+86-13349293098

+86-13349293098

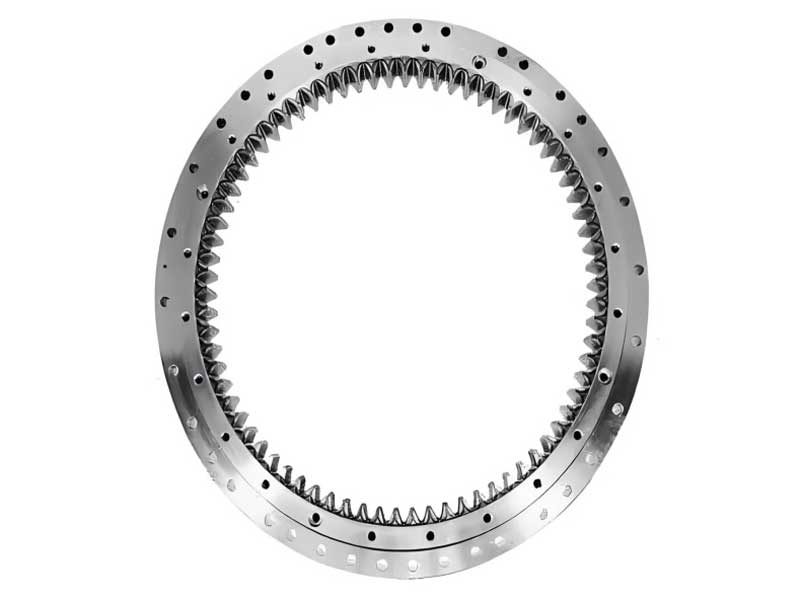

What is a Slewing Bearing?

A slewing bearing, also known as a slewing ring or turntable bearing, is a type of rotary rolling bearing. It is mainly used to support combined loads that are heavy and rotate slowly or oscillate slowly. These loads include axial forces, radial forces, and moment loads.

