+86-13349293098

+86-13349293098

01

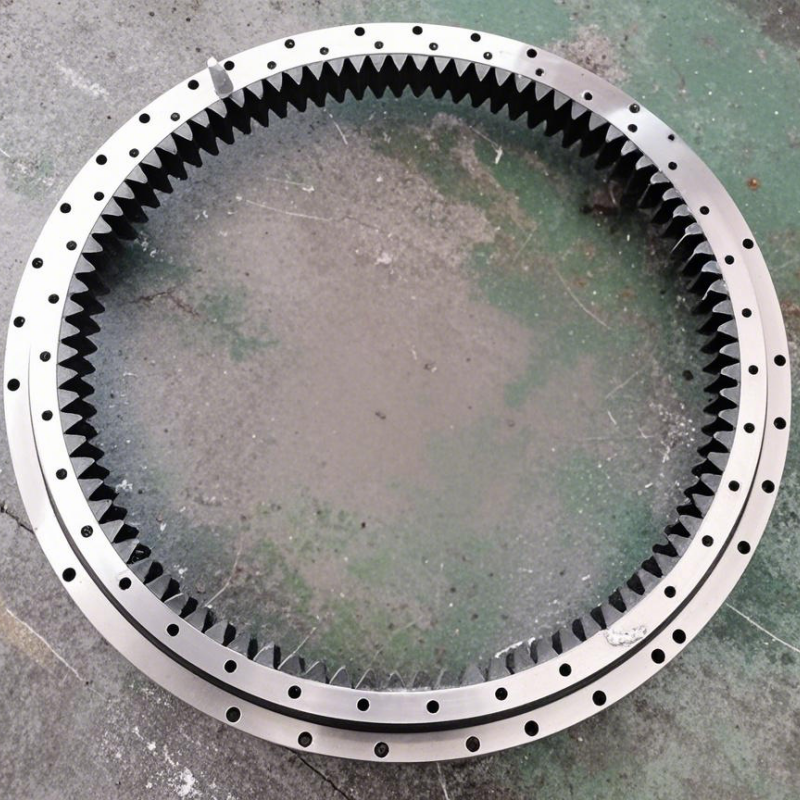

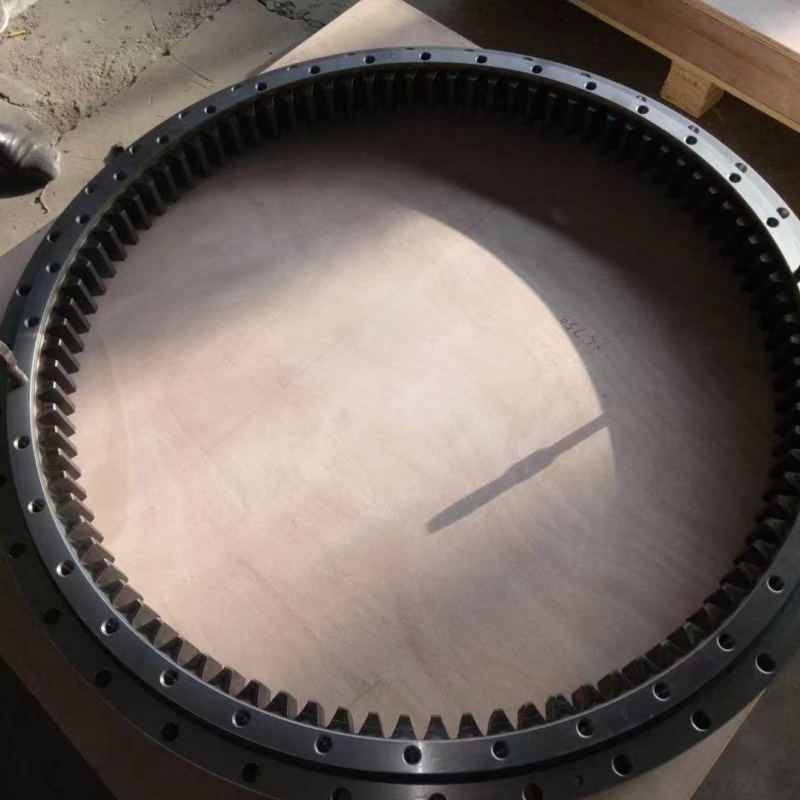

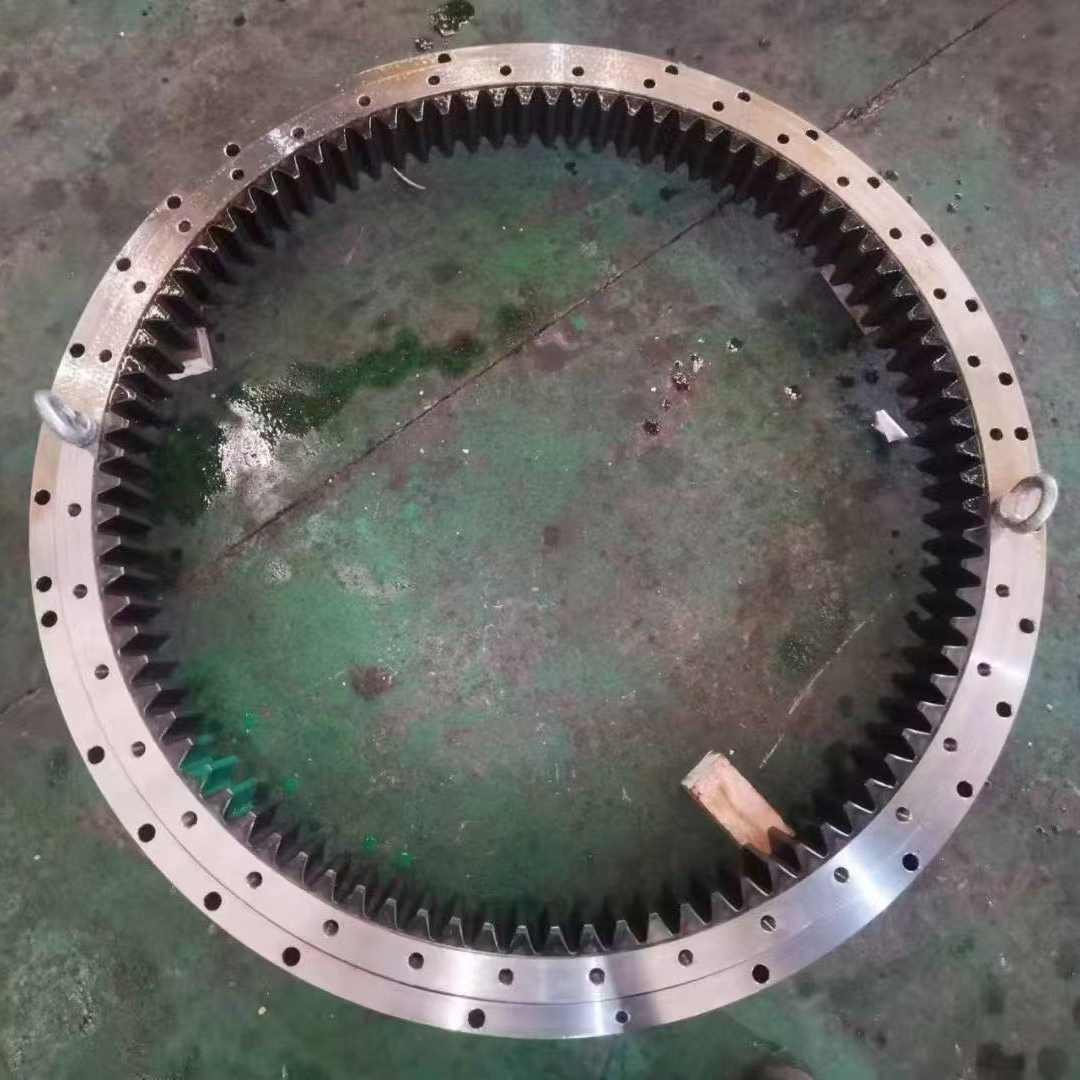

SK200-8 Slewing Ring YN40F00026F2 Kobelco Excavator

Why choose us

-

Cutting - Edge Manufacturing Capabilities

Our in - house factory is outfitted with the latest CNC machinery, including vertical lathes, gear hobbing machines, gear shaping machines, hole drilling machines, quenching machines, vertical grinding machines, and turning machines. This advanced setup not only enables us to meet tight delivery schedules but also guarantees consistent production of high - quality slewing rings. With our capabilities, we prioritize both speed and excellence in every product we manufacture. -

Unrivaled Technical Expertise

Backed by a team of engineers with more than 20 years of dedicated experience in excavator slewing ring research and development, we bring unparalleled know - how to every project. Our professional measuring team offers an exclusive service: upon request, we deploy experts to customer job sites to meticulously measure worn - out or damaged slewing rings. This ensures that our replacement parts are an exact match, minimizing downtime and enhancing equipment performance..

