+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

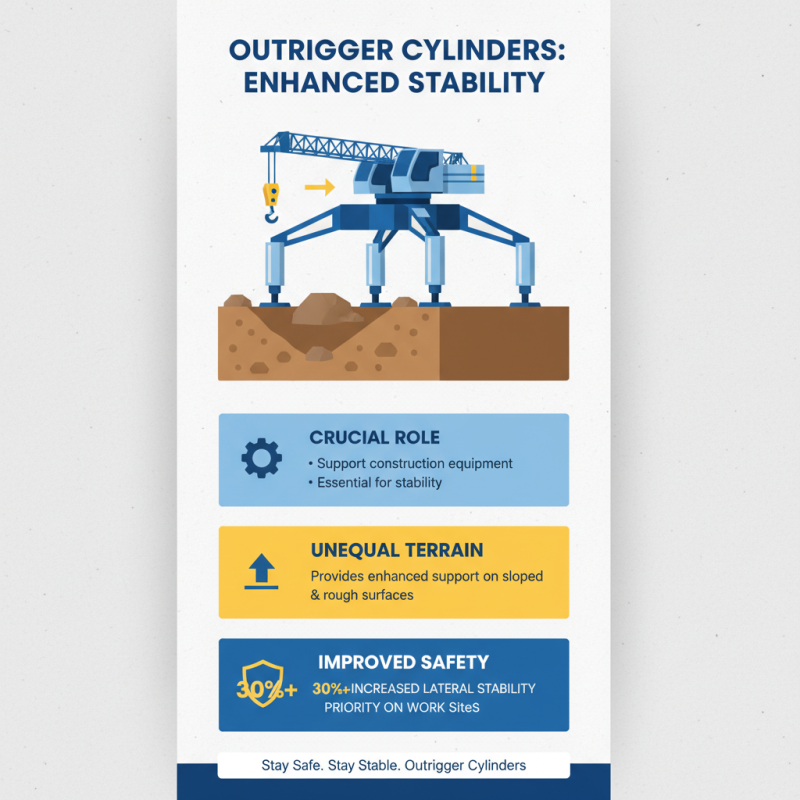

Outrigger cylinders play a vital role in enhancing stability and safety for various machinery. According to a recent industry report, 75% of construction accidents result from equipment instability. This underlines the importance of reliable outrigger systems. Outrigger cylinders absorb the load effectively and provide necessary support, making them essential for lift trucks and cranes.

Data illustrates that proper use of outrigger cylinders increases operational efficiency by 40%. When deployed correctly, they can minimize risk, improving site safety significantly. However, challenges persist. Operators often overlook maintenance, leading to potential failures. Regular inspections can mitigate such risks and extend the lifespan of these critical components.

Moreover, it is crucial to stay updated with technological advancements in outrigger design. Newer models offer advanced features, such as automated deployment systems. Ignoring these improvements could hinder performance. Understanding the benefits of outrigger cylinders not only ensures safe operations but also promotes a proactive approach to machinery management. This awareness can lead to better decision-making in the field.

Outrigger cylinders play a crucial role in construction equipment stability. They provide enhanced support, especially when working on uneven terrain. Studies indicate that equipment using outrigger cylinders can improve lateral stability by over 30%. This is significant when safety is a priority on job sites.

Another advantage is their ability to reduce load shifts. When lifting heavy materials, consistent stability is essential. Outrigger cylinders allow for a controlled lifting process, minimizing the risk of accidents. Reports suggest that improper load handling causes roughly 30% of construction-related injuries. Implementing outrigger cylinders can greatly mitigate this risk.

Furthermore, their design often allows for easy adjustment. Operators can rapidly deploy them, enhancing operational efficiency. Quick adjustments may lead to increased productivity. However, proper training is crucial. Misuse due to lack of knowledge can lead to potential hazards. Clear guidelines for operators are essential to maximize the benefits of outrigger cylinders.

Outrigger cylinders are crucial for improving stability in various equipment. They provide a solid base, allowing machines to operate safely on uneven terrain. This reduction in tipping risk significantly enhances safety for operators and bystanders. The added stability prevents unnecessary accidents and machinery damage, creating a safer work environment.