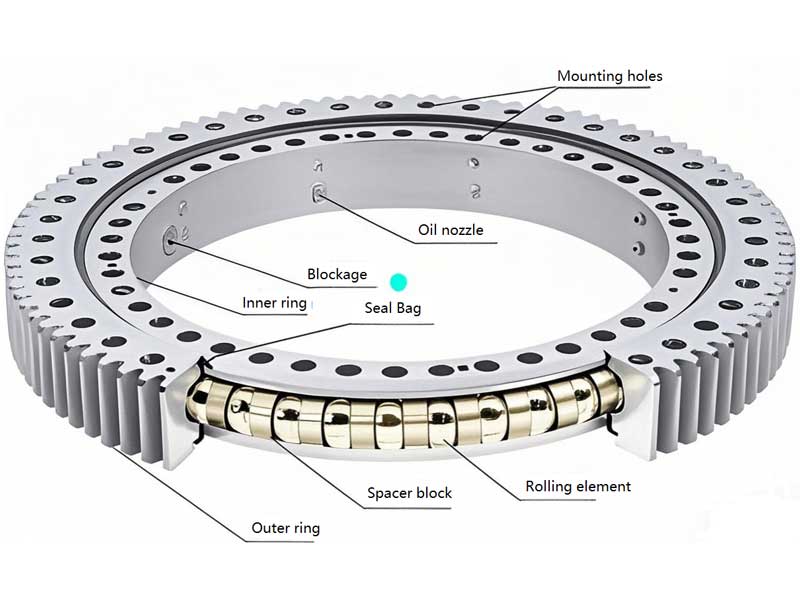

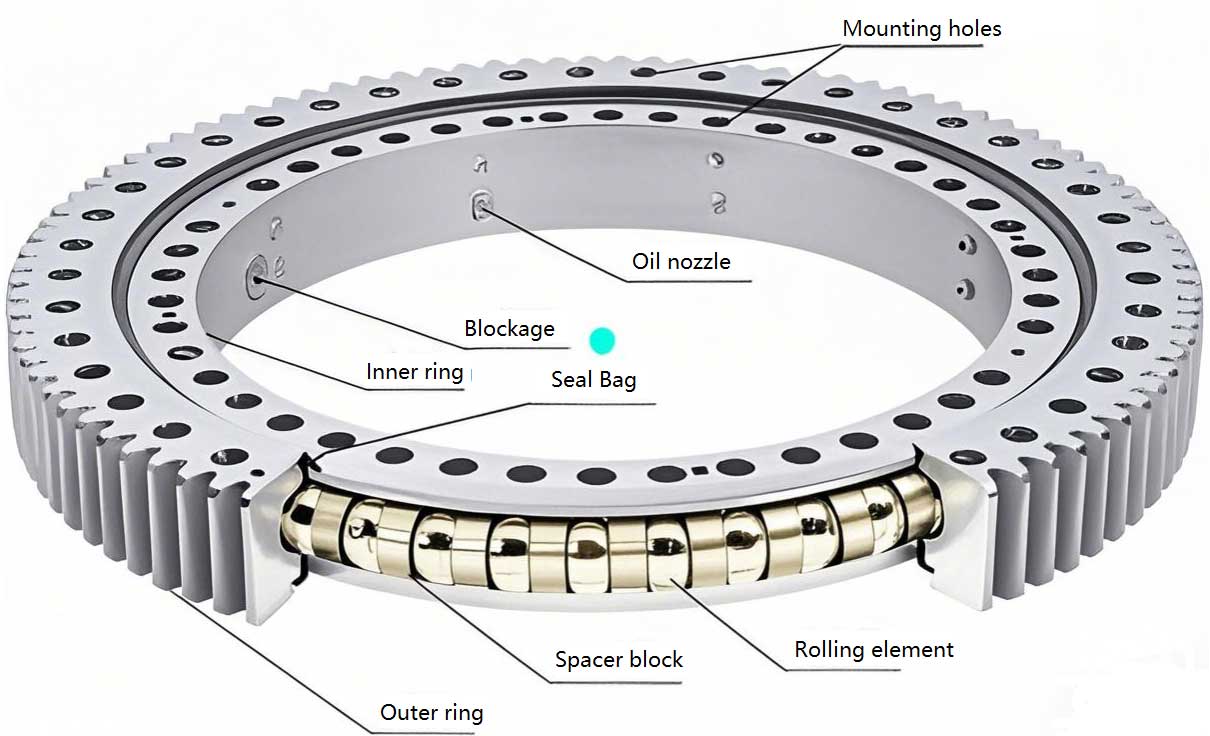

It is composed of multiple key parts. The inner and outer rings are the main structural framework. Usually made of high - strength alloy steel and subjected to special heat treatment, they have good wear - resistance and strength, and can withstand axial forces, radial forces, and overturning moments.

The mounting holes are used to fix the slewing bearing to mechanical equipment with bolts, ensuring a firm connection. The grease nipple serves as a channel for injecting grease, which can lubricate internal components such as rolling elements, reducing friction and wear. The plug closes the grease nipple when lubrication is not required, preventing impurities from entering. The sealing strip can effectively block dust, moisture, and other impurities from entering the interior of the slewing bearing, protecting components like rolling elements and raceways, and extending the service life.

The spacers keep the rolling elements at an appropriate distance, avoiding mutual collision, ensuring uniform distribution of the rolling elements, and making the slewing bearing operate more smoothly. The rolling elements roll between the raceways of the inner and outer rings, achieving low - friction rotary motion. They are the key components for the slewing bearing to realize its rotation function. The teeth on the outer ring can cooperate with other gears to achieve power transmission and the rotation of the equipment.

Slewing bearings are widely used in fields such as construction machinery, wind power equipment, and port machinery, providing reliable support for the slewing motion of these devices.