Company Introduction

Nestled in Hefei, Anhui Province, Hefei King Slewing Bearing Technology Co., Ltd. has firmly established itself as a leading manufacturer and exporter of excavator slewing rings. Our advantageous location near Shanghai Port provides us with seamless access to global markets, ensuring swift and efficient product delivery worldwide.

Product Model List

|

Kobelco |

|||

| Excavator model number | Part number | Excavator model number | Part number |

| SK60-3 | 2425U232F1 | SK210LC-6 | Yn40F00004f1 |

| SK75-8 | YT40F00004F1 | SK210LC-8 | YN40F00026F1 |

| SK75 UR-3 | 2425U261F1 | SK220LC III/IV | 24100N7441F1 |

| SK130LC IV | LP40FU0001F1 | SK230-6 | LQ40F00004F1 |

| SK135SR | YW40F00001F1 | SK235 | YN40F01004P1 |

| SK-140 | YY40F00009F1 | SK250-6E | LQ40F00005F1 |

| SK140SR | YY40F00009F1 | SK250-8 | LQ40F00014F1 |

| SK200 | 24100N7440F1 | SK250LC-6E | LQ40F00004f1 |

| K907LC-2 | 24100N3978F | SK250NLC-6 | 24100N7441F1 |

| SK907-2 | 24100N3978F2 | SK260-8 | LQ40F000014F1 |

| SK200 | YN40FU0001F1 | SK260LC-8 | LQ40F00014F |

| SK200-3 | 24100N440F1 | SK300-III | 2425U262F1 |

| SK200-6 | YN40F00008F1 | SK330 | LC40F00019F1 |

| SK200-6 | YN40F00020FI | SK330-6E | LC40F00009F1 |

| SK200-6 super | YN40F00004F2 | SK330LC V1 | LC40FU0001F1 |

| SK200-8 | YN40F00026F1 | SK330LC-6E | LC40F00009F1 |

| SK200-8 | YN40F00026F2 | SK330-6E | LC40F00012F |

| SK200-10 | Yn40F00042f2 | SK350 | LC40F00018F1 |

| SK-210 | YN40F00033F2 | SK350ME | FG4E9648E-J6 |

| SK210LC | YN40F00019F2 | SK480LC-6 | LS40F00003F1 |

FAQ

1. Q: Do you offer training services for slewing bearing operation and maintenance?

A: Yes, we provide comprehensive training programs for our customers. These cover proper operation, routine maintenance, and troubleshooting techniques for slewing bearings. Our training can be conducted online or on - site, tailored to the specific needs of your team.

2. Q: What is your production capacity per month?

A: Our monthly production capacity can reach [X] units, which can be flexibly adjusted according to order volumes. With our automated production lines and efficient workforce, we can meet both large - scale and urgent orders.

3. Q: Can you supply slewing bearings with special anti - corrosion coatings?

A: Yes, we offer various anti - corrosion coatings, including zinc plating, epoxy coating, and specialized anti - rust paints. These coatings significantly enhance the lifespan of slewing bearings in corrosive environments, such as marine or chemical industries.

4. Q: How do you manage the supply chain for raw materials of slewing bearings?

A: We maintain long - term partnerships with reliable raw material suppliers who meet our strict quality standards. Through regular audits and performance evaluations, we ensure stable material supply. Additionally, we keep a strategic inventory to prevent shortages and can quickly adapt to fluctuations in demand.

5. Q: Are your slewing bearings suitable for low - temperature environments?

A: Yes, we have developed slewing bearings specifically designed for low - temperature conditions. By using special low - temperature - resistant materials and lubricants, our bearings can maintain excellent performance even in extremely cold climates, ensuring smooth operation without brittleness or freezing issues.

Product Display

Hefei King Slewing Bearing Technology Co., Ltd.

If you have any needs, please feel free to contact me and I will be happy to serve you.