+86-13349293098

+86-13349293098

01

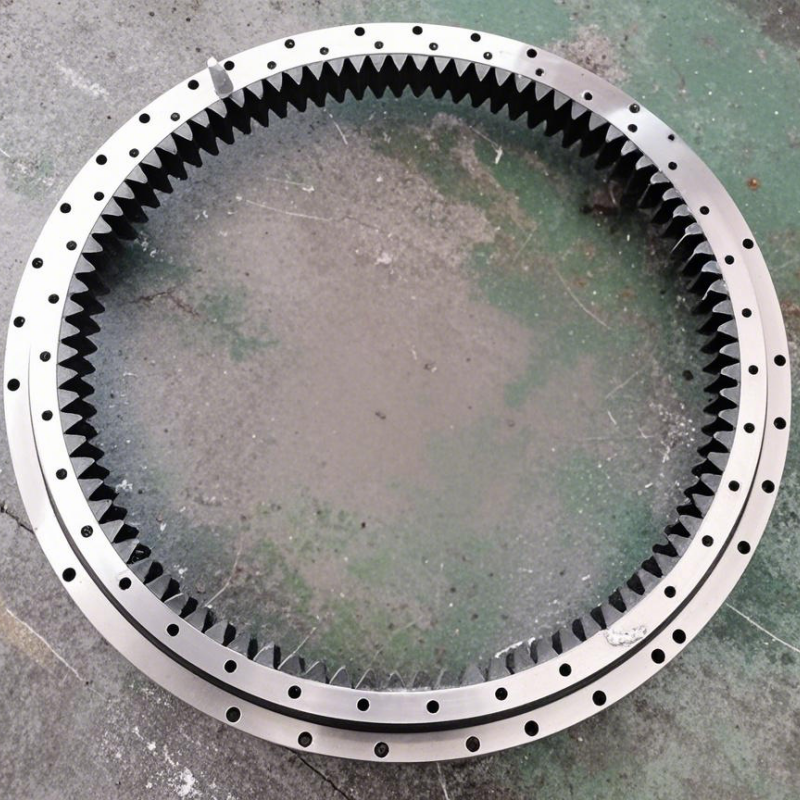

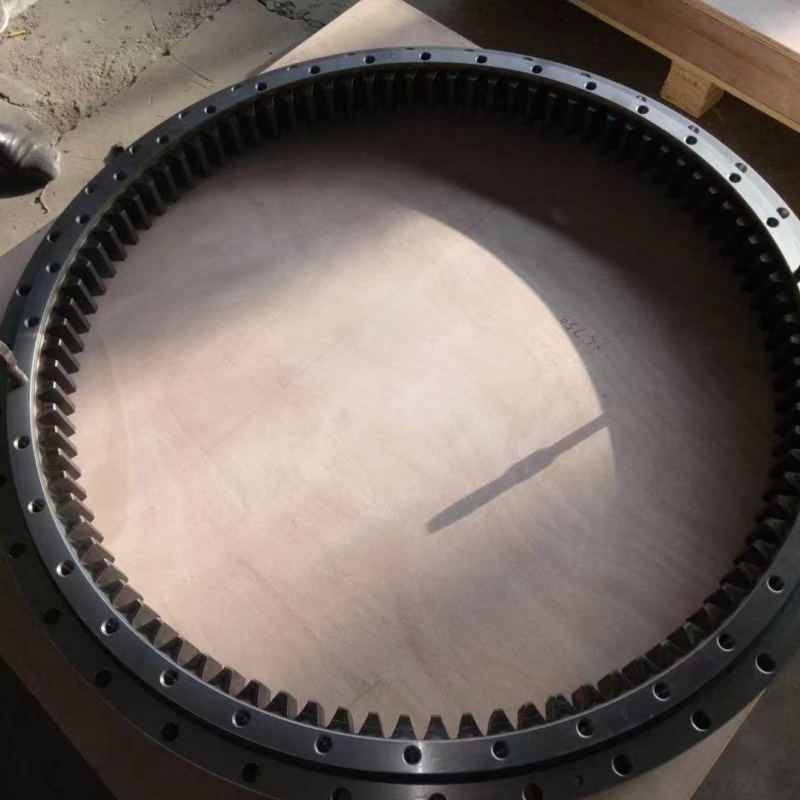

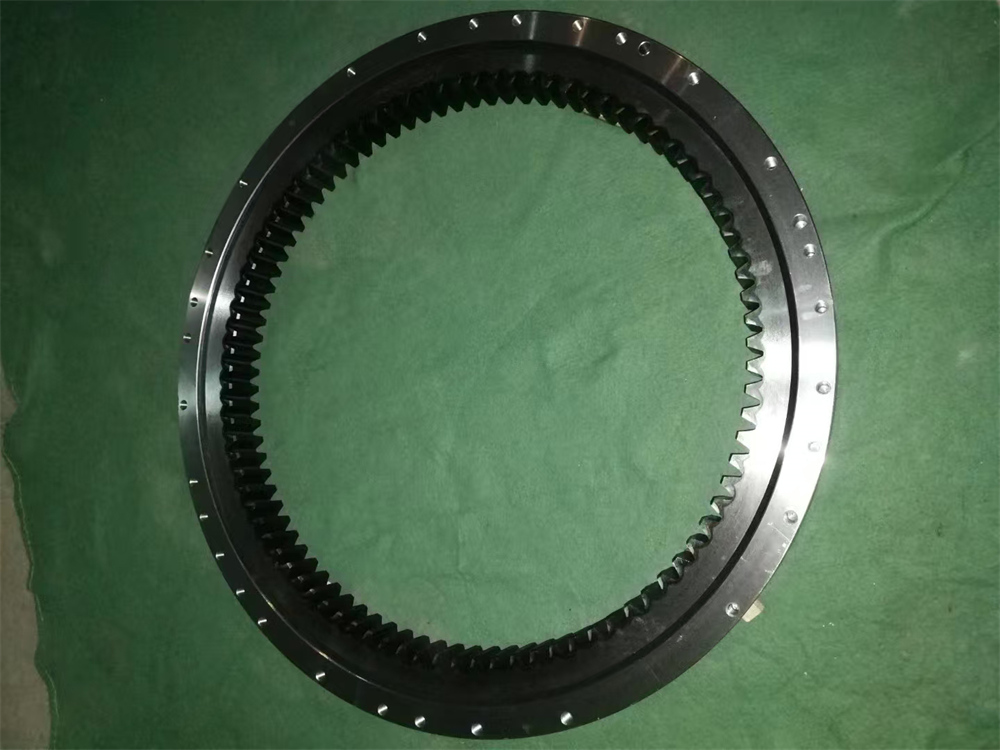

Hitachi Excavator EX60-5 Slewing Bearing 43767553

Company introduction

Our company is specialized in the wholesale and retail of bulldozers.excavators and other construction machinery and parts.Welcome Inquiry for deeper business talking. and sincerely hope we could establish a long term and best cooperation with you .

1)Undercarriage spare parts: Track shoe Track Link. Bolt. Track roller.Carrier Roller.

Sprocket. Front Idler. Idler Cushion.

2)Engine spare parts: Cylinder Head. Cylinder Block.Turbocharger. Piston. Piston Ring. Metal.

Crankshaft. Oil Pump. Fuel injection Pump. Water Pump. Alternator. Starting Motor

3)Hydraulic spare parts: Main Valve. Main Pump. Solenoid Valve. Boom/Arm/Bucket Cylinder.

Final Drive. Travel Motor. Swing Machinery. Swing Motor

4)Operator's Cab spare parts: Cab Ass'y. Monitor. Controller. Engine Controller. Wiring Harness.

Seat. Air Conditioner. Air Compressor.

Product Model List

|

Hitachi |

|||

|

Model |

Part Number |

Model |

Part Number |

|

EX60-2 |

4193433 |

ZX230 |

9154037 |

|

EX60WD -2 |

4193433 |

ZX230 |

9159646 |

|

EX60-5 |

43767553 |

ZX240 |

9196732 |

|

EX100 |

9098995 |

ZX240 |

9245728 |

|

EX100-3 |

9102726 |

EX300-3 |

9112188 |

|

ZX135 |

9184497 |

ZX330LC-5G |

9245698 |

|

EX150-5 |

9146953 |

ZX350-3 |

9245698 |

|

EX200 |

9098993 |

ZX370 |

9166468 |

|

ZX200LC-5G |

9260971 |

ZX370 |

9169894 |

|

ZX200-3 |

9260971 |

KH180-3 |

9099074 |

|

EX200-3 |

9148123 |

HE6010B |

1214DBS110T |

|

ZX200 |

9196732 |

EX400 |

164-2568 |

|

ZX200-5G |

9260971 |

EX400-5 |

9129521 |

|

EX200 |

9102727 |

ZX450 |

9129521 |

|

EX210-5 |

9102727 |

ZX450-3 |

9247287 |

|

ZX210LCK |

9169646 |

ZX450-3 |

9247287 |

|

ZX210W-1 |

9275368 |

ZX470-3 |

9247287 |

FQA

1. Q: How do you handle customer complaints regarding slewing bearings?