Tips: Always inspect outrigger cylinders regularly. Small leaks or damages can compromise stability. Pay attention to the ground surface where you park the equipment. Uneven surfaces can still pose risks even with reliable outriggers.

Operators must practice caution. Stability is essential, but it shouldn’t create complacency. Proper training is vital to maximize the benefits of outrigger cylinders. Encourage teamwork to monitor equipment placement, especially in challenging environments. Remember, safety relies on more than just technology; awareness and communication matter too.

| Benefit | Description | Impact on Safety |

|---|---|---|

| Enhanced Stability | Outrigger cylinders extend the base of the equipment, lowering the center of gravity. | Reduces the risk of tipping over during operation. |

| Load Distribution | Helps evenly distribute weight across the equipment's frame. | Minimizes structural stress, enhancing durability and safety. |

| Increased Work Area | Allows for a larger operational footprint, improving accessibility. | Improves safety by enabling more comfortable working conditions. |

| Enhanced Precision | Offers better control and precision during lifting operations. | Lowers the chance of accidents due to operator error. |

| Improved Operator Confidence | Reduces fear during operation due to enhanced stability. | Encourages safer practices and better decision-making. |

| Versatility | Can be used in various terrains and conditions. | Ensures safety across diverse operational environments. |

| Reduced Ground Pressure | Distributes the load over a larger area, reducing pressure. | Prevents ground failure and equipment sinkage. |

| Operational Efficiency | Allows faster setup and breakdown of equipment. | Saves time and enhances safety protocols. |

| Cost-Effectiveness | Reduces maintenance costs associated with wear and tear. | Improves the long-term safety and reliability of equipment. |

| Regulatory Compliance | Meets safety standards in various industries. | Ensures operations succeed within legal safety parameters. |

Outrigger cylinders have gained attention for their cost efficiency. These hydraulic components play a crucial role in various heavy machinery applications. According to a report by the International Society for Automation, organizations can reduce operational costs by up to 15% when utilizing efficient hydraulic systems.

The initial cost of outrigger cylinders may seem high. However, their durability and low maintenance needs can lead to significant savings over time. A study by the Hydraulic Institute reveals that companies typically save around $3,000 annually per machine due to reduced downtime and maintenance. Using these cylinders can thus turn out to be a wise investment.

Moreover, operational efficiency can improve with the right application of outrigger cylinders. The smooth operation reduces energy consumption, an essential factor in today’s market. Energy-efficient systems are reported to lower energy costs by approximately 20%. However, the challenge remains in optimizing their use—improper installation or misuse can negate these benefits. Continuous training and adaptation are needed for maximizing the return on investment.

Outrigger cylinders are essential in various industries. They provide stability and support. Construction sites benefit greatly from these systems. Equipment operates safely on uneven ground. The versatility of outrigger cylinders allows them to adapt to different tasks.

In the marine sector, outriggers ensure that vessels remain steady during loading and unloading. This stability is crucial for safety. In entertainment, they are used in staging setups. A dynamic performance requires secure support structures. Yet, some may overlook the need for proper maintenance. This can lead to unexpected failures, which could be costly.

Road maintenance and utility work also utilize these cylinders. They enable efficient operation in tight spaces. However, they aren't foolproof. Operators must be trained properly. Misuse can lead to dangerous situations. It's essential to reflect on safety protocols regularly. Balancing efficiency and safety is crucial every day.

Outrigger cylinders are essential for stability in various applications. Proper maintenance is crucial for their longevity. Regularly inspect the cylinder for any signs of wear or damage. Keep the cylinder clean to avoid debris accumulation. Corrosion can be a silent enemy, so proactive measures are vital.

Here are a couple of tips for better care:

Observe the environment where the outrigger operates. Harsh conditions can accelerate wear and tear. Consider protective covers to shield the cylinders from elements. While these actions require effort, the rewards are worth it. Regular maintenance ensures safety and operational efficiency.