+86-13349293098

+86-13349293098

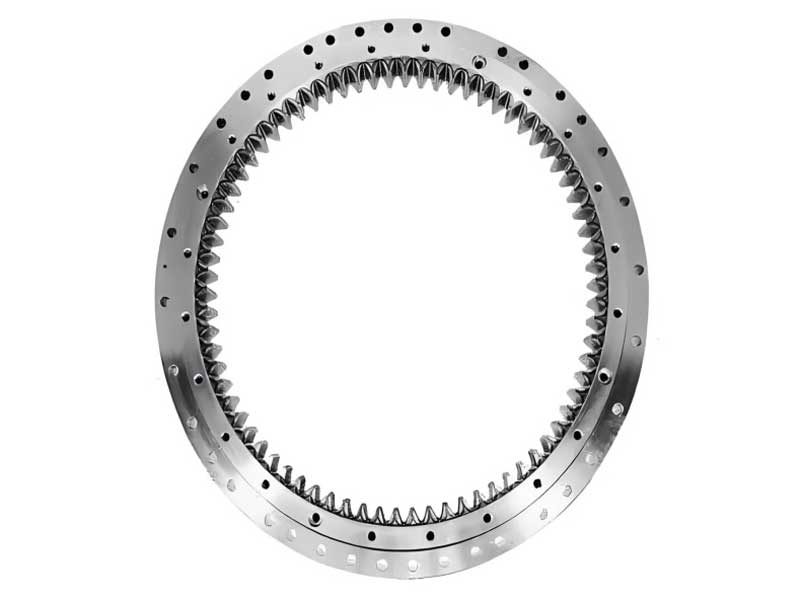

The Product Advantages of Slewing Bearings

Slewing bearings have the following advantages:

(1)High load-bearing capacity: With excellent design and material selection, slewing bearings can withstand large axial and radial loads as well as overturning moments. They are suitable for heavy-duty applications. For example, port cranes can carry loads ranging from several tons to dozens of tons and rotate stably.

(2)High precision: The rolling elements and raceways are precisely matched, resulting in high slewing accuracy and extremely small errors. This is crucial for equipment that requires high-precision rotation, such as radar antennas and optical inspection equipment.

(3)Strong reliability: Thanks to high-quality materials, advanced manufacturing processes, and strict inspection procedures, slewing bearings can operate stably for a long time in harsh industrial environments such as high temperatures, high humidity, and dusty conditions. This reduces the occurrence of breakdowns and downtime, and lowers maintenance costs.

(4)Compact structure: Compared with traditional devices, slewing bearings have a compact structure and occupy less space, which is conducive to the miniaturization and lightweight design of equipment. They have significant advantages in scenarios where space is limited, such as the slewing platforms on the decks of small ships.

(5)Smooth operation: Slewing bearings adopt the method of rolling friction, with a small friction coefficient, which enables smooth rotational movement and reduces vibration and noise. This not only improves the working efficiency of the equipment but also reduces the noise in the operator's working environment. At the same time, it also helps to extend the service life of the equipment.

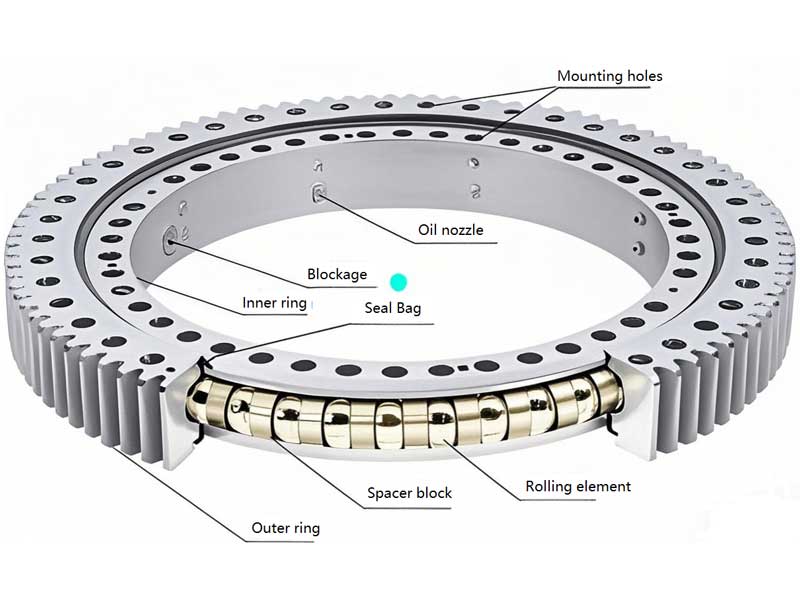

(6)Convenient installation and maintenance: With a standardized design and unified installation interfaces, slewing bearings are easy to install and disassemble. Their internal structure is simple. For daily maintenance, it only requires regular greasing and inspection of wear conditions.