+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

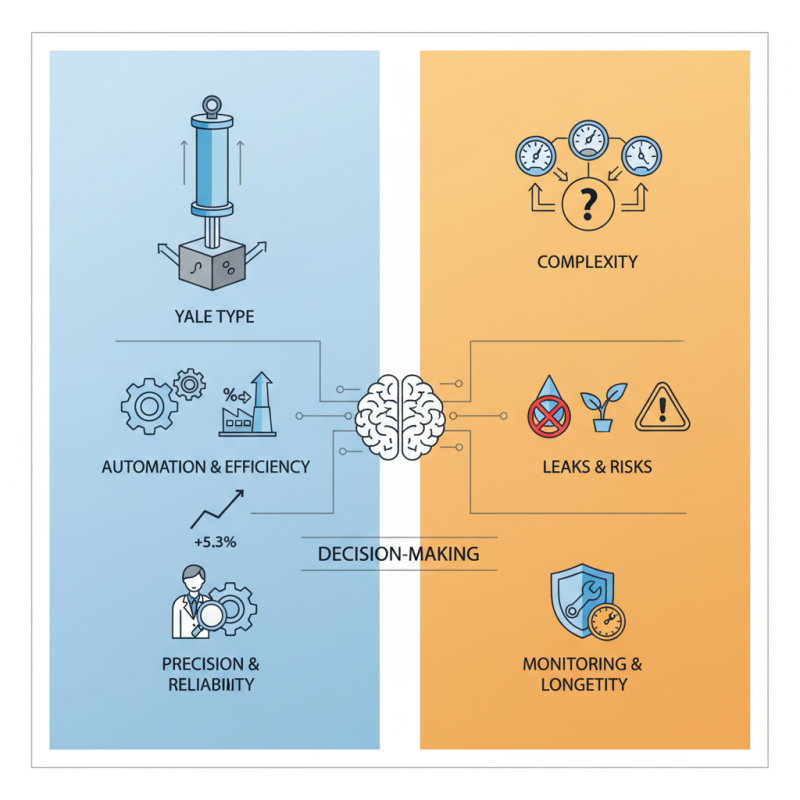

The Yale Hydraulic Cylinder is an essential component in various industries. Its design and functionality play a significant role in optimizing machinery performance. According to a recent industry report by Global Market Insights, the demand for hydraulic cylinders is expected to grow annually by 5.3%, driven by advancements in automation and energy efficiency.

Dr. Emma Thompson, a leading expert in hydraulic systems, emphasizes, “The Yale Hydraulic Cylinder is crucial for precise and reliable operation in heavy machinery.” This highlights its importance in industrial applications. Despite its benefits, understanding the complexities of hydraulic systems can be challenging. Variations in pressure, fluid type, and maintenance practices can greatly affect performance.

Moreover, while the Yale Hydraulic Cylinder offers efficiency, one must also consider potential issues. Hydraulic leaks, for example, can cause environmental harm and safety risks. As such, continuous monitoring and training are vital. Evaluating these factors leads to better decision-making in equipment usage and longevity.

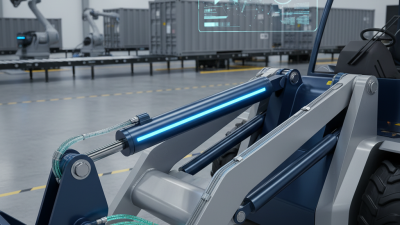

A Yale hydraulic cylinder is a crucial component in various industrial applications. It converts fluid pressure into mechanical force. This device uses hydraulic fluid to create motion. The cylinder consists of a piston and a cylinder barrel. When the fluid enters, it pushes the piston to extend or retract.

These cylinders are designed to handle heavy loads with precision. They can be found in construction, manufacturing, and automotive industries. Their reliable performance allows for smooth operation. However, one must consider maintenance. An overlooked hydraulic line can cause inefficiencies. Proper care ensures longevity and optimal performance.

The technology behind hydraulic systems can seem complex. Yet, the idea is straightforward: use pressure to create movement. Even with advancements, challenges remain. Not all cylinders are equal in quality. Users must understand what they need. This awareness can prevent costly mistakes. A good hydraulic cylinder can make a significant difference. Quality components lead to better outcomes in projects.

Yale hydraulic cylinders play a vital role in various industrial applications. These cylinders are designed to convert hydraulic energy into mechanical energy. Their operation is based on the principles of fluid mechanics. The primary components of these cylinders include the cylinder barrel, piston, rod, and seals. Each component serves a specific purpose, ensuring efficient performance.

The cylinder barrel is the foundation. It houses the piston, which moves when hydraulic fluid is introduced. This movement generates force, which can lift or push a load. The rod extends from the piston and transmits the force to external mechanisms. Seals are essential to prevent hydraulic fluid from leaking. They ensure that the pressure remains stable within the system.

While hydraulic cylinders are effective, they require regular maintenance. Wear and tear on seals can lead to fluid leaks, impacting performance. Over time, dirt and debris can accumulate, affecting the smooth operation of the piston. Ignoring such issues may result in costly repairs. Regular checks on fluid levels and component integrity are crucial for optimal function. Understanding these key components helps in troubleshooting and maintaining hydraulic systems effectively.

Hydraulic cylinders are essential components in many industrial applications. They convert hydraulic energy into linear motion. The working principle relies on hydraulic fluid, which provides force and movement. When pressurized fluid enters the cylinder, it pushes the piston. This creates motion in the rod attached to the piston. According to a report by the International Society for Automation, hydraulic cylinders can produce forces exceeding 150 tons with precision and reliability.