A: We have a dedicated customer service team. Once we receive a complaint, we will respond within 24 hours, conduct a thorough investigation, and provide a solution within 5 working days.

2. Q: Can your slewing bearings be used in high - speed rotation applications?

A: Yes, some of our slewing bearings are specifically designed for high - speed rotation applications. We use advanced lubrication and structural designs to ensure smooth and stable operation at high speeds.

3. Q: What kind of lubrication methods do your slewing bearings adopt?

A: Our slewing bearings use a combination of grease and oil lubrication methods. Grease lubrication is suitable for general working conditions, providing long - lasting protection, while oil lubrication is applied in high - speed or heavy - load scenarios for better heat dissipation and friction reduction. We also offer customized lubrication solutions based on specific usage requirements.

4. Q: Can your slewing bearings be integrated with monitoring systems?

A: Absolutely. We can equip our slewing bearings with sensors for real - time monitoring of parameters like temperature, vibration, and load. This allows for early detection of potential issues, enabling predictive maintenance and improving overall equipment reliability.

5. Q: How do you ensure environmental friendliness in production?

A: We comply with international environmental standards throughout the production process. Our factory uses energy - efficient equipment, recycles waste materials, and minimizes emissions. Additionally, the materials we select for slewing bearings are environmentally safe and recyclable.

Transportation way

1.Standard wooden case or cartonbox

2.Safety for long-distance transportation

3.All of the productions will be checked carefully before delivery

Product Display

Hefei King Slewing Bearing Technology Co., Ltd.

If you have any needs, please feel free to contact me and I will be happy to serve you.