the likelihood of encountering common issues.

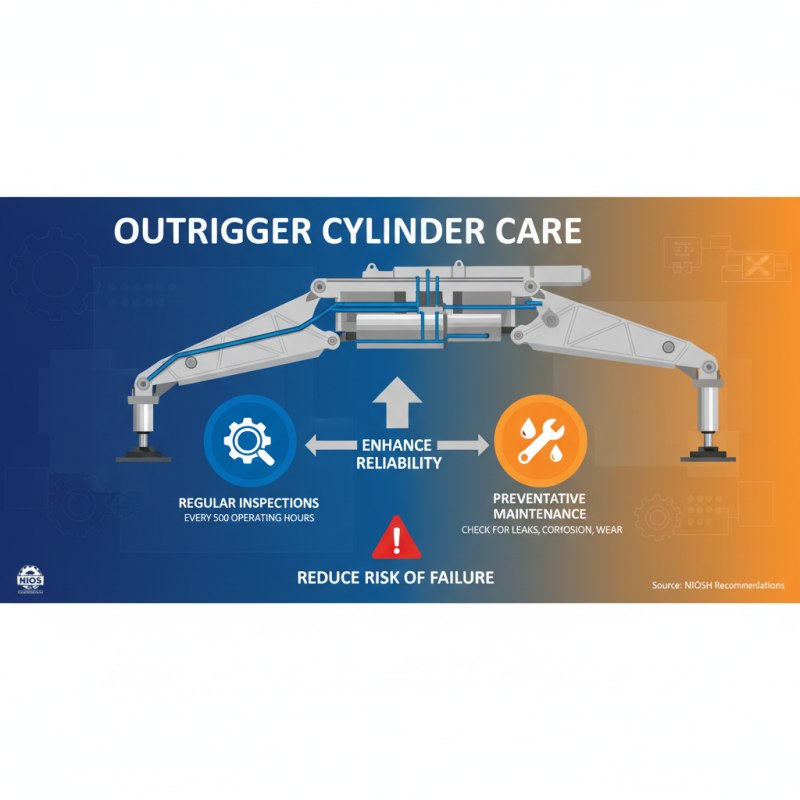

To ensure the longevity and reliability of outrigger cylinders used in construction and heavy lifting, adherence to best practices in maintenance and care is crucial. Regular inspections are vital; the National Institute for Occupational Safety and Health (NIOSH) recommends checking hydraulic systems for leaks, corrosion, and wear every 500 hours of operation. Addressing any issues promptly not only enhances performance but also significantly reduces the risk of failure during critical operations, as hydraulic failure can result in severe accidents.

Moreover, lubrication plays a key role in the maintenance of outrigger cylinders. According to a report by the American Society of Mechanical Engineers (ASME), proper lubrication can decrease friction, extending the life of the cylinder by up to 30%. Operators should follow manufacturer guidelines for lubrication intervals and types to ensure optimal function. Application of high-quality hydraulic fluids is also advised, as it can prevent the degradation of seals and internal components, ultimately safeguarding the investment in equipment.

Lastly, training personnel on the importance of maintenance protocols is essential. The Construction Safety Association has conducted studies showing that projects employing a rigorous maintenance schedule experience a 40% decrease in equipment-related incidents. By prioritizing comprehensive training and regular maintenance checks, teams can ensure their outrigger cylinders operate efficiently and safely, contributing to a more productive work environment.

When working with outrigger cylinders, safety should always be a paramount concern. Outrigger cylinders, commonly used in various heavy machinery applications, provide stability and support on uneven terrain. Before engaging in any task that involves these components, workers must ensure that they are equipped with the appropriate personal protective equipment (PPE), including gloves, helmets, and safety footwear, to minimize the risk of injury.

Proper training and adherence to operating procedures are essential. Operators should be well-trained in the correct use of the outrigger systems, including recognizing the correct extension and retraction processes. Always perform a thorough inspection of the cylinders before use, checking for leaks or signs of wear that could lead to failure. Additionally, one must ensure that the work area is free of obstructions and that all bystanders are at a safe distance to prevent accidents during the operation of machinery that utilizes outrigger cylinders. Prioritizing these safety considerations significantly reduces the risk of mishaps and ensures a safer working environment.