The efficiency of these systems can be improved by understanding fluid mechanics. Specific designs enhance the flow rate and reduce pressure losses. A study from the Fluid Power Journal highlighted that optimal cylinder design can increase performance by 20%. However, poor maintenance can lead to leaks or reduced efficiency. Operators must monitor seals and fluid levels regularly to avoid costly downtimes. Simple checks can extend the lifecycle of hydraulic cylinders, but many overlook these tasks.

While hydraulic cylinders offer remarkable power, they also present challenges. For instance, the danger of hydraulic shock can damage components. It occurs when fluid flows rapidly, creating pressure spikes. Understanding the potential pitfalls is crucial for safety and efficiency. Regular training for personnel can minimize risks and improve operation consistency. Knowledge gaps often lead to mistakes, highlighting the need for continuous learning in industry best practices.

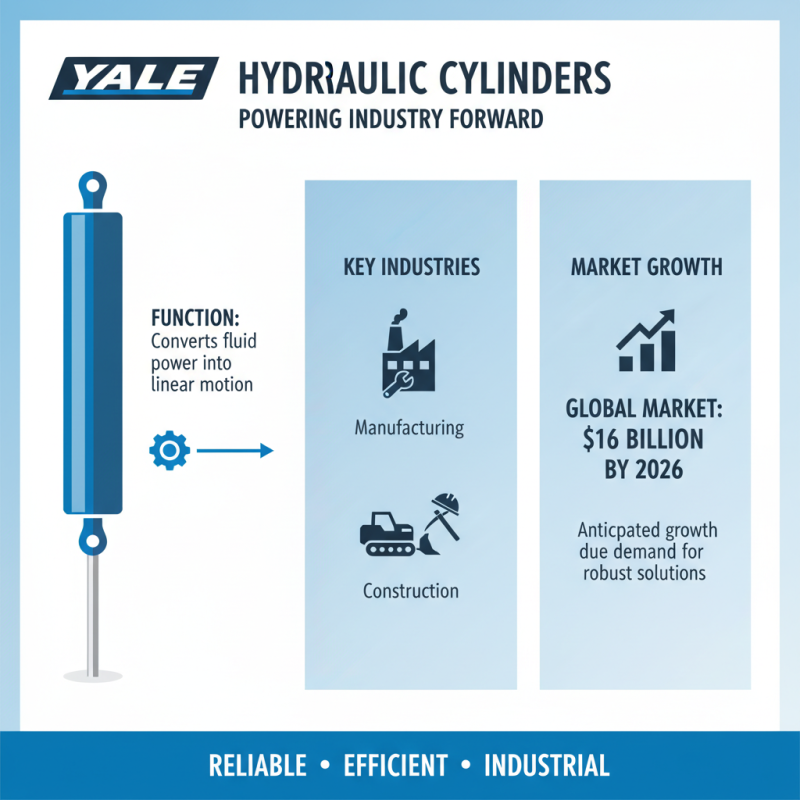

Yale hydraulic cylinders play a vital role in various industries. Their primary function is to convert fluid power into linear motion. They are used in manufacturing, construction, and mining sectors. Reports show that the global hydraulic cylinder market is anticipated to reach $16 billion by 2026. This growth indicates a rising demand for robust hydraulic solutions.

In construction, these cylinders power heavy machinery. They lift and move massive loads efficiently. Equipment like excavators relies on their strength. For mining operations, they provide precise control in harsh environments. However, maintenance often falls short. Regular inspections can prevent costly downtimes.

Tips: Always monitor fluid levels. A low level can lead to cylinder failure. Additionally, ensure seals are intact to avoid leaks. In manufacturing, inconsistent hydraulic performance can affect productivity. An incorrect setup can lead to unsafe working conditions, which is a significant concern. Striving for optimal performance requires constant attention to detail.

Hydraulic cylinders are crucial for many equipment. They harness fluid pressure to create motion. Routine maintenance is key for ensuring safety and efficiency. Check for leaks regularly. Wear and tear can lead to failure. Any sign of damage needs immediate attention.

Safety measures should never be overlooked. Operators must be trained to understand the machinery. They should wear protective gear while working. Understanding the risks can prevent accidents. Keep the work area clean and organized. A cluttered space can lead to mishaps.

Fluid levels should always be monitored. Low fluid can cause erratic movements. Inspect seals and hoses frequently. Even minor issues can escalate. Regular inspections can save time and resources later. Maintenance might seem tedious, but it’s vital for safe operations. A proactive approach is better than dealing with emergencies.

| Dimension | Description | Typical Value |

|---|---|---|

| Bore Diameter | The internal diameter of the cylinder where hydraulic fluid is pushed. | 30 - 200 mm |

| Rod Diameter | The external diameter of the piston rod that extends out of the cylinder. | 15 - 100 mm |

| Stroke Length | The distance the piston travels when the cylinder is actuated. | 100 - 1500 mm |

| Operating Pressure | The maximum hydraulic pressure the cylinder can withstand. | 70 - 300 bar |

| Fluid Type | The type of hydraulic fluid recommended for optimal performance. | Mineral oil-based fluids |

| Cycle Life | Estimated number of cycles the cylinder can perform under rated conditions. | 1 million cycles |

| Safety Features | Built-in safety measures such as pressure relief valves. | Pressure relief valve, burst disk |